Description

Waterjet repair the High Pressure Fittings

Usage: Normally, a waterjet intensifier has many high pressure fittings with different dimension.

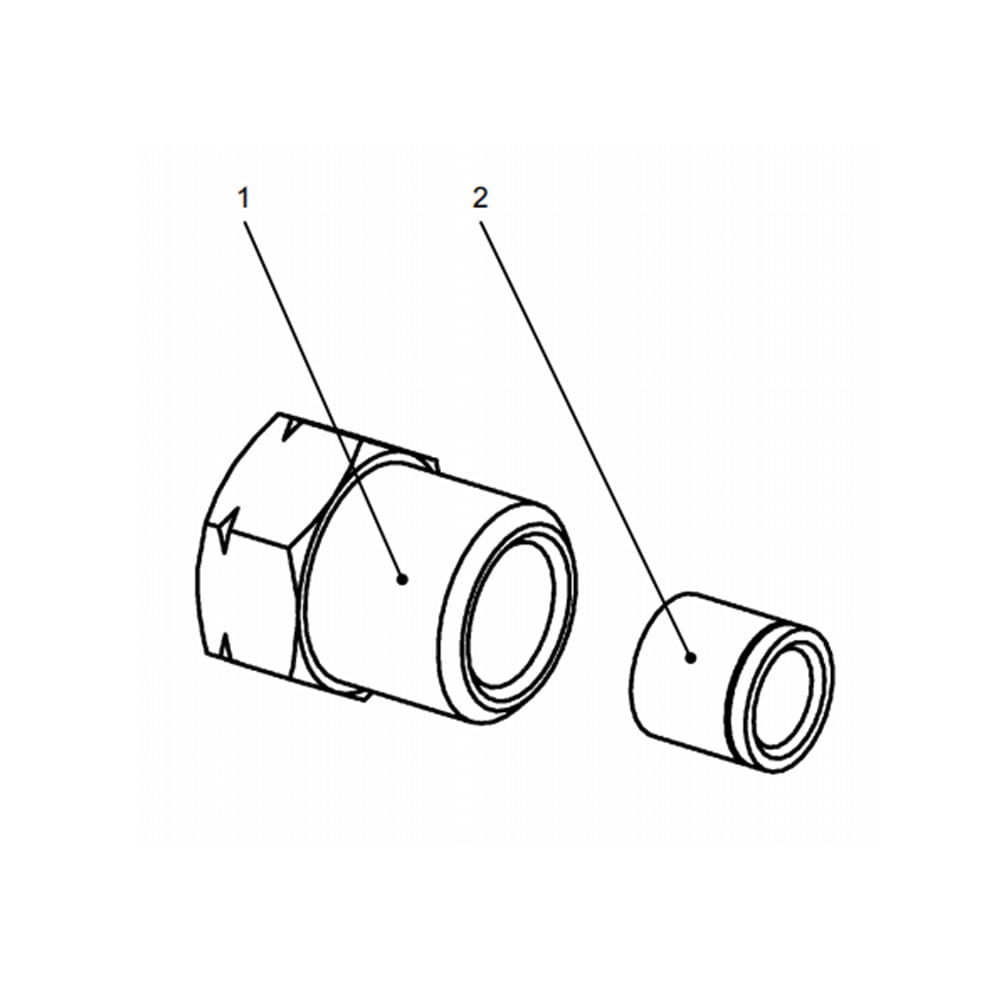

Related waterjet repair of the high pressure fittings:

| Numéro d’article | Specification | Description |

| 1000878 | 6mm | Glande |

| 1001568 | 10mm | |

| 1000701 | 14mm | |

| 1000971 | 6mm | Collar |

| 1001567 | 10mm | |

| 1000702 | 14mm |

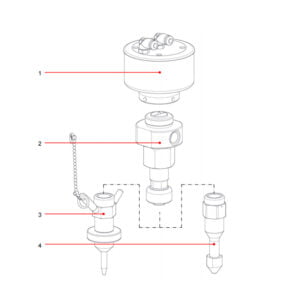

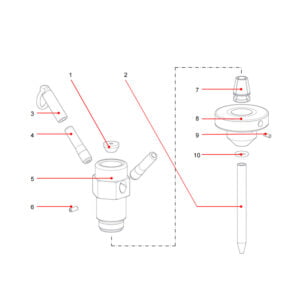

Ohter related waterjet cutting parts:

| 1027347 | Corps de soupape |

| 1004604 | Ensemble clapet anti-retour |

| 1003551 | Piston hydraulique |

| 1003544 | Vérin hydraulique |

| 1003644 | Boîtier du filtre |

| 1003433 | Adaptateur de clapet anti-retour |

| 1004146 | Vérin hydraulique |

| 1001653 | Bague d’étanchéité haute pression |

| 1009700 | Couplage |

| 1003302 | Filtre haute pression |

| 1004541 | Kit de réparation de clapet anti-retour |

| 1004386 | Bague de retenue du piston |

FAQ of waterjet cutting machine & waterjet repair:

- What materials are waterjet high pressure fittings made of? Waterjet high pressure fittings are typically made of durable materials that can withstand high pressure and resist corrosion, such as stainless steel, brass, or titanium.

- How do I choose the right waterjet high pressure fittings for my system? The choice of waterjet high pressure fittings will depend on factors such as the operating pressure of the system, the size and type of hoses and tubes, and the specific requirements of the application. It is important to choose fittings that are compatible with the rest of the system and can handle the required pressure.

- How do I install waterjet high pressure fittings? Installation procedures will vary depending on the type of fitting and the specific system requirements. It is important to follow the manufacturer’s instructions and use appropriate tools and techniques to ensure a secure and leak-free installation.