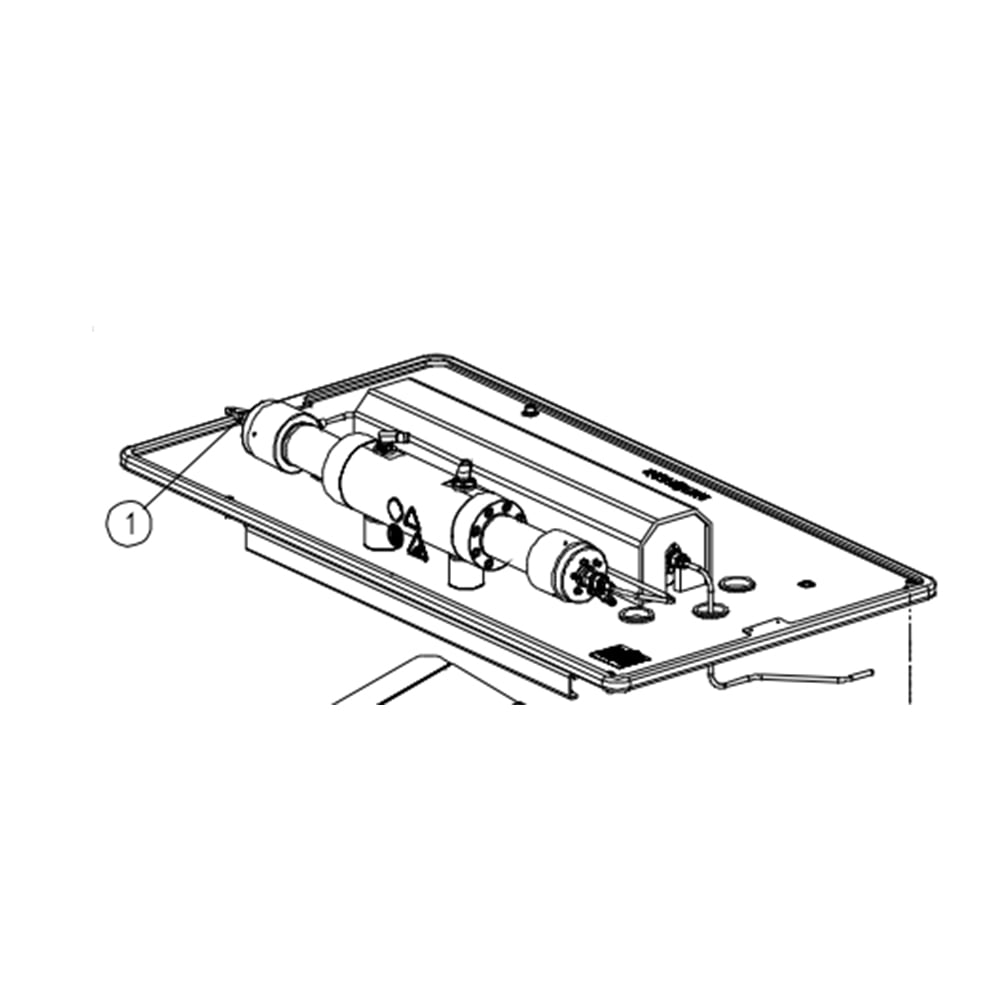

Description

Waterjet parts: High pressure piping

Item number: 20429831

Details: used on the sl-vi 100hp waterjet cutting machine

Related waterjet parts:

| Numéro d’article | Description |

| 72119536 | pièces jet d’eau Cylindre HP |

| 05144506 | pièces jet d’eau Piston en céramique |

| 20416445 | pièces jet d’eau Culasse hydraulique |

| 72110979 | pièces jet d’eau Ensemble de tête d’étanchéité |

| 05149711 | waterjet part HP seal assembly |

| 49838220 | waterjet part Écrou de cylindre HP |

FAQ of platform waterjet machine etc.:

How do water jets cut metal?

Waterjet machines cut metal, it is difficult to cut through with pure water, and the cutting speed will be very slow. To cut metal, a fluid mixture of water and abrasives must be used for cutting. The process involves the following steps: Pressurization: Water is pressurized to very high levels, typically between 30,000 and 90,000 psi (pounds per square inch), using a pump. Mixing: The pressurized water is then mixed with abrasive particles such as garnet, which can help increase its cutting power. The abrasive particles are added to the stream of water using a mixing chamber. Nozzle: The high-pressure water and abrasive mixture is then forced through a small nozzle, which can be made from materials such as tungsten carbide or sapphire. The nozzle is designed to focus the stream of water into a thin, high-velocity jet that can cut through the metal. Cutting: When the water jet stream makes contact with the metal, it rapidly erodes the material, creating a cut. The high-pressure water and abrasive particles can cut through a range of metals, including steel, aluminum, copper, and titanium. Water jet cutting has several advantages over other cutting methods, such as laser or plasma cutting. It produces less heat, which can help prevent warping or distortion of the metal, and it can cut through thicker materials. Additionally, water jet cutting does not produce harmful fumes or gases, making it a safer and more environmentally friendly cutting option.