Connaissances pour Machine de découpe au jet d’eau abrasif

Maintenance de la machine de découpe au jet d’eau/Découpeuse à jet d’eau CNC

découpe au jet d’eau

The maintenance of cnc water jet cutter includes: nozzle, inspection of oil and filter element of high pressure pump, inspection of high pressure pipeline and joint, inspection of water tank and water pipe, inspection of cutting table, etc. In addition, the nozzle needs to be replaced regularly to ensure cutting quality and service life.

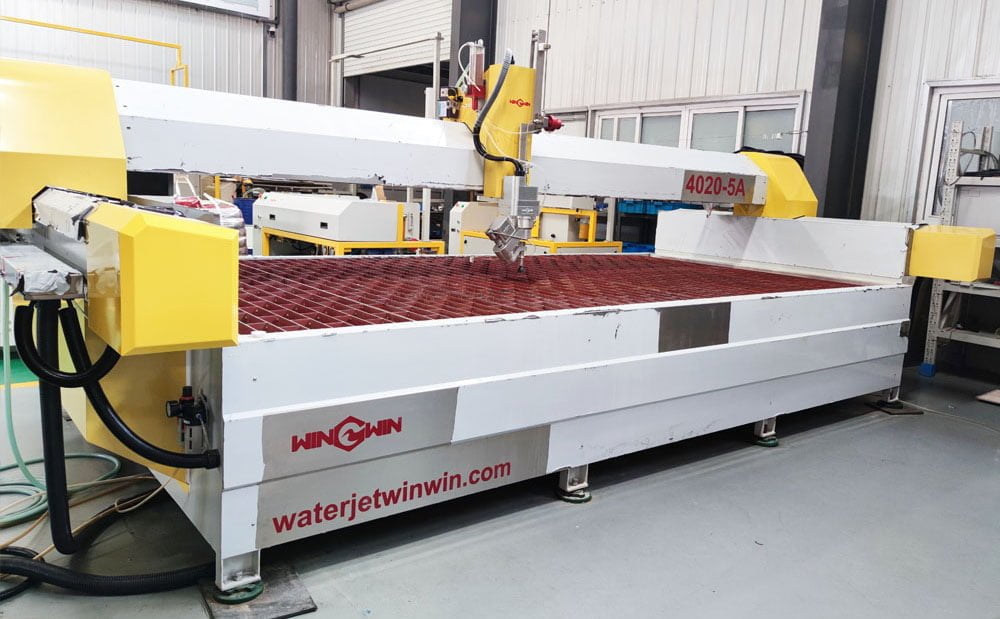

| Série | AC 4020 waterjet | Type | Portique |

| Tête de coupe | Axe AC 5 | Précision du contrôle | ±0,01 mm |

| Angle de coupe | 0-±68° | Course de l’axe Z | 200 mm |

| Précision de coupe | ±0,1 mm | Précision de repositionnement | ±0,05 mm |

| Vitesse de coupe | 11000mm/min | Moteur | 30kw/ 40HP |

| Plage de coupe max. | 2500mmx1500mmx200mm | Certificat | CE/ISO |

Maintenance de la plate-forme de découpe au jet d’eau

According to the data, the maintenance of the waterjet cutting platform includes: cleaning the cutting table regularly, checking the flatness of the cutting table, checking the fixing way of the cutting table, checking the wear resistance of the cutting table, etc. In addition, the cutting table needs to be replaced regularly to ensure cutting quality and service life.

Entretien des Pompe à jet d’eau

According to, the maintenance of waterjet pump includes: regular replacement of oil and filter element, inspection of high pressure pump seals, inspection of pressure gauge of high pressure pump, inspection of cooling system of high pressure pump, inspection of motor of high pressure pump, etc. In addition, the high pressure pump needs to be cleaned regularly to ensure cutting quality and service life.

What consumables does water jet cutting machine need?

According to the water jet cutting machine needs consumables including: nozzle, high pressure pipe, high pressure joint, high pressure pump oil and filter element and so on. In addition, these consumables need to be replaced regularly to ensure cutting quality and service life.

