Description

If you want to get the waterjet orifice or waterjet mixing tube product catalog or the price list, please Contactez-nous.

Waterjet Orifice Standard Size: 0.005″~0.018″

Generally speaking, there are two types of waterjet orifice that we commonly use. One is the orifice used for pure waterjet cutting. The aperture of this orifice is relatively small. The most commonly used apertures are orifice with apertures of 0.17mm and 0.18mm; The other is the orifice used for abrasive waterjet cutting. The aperture of this orifice is relatively larger, and the commonly used sizes are 0.25mm, 0.26mm, 0.30mm, 0.33mm etc. Generally speaking, the larger the aperture, the more water column Larger, the cutting speed is relatively fast, but the accuracy is relatively poor. On the contrary, the smaller the aperture, the slower the cutting speed and the higher the cutting accuracy, but the relative wear of the orifice may be greater, so I think To choose a waterjet orifice suitable for your working conditions, it is best to consult waterjet-related professionals for better professional advice, you can also contact us, we provide free technical support !!!

Related Waterjet Orifice with item numbers for your reference:

| Description | Numéro d’article |

| ECL style | 014155-xx |

| 014201-xx | |

| Water-only | 003788-xx |

| D-5071-x | |

| 004519-xx | |

| Instajet style | 001821-xx |

| P4 | 015849-xx |

| 041759-xx |

| Description | Numéro d’article |

| Water-only | A2260005 |

| 05133848 | |

| 20431118 | |

| 49863680, 49863616, 49865850 | |

| Ruby | 05109079, 05109095 |

| 05109103, 05109111, 05109137 | |

| 20448541 | |

| 05114913 | |

| Diamant | 05112537 |

| 05077029, 05077037, 05077300 | |

| 05101753 | |

| 05136098 |

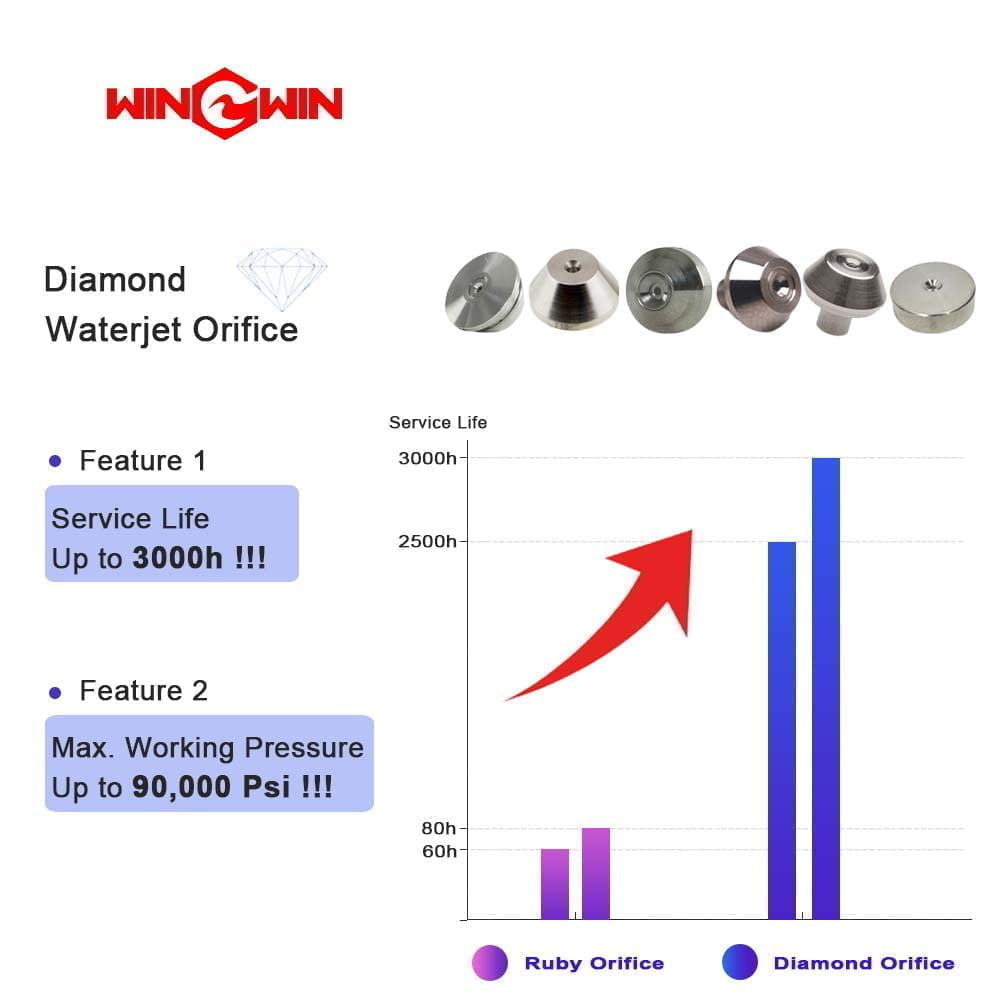

In the above two tables, you can see that when you want to buy water jet orifice, you need to consider the brand of the product. Different products of each brand have their corresponding unique numbers; and products of the same model have different Common materials of water jet orifice include ruby, sapphire and diamond. Common users use ruby and sapphire water jet orifice, and some users use diamond water jet orifice. The cost of diamond water jet orifice is relatively high, but The service life and the degree of wear to other related parts are better than the other two materials of water jet orifice. If you want to know the detailed product price of waterjet orifice, contact us to request a quote!

