Description

Pièces de pompe à jet d’eau Kit de réparation de clapet anti-retour

Numéro d’article : 1004541

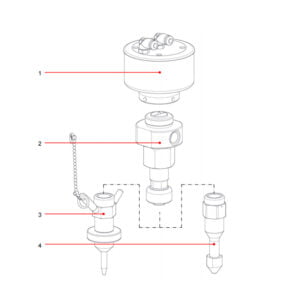

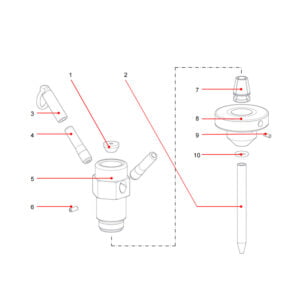

| 1027347 | Corps de soupape |

| 1004604 | Ensemble clapet anti-retour |

| 1003551 | Piston hydraulique |

| 1003544 | Vérin hydraulique |

| 1003644 | Boîtier du filtre |

| 1003433 | Adaptateur de clapet anti-retour |

| 1004146 | Vérin hydraulique |

| 1001653 | Bague d’étanchéité haute pression |

| 1009700 | Couplage |

| 1003302 | Filtre haute pression |

| 1004541 | Kit de réparation de clapet anti-retour |

| 1004386 | Bague de retenue du piston |

FAQ of waterjet cutting machine & waterjet accessories:

- Combien coûte le jet d’eau ?

- Quelle est l’avance maximale de la machine ?

La vitesse d’avance d’une machine de découpe au jet d’eau peut varier considérablement en fonction de plusieurs facteurs, tels que le matériau à couper, l’épaisseur du matériau, la pression et le débit du jet d’eau et le diamètre de la buse de coupe. En général, la vitesse d’avance d’une machine de découpe au jet d’eau peut varier de quelques centimètres par minute (IPM) à plusieurs centaines d’IPM. Par exemple, la coupe à travers de l’acier épais peut nécessiter une vitesse d’avance plus lente, tandis que la coupe à travers de l’aluminium mince peut permettre une vitesse d’avance plus rapide. Il est important de noter que la vitesse d’avance d’une machine de découpe au jet d’eau doit être optimisée pour chaque travail de coupe spécifique afin d’obtenir les meilleurs résultats en termes de vitesse et de précision de coupe, tout en minimisant le gaspillage de matériaux et l’usure de la machine. Normalement, l’alimentation en grenat est d’environ 5 à 30 kg par heure de la machine de découpe au jet d’eau abrasif.

La fonction du clapet anti-retour des pièces de pompe à jet d’eau dans un système hydraulique est de permettre au fluide de s’écouler dans une seule direction. Il s’agit d’un type de vanne qui permet au fluide de s’écouler dans une direction, tout en empêchant le reflux dans la direction opposée.

Dans un système hydraulique, les clapets anti-retour sont généralement utilisés pour empêcher le fluide de refluer dans la pompe ou d’autres composants du système lorsque la pression chute ou que la pompe est éteinte. Cela permet de maintenir la pression du système et d’éviter d’endommager les composants du système.

Les clapets anti-retour peuvent également être utilisés pour isoler différentes sections d’un système hydraulique, empêchant ainsi le fluide de s’écouler entre elles. Cela peut être utile pour contrôler le flux de fluide vers différentes parties d’une machine ou d’un système.

Dans l’ensemble, les clapets anti-retour jouent un rôle important dans le maintien du bon fonctionnement et de la sécurité des systèmes hydrauliques, en veillant à ce que le fluide s’écoule dans la direction prévue et en prévenant les dommages ou les dysfonctionnements dus au refoulement.