How often are parts of waterjet cutting machines replaced?

According to the paper, the frequency of replacement of water jet cutting machine parts depends on the service frequency and service environment.

Précautions d’entretien de la machine de découpe au jet d’eau

According to the water jet cutting machine maintenance precautions include: before maintenance, need to shut down the high pressure pump and power supply, and empty the high pressure pipeline; During maintenance, professional tools and accessories should be used to avoid damage to the machine; After maintenance, it is necessary to test and debug the machine to ensure its normal operation.

Waterjet cutting machine operation precautions?

According to the instructions, the operation precautions of the water jet cutting machine include: before operation, it is necessary to check whether the high-pressure pump, high-pressure pipeline, nozzle and other components are normal; Wear protective glasses and gloves during operation to avoid injury. After operation, it is necessary to turn off the high pressure pump and power supply, and clean the nozzle and cutting table and other components.

What does the quality of water jet cutting machine parts decide?

According to the results, the quality of waterjet cutting machine parts directly affects the cutting quality and service life. For example, higher quality nozzles can improve cutting accuracy and speed, while lower quality nozzles can lead to lower cutting quality and shorter service life. Therefore, the selection of high quality parts can improve the performance and reliability of the machine.

Are the consumables of water jet machines expensive?

According to this, the price of consumables of waterjet machines depends on such factors as brand, model and quality. Generally speaking, high quality consumables cost more, but can improve cutting accuracy and speed, while extending the service life of the machine. Therefore, the selection of appropriate consumables can improve the performance and reliability of the machine.

How to choose a water jet cutting machine?

Water jet cutting machine is an efficient, accurate and environmentally friendly cutting tool. Waterjet cutting machine can easily cut stainless steel plate or hard marble, granite and so on. It is the ideal or the only processing method for materials difficult to be cut by other methods, such as arylon, titanium alloy and other composite materials. The advantages of water jet cutting include:

1. The cutting direction is not restricted, and all kinds of special-shaped processing can be completed;

2. The lateral force generated by the water jet on the workpiece is very small, which can reduce the setting time and save the use cost of the fixture;

3, water jet cutting will not produce thermal deformation, no secondary processing, can save time and manufacturing costs;

4, water jet cutting speed, high efficiency, low processing cost.

When selecting water jet cutting machine, the following aspects need to be considered:

- Type of cutting material;

- Cutting thickness;

3. Cutting accuracy;

4. Equipment price and maintenance cost.

How to select water jet cutting pump?

Water jet cutting pump is one of the core parts of waterjet cutting machine, it is the high pressure water through the nozzle to form high speed water flow, so as to achieve the cutting of the workpiece. When selecting water jet cutting pump, the following aspects need to be considered: 1. Working pressure; 2. Flow rate; 3, the type of pump; 4. Price and maintenance cost.

