Description

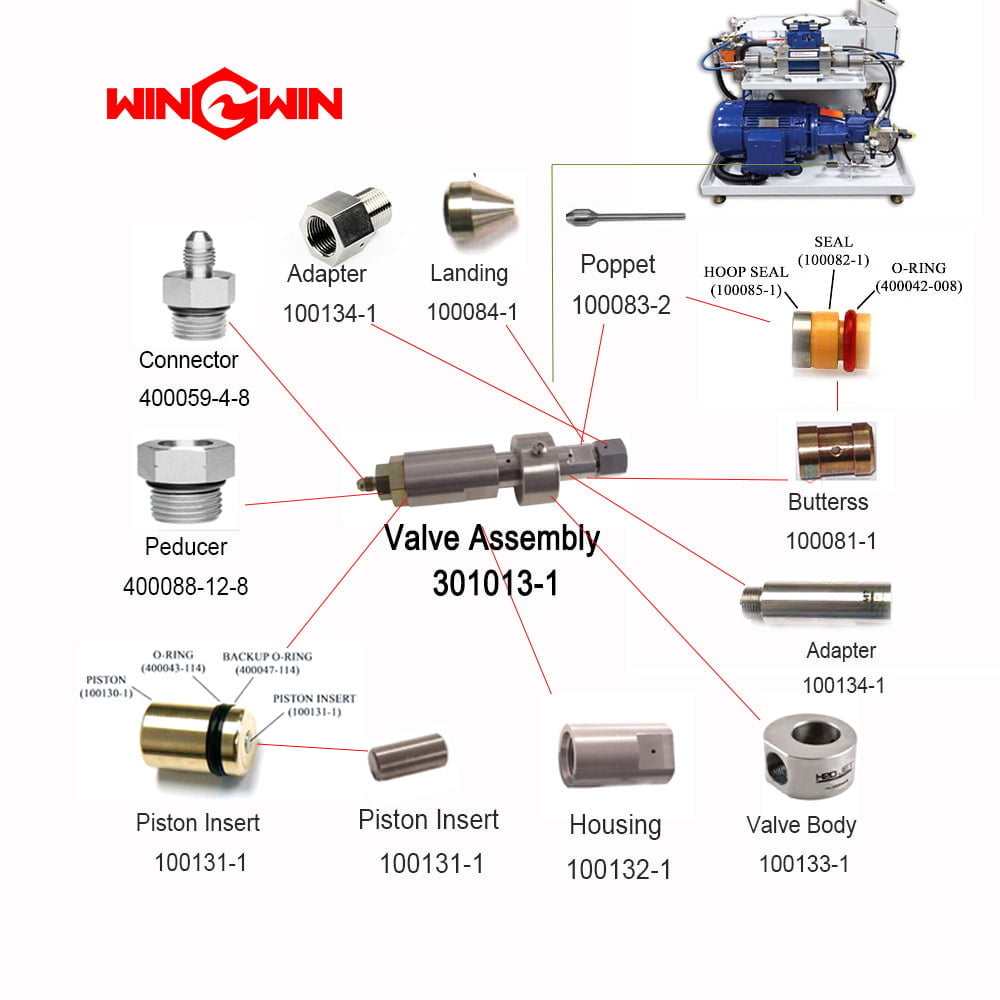

004694‑1 F-LOW Waterjet parts Bleed‑Down Valve Repair Kit

Bleed‑Down Valve Repair Kit

Bleed‑Down Valve Repair Kit

waterjet FAQ:

- Smaller sand particles (120 mesh abrasives or smaller) are slower to cut, but the surface is smoother (compared with 80 mesh or 60 mesh abrasives).

- If regular piercing of composite materials, glass, and stone is required, ensure that the system can use the controller to reduce or increase water pressure. At the same time, vacuum aids or other technologies should be checked to improve the chances of successful piercing of these brittle or laminated materials.

- Tap water is usually injected into the waterjetsystem. Before injecting tap water into the supercharger, we usually filter out the impurities in the water through the water filtration system. 90% of the water and sand water users need to soften the water. In this way, the water filter will not only greatly prolong the life of the outlet hole, but also improve the service life of the vulnerable parts of the turbocharger.

- Underwater cutting will reduce the possibility of frosting or “fogging” on the top surface of the water with sand. Underwater cutting will also greatly reduce jet noise and workplace chaos. The only disadvantage is that the operator can not clear the jet during the cutting process, so we can consider the electronic performance monitoring device. These monitoring devices can detect deviations from the optimal cutting performance and can shut down the system before the parts are damaged.