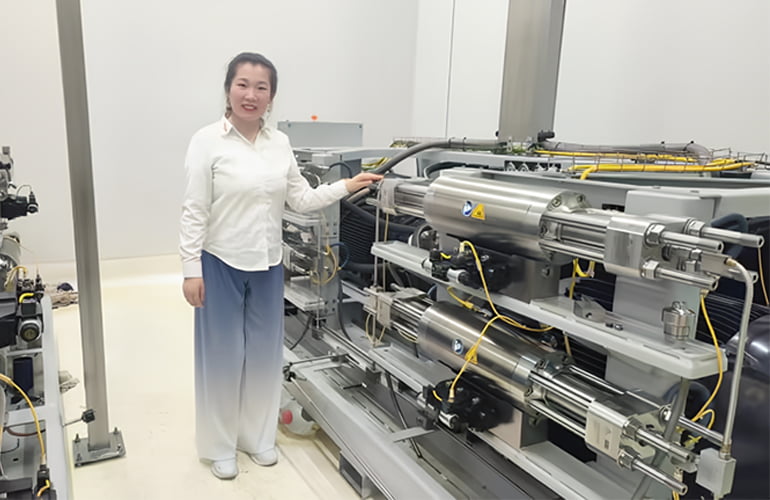

Machine de découpe au jet d’eau

Water is a kind of soft liquid. When water has a high flow rate, it can have a strong penetrating force. Waterjet cutting is successfully applied to the industrial field by taking advantage of this property. I believe that after you spend ten minutes reading this article, you will have a whole new understanding of waterjet cutting.

- Marble Cutting, Tile Cutting, Rock Plate Cutting, Stone Cutting

In the decoration industry, there is a kind of decoration is tile parquet. Different colors of tiles are cut to form a beautiful pattern and decorated on the ground or wall, which can make the whole decoration style more beautiful. Then the machine for cutting ceramic tiles is the waterjet cutting machine. Marble cutting, rock cutting and the countertop we use in the kitchen is artificial marble or natural marble, this kind of stone needs stitching, so if you are doing tile parquet, marble cutting or kitchen countertop decoration, you may need to use water cutting equipment.

In the glass industry, many places need waterjet cutting, such as the small round hole on the glass and cutting glass shaped patterns. Machine de découpe au jet d’eau of cutting glass has good practicability. The cutting edge is smooth, no burr and very safe. Waterjet cutting can cut 0.1ih-18in thick glass but can not cut toughened glass, otherwise it will cause glass

3. Metal Cutting

There are many kinds of metal, but the characteristics of waterjet cutting just meet the process requirements of metal cutting, iron, copper, aluminum, aluminum and so on. And the characteristics of waterjet cutting is cold cutting, which will not produce high temperature or let the metal metamorphism. Cutting metal is mostly Gaza cutting.

The real cutting medium is not water, it is sand. Tiny sand is a shape with multiple edges and corners, the real sense of sand wear materials, resulting in material fracture, this is Gaza waterjet cutting. This property is actually equivalent to saw blade cutting, or machine tool cutting, the greater significance is to avoid similar problems like material deformation and material deterioration caused by laser cutting or flame cutting.

Current advanced waterjet cutting machine technology can cut 12in thickness, brass can cut 10in.

4. Oil Pipeline Cutting, Natural Gas Cutting, Flammable Oil Pipe Cutting

In many projects, cutting oil pipelines, natural gas pipelines, flammable oil pipelines and other cutting is very dangerous, because it is easy to explode. In this industry, the engineering needs waterjet cutting equipment to cut. Waterjet cutting will not produce mars, while cutting at the same time water always exists, so it is very suitable for dangerous cutting.

The currentwaterjet cutting machine technology achieves remote cutting, which means the cutting head is installed on the material, then the operator remotely controls mobile device cutting, so as to ensure the safety of personnel. The size of the oil tank is very large, many times can reach a diameter of 30m. waterjet cutting machine can completely solve this problem and achieve remote perfect cutting

5. Plastic Cutting, Rubber Cutting

In the plastic cutting and rubber cutting industry, there are some processes need waterjet cutting machine. Plastic box rubber belongs to rubber products, when cutting can not produce heat and can not appear toxic smoke, which is a problem for cutting. Waterjet cutting in the process of cutting will not produce toxic gases. Meanwhile, the waste water can be treated, which is very beneficial for environmental protection,

0.1in-12in thickness of rubber, plastic can be cut off using waterjet cutting machine.