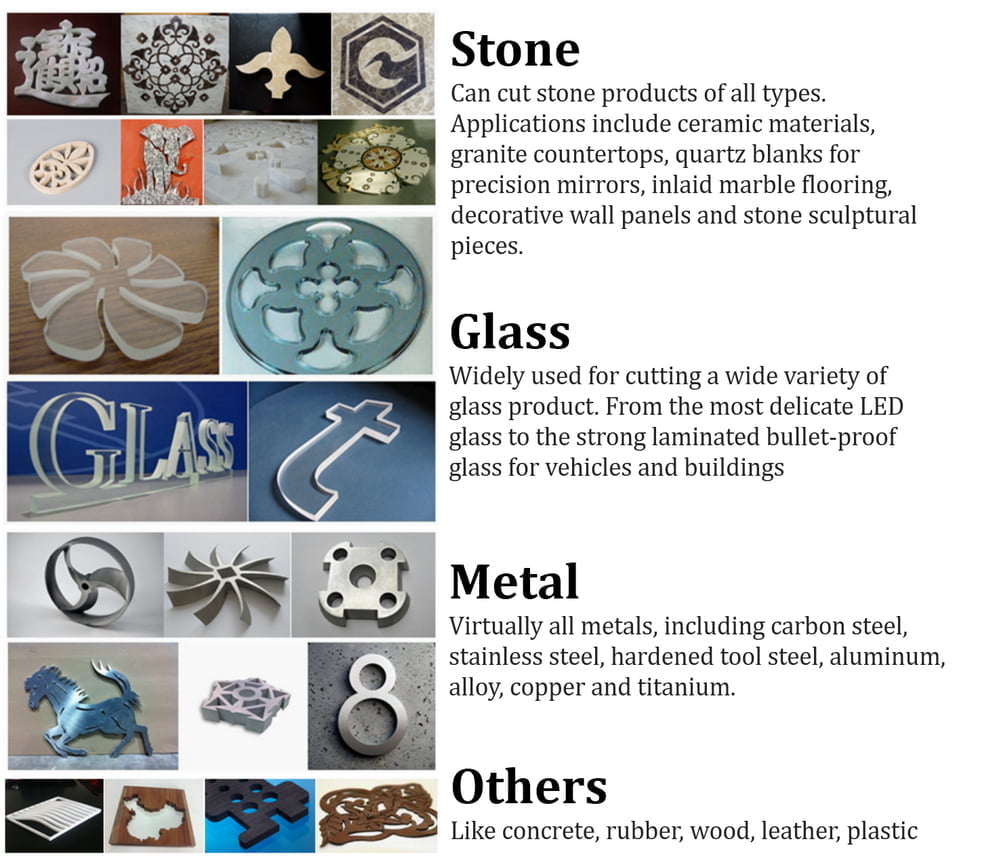

What material cannot be cut by water jet cutting machines?

Waterjet cutting machines can cut most materials, including metal, stone, ceramic, glass, rubber, plastic, etc. However, it cannot cut extremely hard materials such as diamonds and carbide, because these materials are too hard for the water jet cutting machine to cut, and tempered glass, because everything would shatter.

Is waterjet cutting machine widely used?

Waterjet cutting technology is widely used in mechanical equipment manufacturing, stainless steel products, rail transit, pressure vessels, electrical equipment, aerospace, automotive, composite materials, building decoration, stone ceramic processing, glass processing and other fields, and customers in different industries have great differences in the personalized demand for material cutting.

The automobile industry is one of the main application fields of water jet cutting technology, which can process a variety of non-metallic materials, such as instrument panel, blanket, asbestos brake liner, door frame, roof glass, automotive interior decoration board, rubber, plastic gas tank, etc.

Which industries must use waterjet cutting machine production and processing?

Water jet cutting machines are used in many fields, including wood processing, advertising industry, electronics industry, glass industry, paper industry, military industry, etc. The automobile industry also uses water jet cutting technology to process a variety of non-metallic materials, such as instrument panel, blanket, asbestos brake liner, door frame, roof glass, automotive interior decoration board, rubber, plastic gas tank, etc.

What kind of waterjet cutting machine? Win-Win CNC Water Jet Cutter for Sale.

There are many types of water jet cutting machines, mainly divided into large water cutting and small waterjet cutting

1. According to pressure, it is divided into high pressure type and low pressure type, generally with 100MPa as the limit. The high pressure type is above 100MPa, and the low pressure type is below 100MPa. And more than 200MPa for ultra-high pressure type

2. According to the situation in Gaza, water cutting is divided into sand – free cutting and Gaza cutting

3. According to the technical principle, it can be divided into front mixing and back mixing 4. According to the mechanical structure, it is divided into cantilever type and gantry type 5. According to the safety of cutting to be divided into safety cutting class and non-safety cutting class.

About waterjet HP tube/pipe:

High pressure hose is an important part of water jet cutting machine, it can withstand the impact and wear of high pressure water flow, but also can ensure the stability of water flow and flow.

What is the function of the cutting head of the water jet cutting machine?

