Description

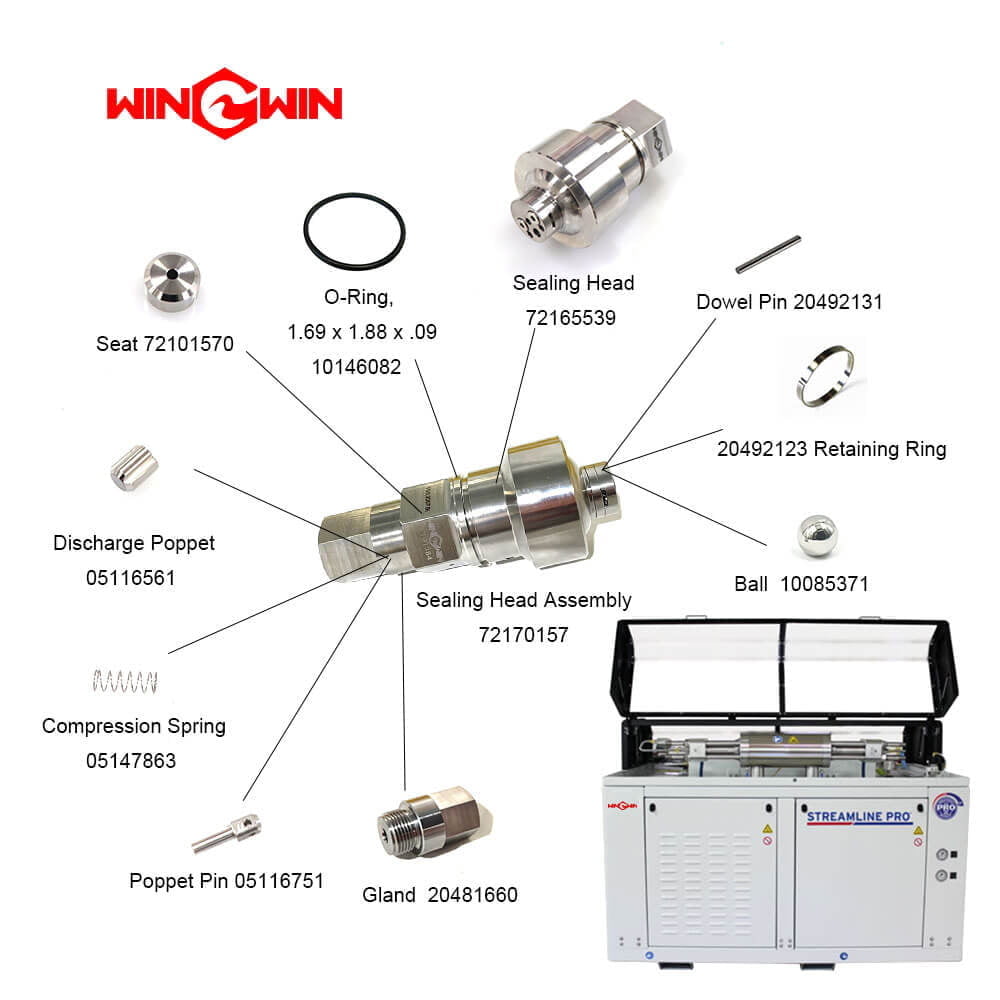

Dowel Pin 20492131 applied to 125HP pump

Item | Part Number | Description | Quantity | Item | Part Number | Description | Quantity |

1 | 05146592 | Gasket, Topworks Support | 2 | 14 | 72162253 | Plunger | 2 |

2 | 20476377 | Support, Topworks | 2 | 15 | 05130091 | Hydraulic Seal Cartridge | 2 |

3 | 10118206 | O-Ring, 1.31×1.56× .13 | 2 | 16 | 72175989 | Bushing Retainer Flange | 2 |

4 | 05144514 | Hydraulic Cylinder | 1 | 17 | 72158494 | UHP Seal Assembly | 2 |

5 | 05098991 | Socket Head Screw, 3/8-16×3-3/4 | 8 | 18 | 72166738 | UHP Cylinder | 2 |

6 | 95688743 | Lock Washer, .38 | 8 | 19 | 72163802 | Liner | 2 |

7 | 72101190 | Piston Assembly | 1 | 20 | 20474325 | Stud, 1-1/8-12×18.31 | 8 |

8 | 10074771 | O-Ring, 5.25×5.50× .13 | 2 | 21 | 72170157 | Sealing Head Assembly | 2 |

