La structure du portique assure la stabilité de la machine-outil et la structure réglable peut assurer la précision de coupe

La structure immergée dans l’huile, le curseur à vis est trempé en permanence dans l’huile lubrifiante, ce qui réduit considérablement l’usure du curseur à vis, et la durée de vie est aussi longue que dix ans

Poutres en fonte et profilés en alliage d’aluminium, structure déstressée, haute résistance, légèreté, facilitant le fonctionnement de la machine-outil

Les composants électriques utilisent les marques Omron et Schneider

Fournir une limite souple fiable pour les machines-outils, sûre et sécurisée

Poignée de télécommande sans fil, pratique et rapide

Conception étanche à la poussière en acier inoxydable, pas de rouille, pas de pourriture

Beautiful appearance, reasonable structural design, good rigidity and stability, stable high-speed operation, precision control at 0.01mm,

The X-axis adopts Taiwan TBI linear guide rail or ABBA lead screw slider to ensure the accuracy of the transmission. Durable and high-quality is the goal of Win-Win.

High-quality three-proof drag chain, fireproof, antifreeze, antiaging, good durability, the cable is a special cable, good flexibility, high reliability

Over-travel automatic limit function, combined with the sensor limit module, double limit allows the operator to operate with confidence

The Z-axis uses double guide rails with sliders and a screw structure to ensure strength, precision and good practicability

Finished machine base, internal and external reinforcement structure, parallel seat stress relief design, permanent invariance

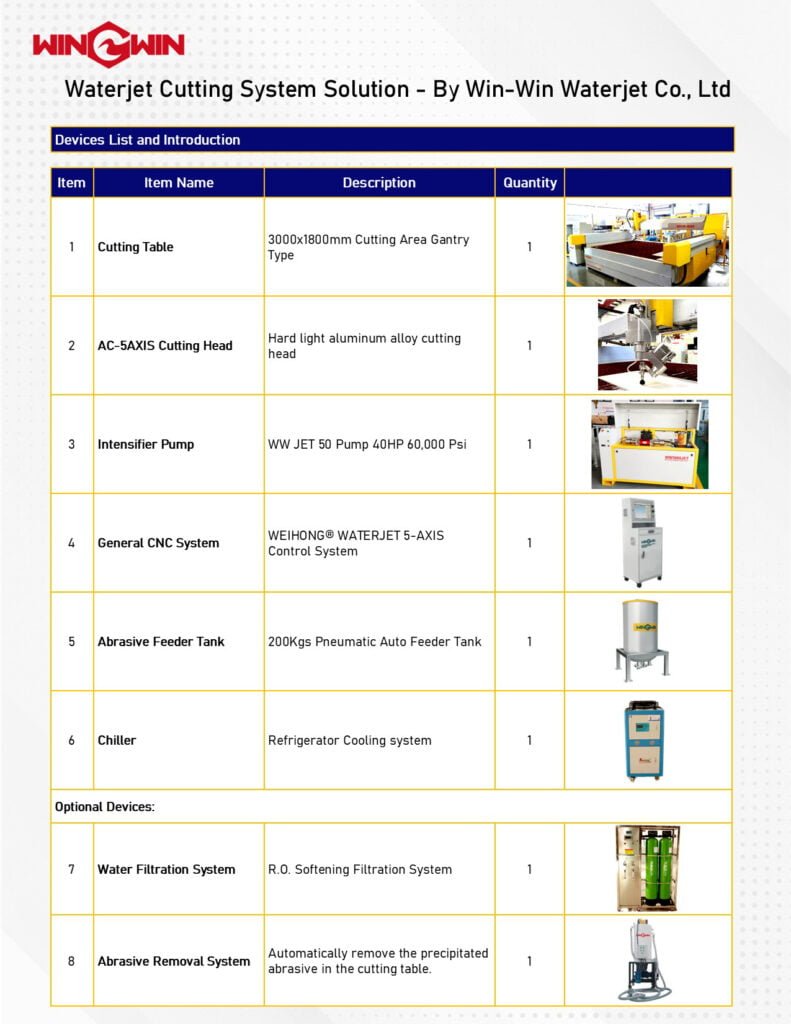

AC five-axis CNC high-pressure waterjet cutting system:

The five-axis and five-linkage system of the ultra-high pressure waterjet cutting machine can realize the rotation of the cutter head in any direction, realize the cutting bevel at any angle, and solve the slope defect caused by the water cutting drift.

Application fields: mechanical processing, stone processing, aerospace, military production, automobile manufacturing, architectural decoration.

With optimized structural design, small size and light weight, it can be installed on existing cantilever and gantry waterjet cutting machines.

Its maximum inclination angle is 0-75°, and the bevel angle is automatically adjusted through the CNC control system, which is convenient and reliable. Users can conveniently set the required tilt angle. Reach the vertical cutting plane;

The AC axis adopts a harmonic reducer, which has the characteristics of high positioning accuracy and small backlash

This product is especially suitable for marble processing in the decoration and tile mosaic industry, which saves the cumbersome process of secondary polishing. The speed and quality of processing are improved, and the verticality of the incision is also improved in the cutting fields of glass, metal, and composite materials.

This equipment is used by customers for rock slab cutting. The AC five-axis waterjet cutter recommended by WIN-WIN can easily solve the 45° large-angle cutting demand for rock slabs, and at the same time meet the needs of small-angle tile mosaic. One machine with multiple functions realizes the value of artistic creation.

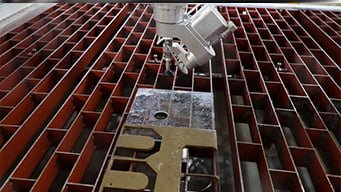

Optional intensifier pump WW60JET features:

Mode de liaison à double intensificateur, durée de vie plus longue, intervalle de maintenance plus long, deux fois plus long que les pompes intensificatrices ordinaires

Larger flow, can drive nozzles with 0.38mm hole diameter, faster cutting speed

En utilisant un accumulateur de grande capacité de 2L, la pression est stable, ce qui résout efficacement le phénomène de coupe imperméable dû à une pression instable.

Low pressure start, zero pressure wait, high pressure operation, this is a new mode, start to start low pressure mode, effectively reduce the motor load, during the cutting process, the machine tool idle time, intensifier pump high pressure water maintains 60,000psi high pressure. The oil pressure is in a low-pressure state, which is effectively protected and sealed. When cutting is required, high-pressure cutting is enabled. This technology is very suitable for water jet cutting intensifier pumps.

Double oil filtration system to ensure the quality of hydraulic oil, a box of hydraulic oil can be used for more than five years

Trois systèmes de filtration de l’eau pour assurer la qualité de l’eau et prolonger la durée de vie des pièces

Using a 60HP motor, the power of the motor has been scientifically calculated, just right, and will not cause waste in the store

Structure de cadre modulaire pour un remplacement facile des pièces

The top transparent acrylic cover is used, which is beautiful and can always observe the internal situation of the booster pump

Le panneau de commande dispose d’un voyant d’alarme. Lorsque les conditions externes ne peuvent pas répondre à la norme de démarrage, le voyant lumineux s’allume régulièrement, ce qui est pratique pour trouver la cause et la résoudre rapidement.

Imported high-pressure pipeline, shockproof, high pressure resistance, longer service life

The core parts of the booster pump are produced in the United States to ensure the quality of the machine tool

The highest pressure can reach 4200bar, with 0.38mm aperture stone, it can realize fast cutting and ultra-thick material cutting

The optional mode has two supercharger linkage modes and a single operation mode, and the single operation mode can ensure uninterrupted work