The cutting head of the water jet cutting machine is one of the core parts of the water jet cutting machine. It is the part that ejects the high-pressure water flow and abrasive after mixing, and plays the role of ejects the high-pressure water flow and abrasive after mixing. The purpose of the cutting head is to spray a mixture of high pressure water and abrasive material so that it can form a small hole in the surface of the workpiece, and then by constantly moving the cutting head so that it forms a complete cut in the surface of the workpiece.

There are many types of water jet pump, common plunger type water jet booster pump, film type water jet booster pump, screw type water jet booster pump and so on.

Type de table de découpe au jet d’eau machines de découpe au jet d’eau

There are two main types of water jet cutting platform, which are water-only cutting technology and abrasive water cutting technology. Before choosing one type, it is necessary to have a full understanding of both types.

Type de plate-forme de découpe au jet d’eau abrasif

Abrasive water jet cutting is a technology that uses high speed rotating abrasive particles to grind workpiece surface to achieve cutting purpose. This technique can be used to cut a variety of materials, such as metals, ceramics, glass, plastics, etc.

Structure de la table de découpe au jet d’eau abrasive

The structure of abrasive water jet cutting platform is generally divided into three parts: waterway system, sand road system and action actuator. The waterway system is mainly composed of high pressure water pump, high pressure pipeline, high pressure valve, water cutting and so on. The sand road system is mainly composed of sand box, sand conveying pipeline, sand control valve and so on. The action actuator is mainly composed of X, Y, Z three-axis servo motor, reducer, guide rail and so on.

What are the drainage ways of water jet cutting table?

There are two drainage methods of water jet cutting platform: one is direct discharge, that is, direct discharge of waste water into the sewage pipe; The other is recycling, where waste water is collected, treated and reused

Procédé d’élimination abrasive de la table de découpe au jet d’eau

The desanding methods of water jet cutting platform are generally divided into two kinds: one is gravity desanding, that is, the Abrasive is separated out by gravity; The other is centrifugal Abrasive removal, which separates the Abrasive material by centrifugal force.

What are the cooling modes of water jet cutting machine?

There are generally two cooling ways of water jet cutting machine: one is air cooling, that is, the heat is sent out by the fan;

The other is water cooling, which removes heat through the water cycle.

There is also a more advanced and efficient form of refrigeration: the refrigerator industrial refrigerator refrigeration.

What are the types of oil pumps for water jet cutting machines?

The oil pump of the water jet cutting machine is generally divided into two types: one is the plunger type oil pump, that is, the oil is compressed by the plunger; The other is the gear pump, that is, through the gear to compress the oil.

What is the function of the discharge valve of the water jet cutting machine?

The discharge valve of water jet cutting machine is used to limit the flow of fluid and to regulate the pressure.

What are the types of water jet cutting machine abrasive tank and what are their advantages?

There are many types of water jet cutting machine for abrasive tank, such as: automatic abrasive supply system, water jet cutting automatic sand tank feeding device.

The automatic abrasive supply system provides high efficiency, safety, convenience and simplicity for the water cutting machine. When cutting hard materials, hard garnet sand is usually mixed in a high pressure water jet to make the cut.

The water jet cutting automatic abrasive feeding device includes supporting beam, cylinder, sand guide groove, etc., which can realize automatic abrasive supply and improve working efficiency.

How to choose abrasive garnet for water jet cutting machine?

Water jet cutting abrasive mainly emery, olivine, garnet, copper smelting furnace slag and oxide. Among them, 80-100 purpose garnet is the most commonly used. You can choose the appropriate particle size and type of abrasive according to your requirements.

La structure de la table de découpe au jet d’eau

The structure of water jet cutting table generally includes high pressure pump, control system, cutting head, cutting table and other parts. Among them, the high pressure pump is the core component of water jet cutting, the control system is the brain of the whole equipment, the cutting head is the key component that converts the high pressure water flow into the cutting ability, and the cutting table is the platform where the cut objects are placed. It may vary by make and model, but it is generally made up of these components.