9 | 05120092 | Backup Ring, 5.25×5.50× .13 | 2 | 22 | 72178493 | Flange Assembly | 2 |

10 | 72175997 | Hydraulic Cylinder Head | 2 | 23 | 20464590 | Flat Washer, 1.13 | 8 |

11 | 05097886 | Socket Head Screw, 3/4-16×2-1/4 | 12 | 24 | 20461761 | Hex Nut, 1-1/8-12 | 8 |

12 | 05144183 | Spacer Assembly, Proximity Switch | 2 | 25 | 20489339 | Adapter, JIC/Pipe, 50× .38 | 1 |

05144191 | O-Ring, .69× .88× .09 | 26 | 72176756 | O-Ring, 3.88×4.25× .19 | 6 | ||

13 | 72141569 | Kit, Proximity Switch | 2 | ||||

| 72134224 | Proximity Switch | ||||||

95119012 | Socket Head Screw, 1/4-20×1 |

Dowel pins are small cylindrical pins that are used to precisely align and connect two parts together.

In a 125HP pump, dowel pins are used to align and secure various components of the pump, such as the intensifier block, hydraulic manifold, or other parts.

Dowel pins can help to ensure that components are aligned correctly during assembly and that they maintain their alignment during operation.

Precise alignment of components is critical to ensure that the pump operates smoothly, efficiently, and safely.

When installing or replacing dowel pins in a 125HP pump, it is important to use the correct size and type of pin that is designed for the specific application and manufacturer’s specifications.

It is also important to follow our manufacturer’s recommended procedures for installation and alignment of components to ensure that the 125HP pump operates safely and efficiently.

1. Types of dowel pins

Dowel pins can be made of different materials, containing steel, stainless steel, and brass. They can also be solid or hollow, and may have grooves or other features to improve their grip and alignment.

2. Alignment accuracy

Dowel pins are used to achieve high accuracy in the alignment of components.

In a 125HP pump, this is important to ensure that the high-pressure water stream is directed precisely and accurately.

3. Installation

Dowel pins are installed into pre-drilled holes in the parts being joined.

The pins are then driven through the holes and into corresponding holes in the mating component.

The pins are typically a press fit, meaning they are held in place by friction and do not require additional fasteners.

4. Benefits

The use of dowel pins in a 125HP pump provides several benefits, including improved alignment accuracy, reduced wear and tear on components, and improved efficiency and reliability of the pump.

5. Maintenance

Over time, dowel pins may become worn or damaged and require replacement.

What are the common causes of dowel pin wear and damage in a 125HP pump?

Dowel pins in a 125HP pump are subject to wear and damage over time due to varieties of factors.

Here are some common causes of dowel pin wear and damage:

1. Misalignment during assembly

If the components are not properly aligned during assembly, the dowel pins may experience excessive wear or damage.

2. Vibration

Vibrations caused by the operation of the 125HP pump can cause the dowel pins to wear or loosen over time.

This can result in misalignment of the components and reduced efficiency of the 125HP pump.

3. Corrosion

Corrosion can occur because of exposure to moisture or other environmental factors.

This can cause the dowel pins to become weak and brittle, leading to failure or breakage.

4. Overloading

If the 125HP pump is overloaded or subjected to excessive forces, the dowel pins may become stressed and damaged.

5. Improper maintenance

Improper maintenance can also contribute to dowel pin wear and damage.

6. Material

The material used to make the dowel pins can affect their lifespan and performance.

For example, stainless steel dowel pins are more resistant to corrosion than carbon steel dowel pins.

7. Load capacity

The load capacity of the dowel pins should be appropriate for the application.

If the dowel pins are subjected to excessive loads, they may become stressed and damaged.

8. Lubrication

Proper lubrication can help to reduce wear and damage to the dowel pins.

Make sure to use the recommended lubricants and follow our lubrication guidelines.

9. Environmental factors

Environmental factors such as temperature, humidity, and exposure to chemicals or corrosive substances can have influence on the lifespan and performance of dowel pins.

10. Installation and alignment

Proper installation and alignment of the dowel pins are crucial to their performance.

Make sure to follow our recommended installation procedures and use the correct tools and techniques to ensure proper alignment.

Any other questions, please contact us.