Description

Waterjet Spare Parts Waterjet Direct Drive Pump Parts A-26490-1 Pony Rod for Hyplex Prime

Questions and answers about waterjet cutting machines and Waterjet spare parts from waterjet cutting users.

Q1, What is your smallest entry level waterjet machine? This would be our own evaluation / test and training machine. What would be pricing for that?

A1, Generally speaking, the smallest machine we currently sell is a 2000*1500mm cutting table, can be matched with 3-axis or 5-axis cutting heads and systems.

Generally speaking, as an intermediary customer, many will purchase a water jet cutting machine with standard configuration from Win-Win at the very beginning to show the configuration, performance and cutting effect of the machine to local customers, and to The operation and use of the machine, in order to sell water jet cutting equipment.

So what devices does this machine with Win-Win standard configuration contain?

1.1 Waterjet cutting table, its effective cutting area size is 2000mm*1500mm, our lead screw and slider adopt a new, oil-immersed structure, which can ensure smoother operation, and the diameter of the lead screw is thicker, so as to Ensure that the platform runs more stably. In addition, the sink shell of our cutting platform is made of all stainless steel, so that the machine can be as new as 10 years without being corroded and rusted. And we canceled the dust-proof folding cloth, and adopted an integrated stainless steel protection, so that the dust-proof and waterproof effect of this machine is better, and the internal parts are not damaged.

1.2 Waterjet cutting head, this item needs to be selected according to the cutting material and cutting requirements of the user. If the user needs to cut glass and metal, generally speaking, 3-axis (vertical cutting) is enough; if the user needs to cut tiles, marble, granite For materials that require angle compensation, you need to choose AC-5axis, because the angle that this cutting head can achieve is 0-68 degrees, which can meet the needs of tile mosaic and marble splicing.