6. Foam Cutting, Sponge Cutting

In foam, sponge and other industries, the way to achieve cutting is often hot wire cutting, but for high-end processing technology, many customers choose waterjet cutting. Foam cutting and sponge cutting will produce more harmful substances, but waterjet cutting machine is safe, so many countries use waterjet cutting to cut foam, sponge and other similar materials.

The cutting thickness is 0.1in-20in. Pure water is used for cutting.

7. Textiles, Cloth, Composite Materials

In the textile industry, fire prevention is an important thing. Cutting textiles is mostly the use of stamping cutting, blade cutting and other physical cutting. Waterjet cutting is also a kind of physical cutting, it will not produce flame and harmful substances. This is a good choice for textile cutting.

It can cut 2in textiles.

8. Food Cutting

A lot of people are very skeptical, can waterjet cutting also cut food?

Yes, food can be cut by waterjet cutting machine, such as green vegetables, frozen fish, cakes, etc. Cutting green vegetables is often used in the kitchen assembly line. In the automatic kitchen, clean and sanitary cutting can be done by choosing waterjet cutting, like frozen fish and frozen meat, which can be cut without melting frozen meat, so as to ensure the quality of meat. waterjet cutting machine can ensure the perfect shape of the cake. And waterjet cutting machine can be used to cut steak instead of abrasive cutting.

9. Cement Board Cutting

Mass production of cement board needs to cut into standard small pieces, so waterjet cutting is very suitable for cement board cutting production line. Its multi-head application can be very good at the same time to cut multiple cement board into the same or different size of small pieces.

The cutting thickness can reach 15in.

In what industries is waterjet cutting used?

waterjet cutting machine has the characteristics many other cutting methods can not achieve, these characteristics have irreplaceable advantages. Let’s introduce the advantages of waterjet cutting machine in these industries:

1. The Aerospace Industry

Aerospace focuses on materials, many of which are customized metals, requiring light quality, high hardness, good toughness and other requirements. Once these materials are successfully produced, the characteristics of the material cannot be changed in the cutting process, which requires the use of cold cutting.

2. Medical Device Industry

Medical equipment is related to people’s health, its materials are also special materials. Water jet cutting provides high cutting precision and smooth surface. These materials will be developed and changed according to the needs, so it is very important to cut the material with waterjet.

3. Electronic Products Industry

There are many lines in the electronic version, waterjet cutting can cut the circuit board of the circuit groove. The process of waterjet cutting will not generate heat, which from the material cutting size has a good control. waterjet cutting machine is a high precision cold cutting, very suitable for application in the electronic products industry.

4. Workshop

Many families have their own maintenance warehouse, you can buy a small waterjet cutting equipment in order to refit and maintain vehicles, or build a favorite car or tools. These all need waterjet cutting equipment to cut, which is very convenient to accomplish flexible production according to their own want graphics.

5: The metal industry

Metal service centers need a cutting method that can cut large areas of material at high speeds. This is why waterjet cutting machine is widely used in industry.

Another advantage of waterjet cutting is that it is perfect for working poorly conductive metals.

6: Pressure test experiment industry

At present, many industries need to carry out pressure test. For example, the fruit juice we study is usually mixed and sterilized in a high-pressure container, which makes the juice taste better, more hygienic and healthy. The pressure range of waterjet cutting equipment is 10MPa-600Mpa, and the pressure of the container can be adjusted according to the needs in the pressure test to find the appropriate pressure.

-

008858-1 DIRECT DRIVE CHECK VALVE ASSEMBLY

008858-1 DIRECT DRIVE CHECK VALVE ASSEMBLY -

A-9228 Seal 1/4″ ID Waterjet Spare Parts

A-9228 Seal 1/4″ ID Waterjet Spare Parts -

044099-1 Ensemble de support de joint à entraînement direct

044099-1 Ensemble de support de joint à entraînement direct -

006765-1 Direct Drive Static Seal; Manifold; .600 ID

006765-1 Direct Drive Static Seal; Manifold; .600 ID -

A-0274-6 Joint torique ; Buna-N ; 90 Duromètre

A-0274-6 Joint torique ; Buna-N ; 90 Duromètre -

A-4691 HP Adapter 9/16″ Male to 3/8″ Female

A-4691 HP Adapter 9/16″ Male to 3/8″ Female -

042218-1 HyPlex Hybrid Maintenance Kit

042218-1 HyPlex Hybrid Maintenance Kit -

013383-1 Corps de clapet anti-retour Eagle 55K

013383-1 Corps de clapet anti-retour Eagle 55K -

042490-1 HyPlex Hybrid End Cap Assembly

042490-1 HyPlex Hybrid End Cap Assembly