Description

waterjet knowledge:about waterjet cutting process

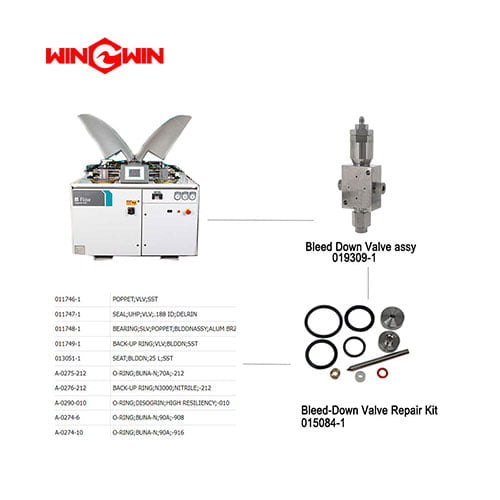

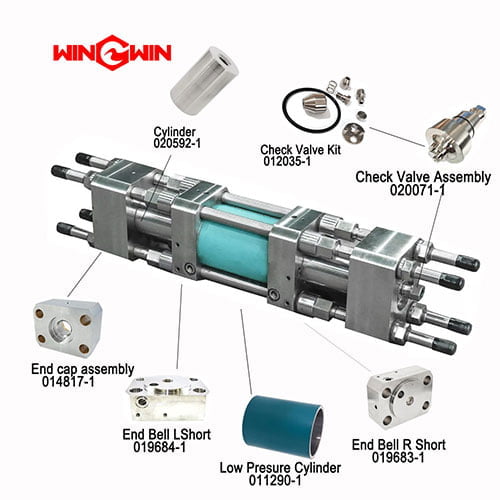

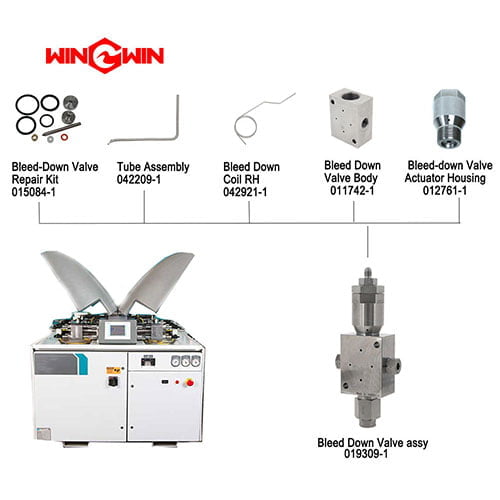

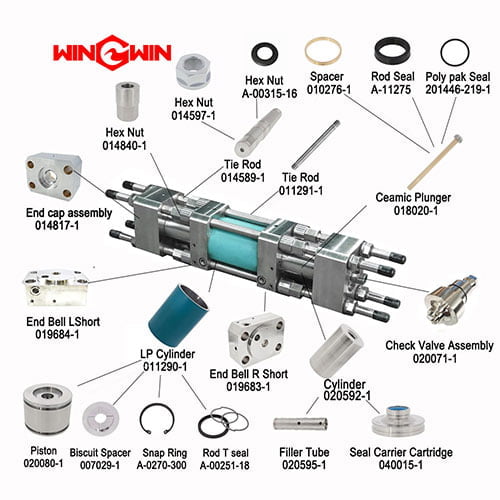

Waterjet cutting process for ceramics: Compared with traditional cutting tools and CNC machine tools, the easy-to-use waterjet cutting machine can effectively reduce the processing time for ceramic manufacturers. Abrasive waterjet cutters can cut any ceramic without changing tools. Its own start-up hole allows drilling into the material. It can open holes in most materials without special consideration. For specific fragile and brittle materials. Abrasive Waterjet cutting process will not cause thermal energy or surface deformation. The advantages of Waterjet cutting process in ceramics are obvious: first, the incision is flat, the cutting quality is high, and there will be no “burst” phenomenon on the upper edge of the incision after cutting; second, the cutting accuracy is high, the cutting accuracy reaches 0.1mm, and the seam is uniform, which can be used in very complex and beautiful jigsaw puzzles and murals. At the same time, the cutting efficiency is fast, the product consistency and interchangeability is excellent, not only can it realize the automatic nesting function but also improve the working environment and reduce the impact of dust.The picture is 94k waterjet parts,we have all 94k waterjet parts,if you have 94k waterjet cutting machine,you can contact us buy 94k waterjet parts,