Description

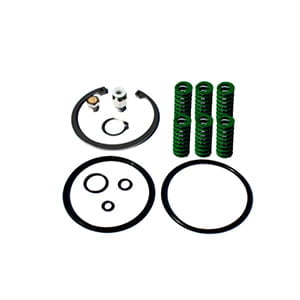

500-20-0110 HP Outlet Poppet Kit – Seat, Poppet & Spring Waterjet Replacement Parts

The 500-20-0110 HP Outlet Poppet Kit includes:

500-20-0112 HP Spring

500-20-0111 HP Check Valve Seat

500-20-0113 HP Outlet Poppet

| IMAGE | SKU | NOM | ||

|---|---|---|---|---|

| 500-20-0059 | Diamond Orifice 0.013″ | |||

| 500-20-0060 | Diamond Orifice 0.014″ | |||

| 5116561 | Discharge Poppet Check Valve | |||

| 05116561 | Discharge Poppet Check Valve | |||

| 12401 | Élément filtrant | |||

| 10126969 | Focusing Tube 0.030″ | |||

| 500-15-0060 | Focusing Tube 0.030″ (3″) Straight cutting | |||

| 10126928 | Focusing Tube 0.040″ | |||

| 500-15-0070 | Focusing Tube 0.040″ (3″) Straight cutting | |||

| 500-15-0020 | Focusing Tube 0.040″ (PAC – 2.5″) | |||

| 11679-012 | Garnet Tube O-Ring | |||

| 500-3-0061 | Grease, 0.75 OZ | |||

| SP1115 | Guide Bush Assembly | |||

| SP1092 | Guide Bush Assembly 55K | |||

| SP1107 | Guide Bush Assembly 66K | |||

| SP1120 | Guide Bush Assembly 66K | |||

| 10079580 | HP Adaptor (For Square Valve Body Only) | |||

| 500-20-0111 | HP Check Valve Seat | |||

| 11288 | HP Coned Insert | |||

| 500-20-0113 | HP Outlet Poppet | |||

| 500-20-0110 | HP Outlet Poppet Kit – Seat, Poppet & Spring | |||

| SP1052 | HP Seal Assy 66K | |||

| SP1055 | HP Seal Assy 66K | |||

| SP1060 | HP Seal Assy 66K | |||

| 500-20-0112 | HP Spring |

Knowledge of Waterjet Cutting Machine and Waterjet Parts Waterjet Replacement Parts:

There are many Waterjet Replacement Parts seals in the water jet cutting machine, and these Waterjet Replacement Parts seals are also very important. If the seals are aging, worn, loose or cracked, it will affect the operation and cutting efficiency of the water jet cutting machine.

Here are some common problems and solutions for waterjet cutting machine seals:

1. Leakage caused by aging or wear of seals: The Waterjet Replacement Parts seals in water jet cutting machines are divided into three categories, oil seals, water seals, and air source seals. Once the machine leaks, we must first consider It is whether there are seals in these positions, whether it is due to the aging or wear of the seals, we need to disassemble them for identification, and then carry out maintenance. Usually rubber seals cannot be repaired and need to be replaced. But if it is a hard seal, that is, a metal seal, you can check the situation to see if it can be repaired or replaced.

2. The water pressure is too high or too low: the pressure of the water jet cutting machine has a specified value. If it exceeds the limit value, it is very easy to cause the damage and failure of each seal. Therefore, be sure to adjust and use the machine within the specified range.

3. Improper installation: We know that many seals of water jet cutting machines are composed of two, three, or even four or five sets, and the installation order of these seals is very important. Once the installation is wrong, it will Lead to failure or damage, or even affect the use of other components, so it is necessary to learn and follow the normal operation tutorial to install and replace.

4. Improper cleaning of the machine: If the parts, the relevant installation positions and the hands of the operator are not thoroughly cleaned when installing and replacing the seals, impurities may be mixed into the parts and equipment, resulting in damage to the machine or parts.

In summary, we need to pay attention to the above details.

Win-Win is a waterjet cutting machine Waterjet Replacement Parts and Waterjet Parts manufacturer, If you want to know anything, Contactez-moi s’il vous plaît

The following is our products and Waterjet Replacement Parts display.

Win-Win provice Waterjet Replacement Parts nozzle, Waterjet Replacement Parts orifice, Waterjet Replacement Parts cutting head parts, Waterjet Replacement Parts pump parts and other Waterjet Replacement Parts.