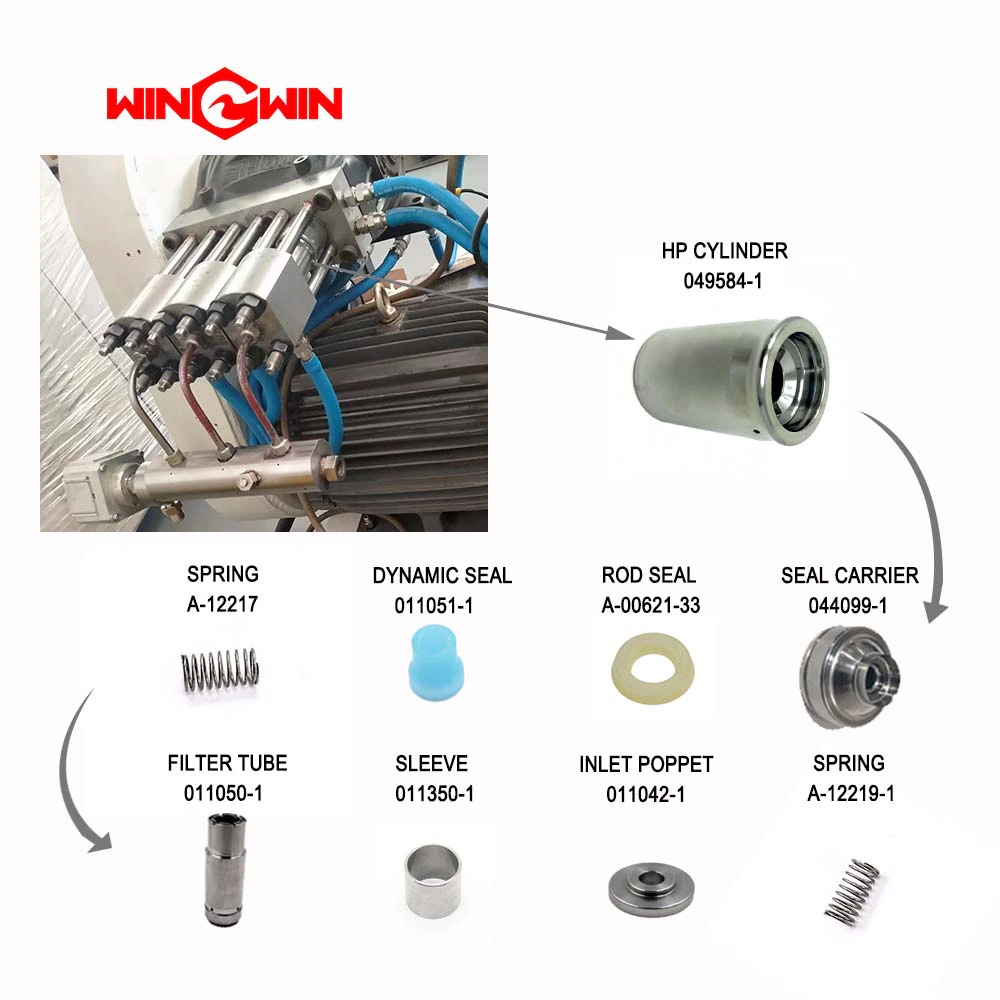

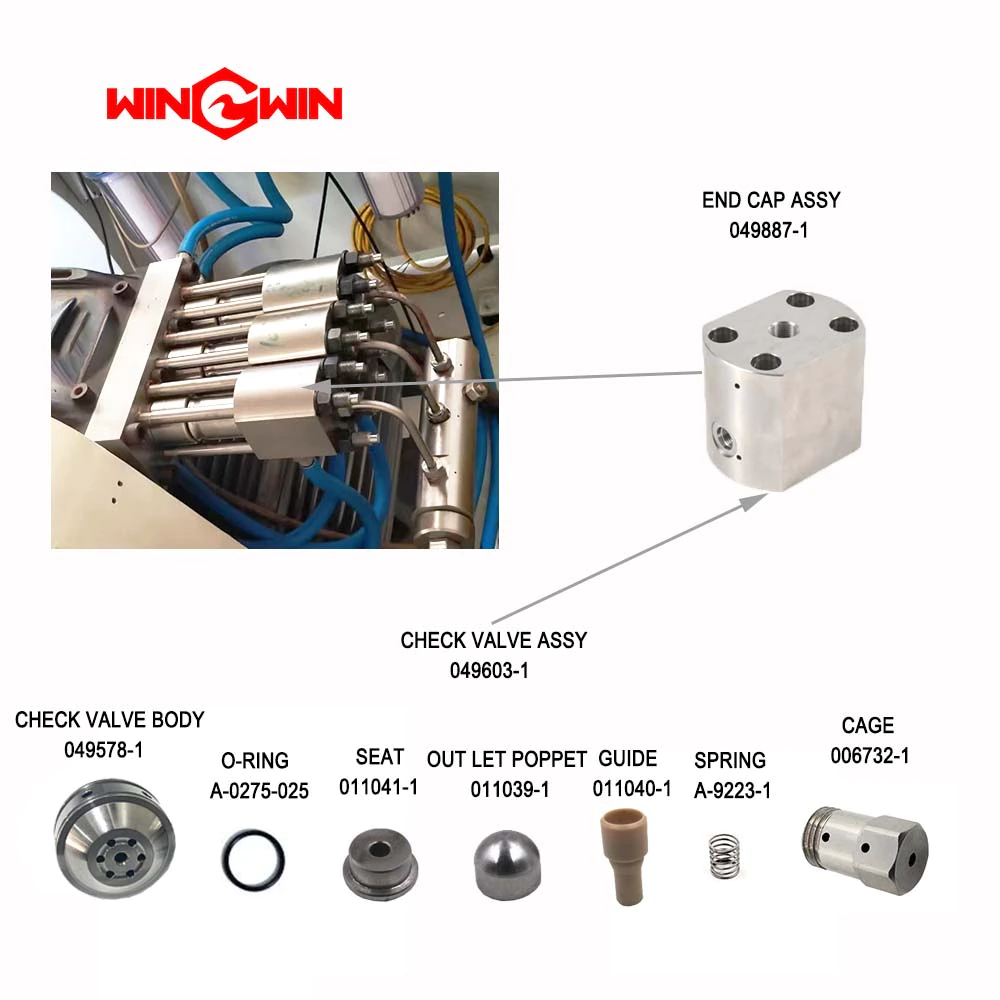

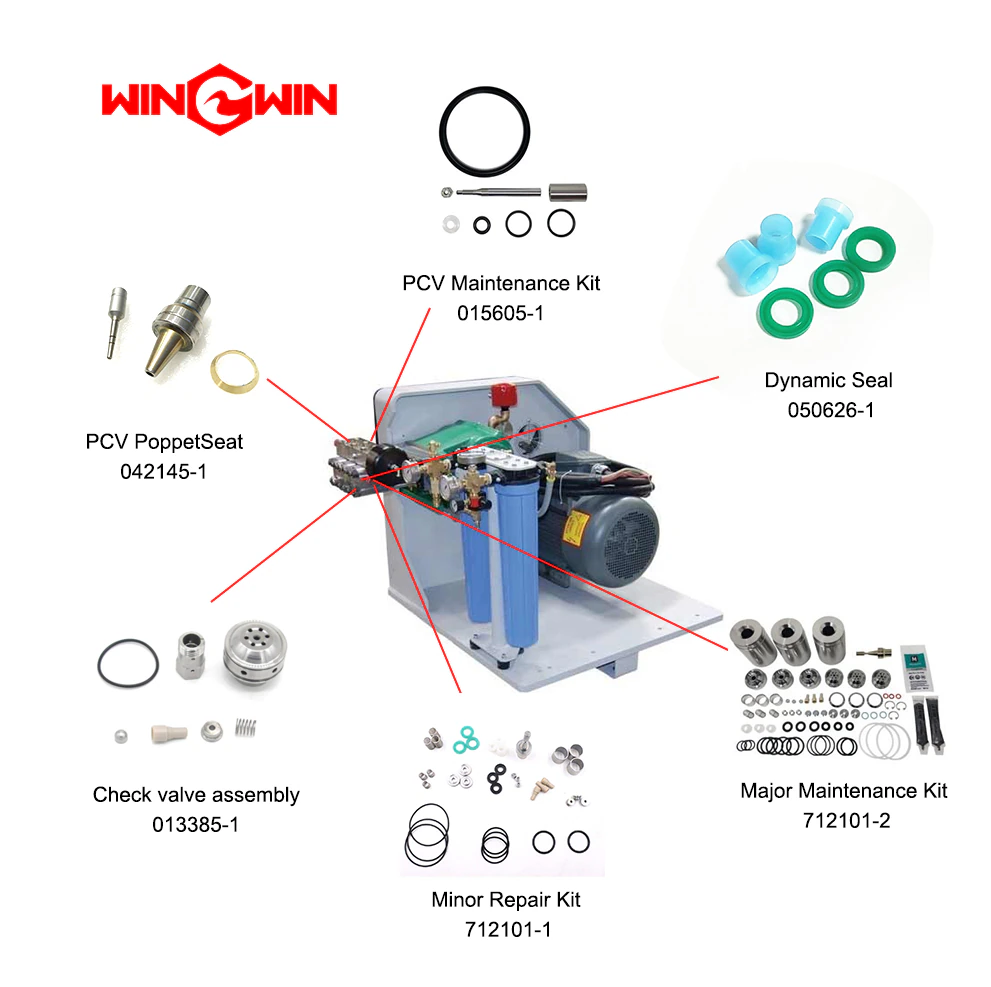

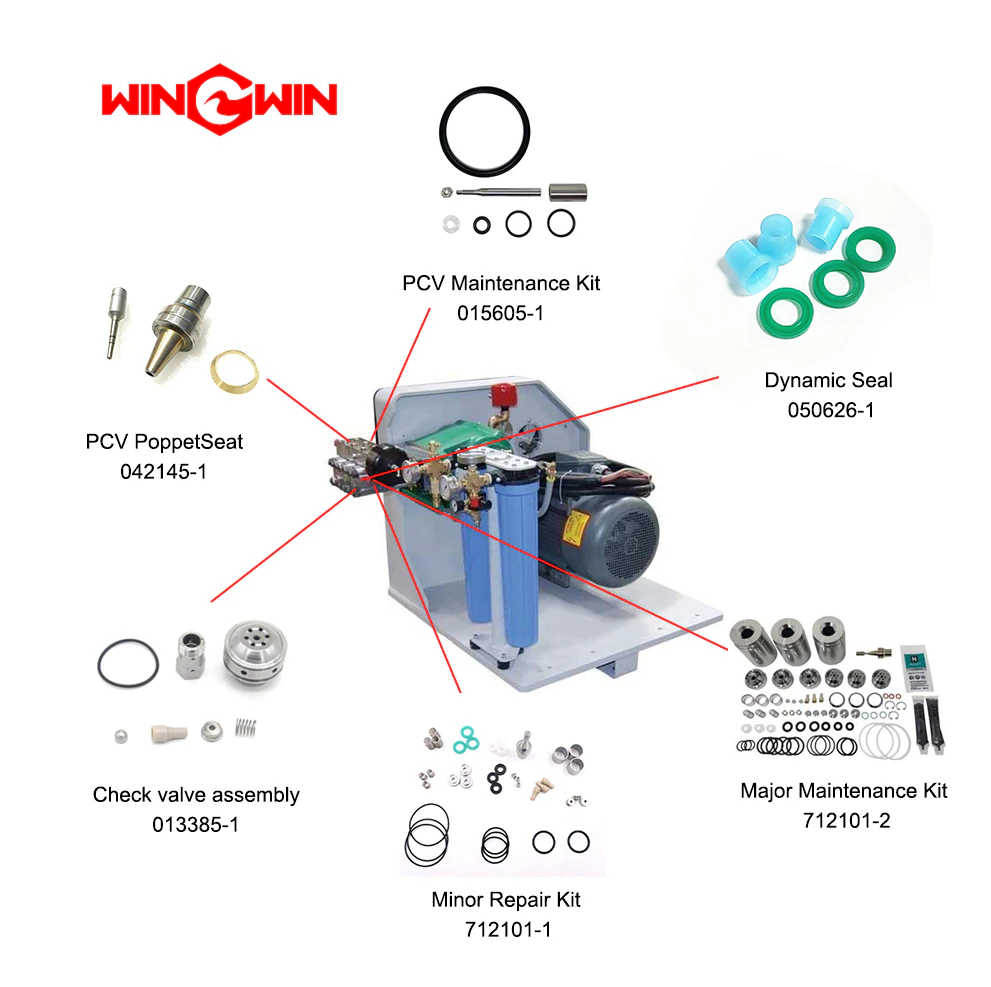

1.3 Waterjet high pressure intensifier pump, usually we can choose WW5060JET intensifier pump, the maximum pressure of this intensifier pump is 420mpa/60,000psi, it matches the international general intensifier.

1.4 WEIHONG CNC control system, which is an operating software of an internationally renowned brand, has strong versatility, simple operation and stable operation.

1.5 Chiller, this is an industrial chiller specially designed and improved by Win-Win for water jet cutting machines. The cooling effect is very good, which can ensure the stable operation of the machine for a long time.

1.6 Abrasive feeder tank, we use thickened material to make it, explosion-proof and corrosion-proof, strong and durable.

1.7 For customers who purchase waterjet cutting machine, we will give away 250kg of abrasives and some commonly used waterjet spare parts.