Do you want to have an intensifier pump with good looks and high cost performance?

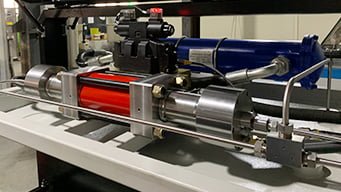

The intensifier pump of WW40JET is a very good pump, its maximum pressure is 60,000psi/420mpa/4200bar, and the continuous working pressure is 320-360mpa.

The following is a case of our machine, from which we can see that it is very popular with users:

An American customer purchased a set of our robotic water jet cutting workstation, you can see from the picture that this abrasive robotic water jet cutting workstation is matched with our WW40JET water jet pump, the customer uses this set of equipment to cut military protective helmets, Due to the hardness and thickness of the helmet, this is an abrasive water jet cutting system. From the picture, we can see that this is a fully enclosed house-style robot equipment and is equipped with a peeping rolling door design and infrared rays. Inductive, the above devices can effectively protect the safety of cutting workers. This set of equipment is equipped with an ABB ceiling type robot. Under the robot is a cutting platform specially designed and built for customers. It can place four helmets at a time, effectively saving the cutting operation time.

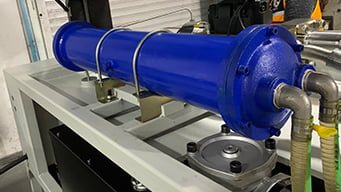

And this set of equipment is also matched with our special cooling system, which is a professional refrigerator specially developed and manufactured by us for the water jet cutting system. The cooling effect is very good, which can effectively ensure the stable operation of the machine for a long time.

Of course, our 40JET water jet pump can also be matched with water jet cutting machine, portable water jet cutting equipment, or used to replace old water jet pumps, etc. It is a very versatile product.

Performance and advantages of the WW40JET pump:

- The appearance is novel and bright, and the transparent upper cover design is fashionable and very user-friendly, allowing the operator to see the working status of the intensifier at any time and conveniently

The operation buttons are concentrated and clearly marked, and the height is appropriate, which is very convenient for the operator to use - High Performance and Standard Design:Universal Structure Design, International Standard Spare Parts. High versatility of accessories, customers can purchase the corresponding parts in any waterjet machine market.

- Reliable Protection System:The automatic protection system shutdown when water shortage or overheating, could working continuously and safely.

- Newly designed accumulator:Newly designed accumulator, integral forging, no rubber seals, maintenance-free.

- Double Oil-Filtration System:Double filtration devices are set at the oil inlet and oil return port to ensure the oil path is clean, smooth and not blocked, and prolong the service life of the Intensifier Pump.

So what industries is this 40JET intensifier suitable for?

1. Various metal cutting: stainless steel, steel, iron, cast iron, carbon steel, alloy metal, titanium aluminum alloy, aluminum, copper, etc.

2. Glass cutting: ordinary glass, laminated glass, plexiglass, windshield of automobiles, boats and other vehicles, etc., but tempered glass cannot be cut.

3. Stone industry: marble, stone, granite, ceramic tile, ceramics, etc.

4. Other materials: rubber, plastic, ingredients (cake, chocolate, frozen meat, etc.).

Of course, it is not limited to the above industries and materials. The water jet machine can be said to be a universal cutting machine, and it is very environmentally friendly, will not produce dust pollution, and has no thermal effect, and will not damage the cutting material.