Waterjet Mixing Tube Standard Size: OD: 6.35mm,7.14mm, 9.45mm; ID: 0.76mm, 1.02mm; Length: 76.2mm, 101.6mm etc.

There are also many types of waterjet mixing tube products. You can see the ones in our pictures. There are three types from the appearance alone. One is only waterjet mixing tube, and the second is waterjet mixing tube with one The structure of the collet, there is another kind is that the waterjet mixing tube has a collet and a seal. The specific location of this depends on the brand and model, and the location will be different. You need to pay attention to this detail when purchasing. If you have doubts about this issue, you can consult us.

Usage of the Waterjet Mixing Tube:

In this picture you can see that the waterjet mixing tube is installed at the bottom of the waterjet cutting head, closest to the cutting material. The waterjet mixing tube is mainly used on the abrasive waterjet cutting machine. The function of waterjet mixing tube is to mix the pressurized ultra-high pressure water flow and abrasive garnet to form a high-speed flow of sand and water mixed stream, and to cut some relatively hard materials, such as stone, glass, metal etc. The size of the commonly used waterjet mixing tube is 7.14mm, and the inner diameter is 0.76mm or 1.02mm. Of course, there are some other sizes of sand tubes suitable for different brands of waterjet cutting machines. You can refer to the following table:

| 7.14×0.76(1.02)x76.2mm |

| 7.14×0.76(1.02)x101.6mm |

| 7.62×1.02×76.2mm |

| 6.35×0.76(1.02)x76.2mm |

| 8.0×1.02×101.6mm |

| 8.89×0.76×101.6mm |

| 9.45×1.02×76.2mm |

| 9.45×1.02×101.6mm |

| 9.52×1.02×76.2mm |

If you need a more detailed product catalog or price list of the waterjet mixing tube, please contact us!!!

Waterjet Orifice Waterjet Mixing Tube inspection & packing:

Our waterjet cutting parts have gone through strict inspection procedures and testing procedures before delivery. Only products that meet the standards can be ready to be sent to customers, so you can rest assured to try them on quality issues. And our product packaging is the best solution we found after research and several adjustments. We have sponges for collision-resistant and fragile products such as waterjet orifice and waterjet mixing tube, and then put them into hard plastic boxes, and then paste the corresponding product numbers and product details, such as the inner diameter of the product, The information about the diameter and length of the outer aperture will avoid customers from confusing the product and causing unnecessary trouble. Usually we have a large amount of these products in stock, because these two are the most common wearing parts in waterjet cutting machine, so the general customers will often replace them, usually we will suggest having a certain amount of stock for future use in A rainy day.

Waterjet Mixing Tube:

Our waterjet mixing tube is processed and produced with wear-resistant and good materials. After a large number of customers use, it has been proved that our product quality can win customers’ continuous return orders. You can actually see this waterjet mixing tube on the Internet. There are many products with different price points, and some even have several times the price difference. These actually depend on the size of the product, and another is the quality of the product.

Generally speaking, the price of common product sizes is relatively cheap, usually around US$30-50. If the waterjet mixing tube at this price is compared with the industry benchmark rotec, it is equivalent to rotec 200 or rotec300; There are also some good quality ones that may be around 80-150 US dollars. The quality of waterjet mixing tube products at this price is similar to that of rotec500 products. In short, the price and quality are directly proportional.

Compared with some uncommon product sizes, it will involve the problem of customized products. In this case, the price will usually be relatively expensive, usually about 20-30 dollars higher, and some are thicker size waterjet mixing tube, the prices of these products will be relatively high.

If you need waterjet mixing tube, you can contact us directly to get the specific product price.

Waterjet Orifice & Waterjet Mixing Tube feedback:

We have been operating waterjet cutting machine products for so many years and have won the trust and praise of many customers. We also sell waterjet nozzles on many B2C platforms, such as eBay, amazon, aliexpress, etc., and have also received unanimous praise from customers. If you have a purchase plan for these two accessories, you can contact us to get a quotation, or if you have questions about waterjet cutting machine, you can also contact us, we can provide free technical support.

Here are some common questions that people ask about waterjet orifice and waterjet mixing tube:

- What’s the different between the ruby orifice and the diamond orifice? – The price of Ruby orifice is relatively cheap, but the use time is much shorter than that of diamond orifice, which will increase the wear and tear of related parts; however, the price of diamond orifice is several times that of ruby orifice, and many customers may not be able to accept this price You need to decide according to your own budget and working conditions.

- What is the reason why the waterjet mixing tube is always blocked by abrasive? – This is the most frequently asked question about the waterjet mixing tube by customers. It may be that the inner diameter of the waterjet mixing tube is too small, or there is a problem with the adjustment of the sand supply, or it may be that the sand itself is damp or has a quality problem, etc. , there will be many influencing factors. For details, please refer to our other articles. If you still can’t solve it, you can directly contact us for technical guidance.

I am Linda from Win-Win Waterjet Co., Ltd. has been working at this company for almost six years. Served more than one hundred customers in glass cutting, metal cutting, stone cutting etc. Working in the waterjet industry for many years has also allowed me to accumulate a lot of waterjet related experience, including some common problems of products, the design of the cutting scheme, the operation of the machine, the maintenance of the machine and the replacement of parts, etc. These accumulated work experience It allows me to better serve my clientele. Of course, with the accumulation of time, I have also accumulated some loyal old customers who continue to repurchase related products of waterjet cutting from us. You can contact us for many questions about waterjet cutting machine or waterjet parts, including the specific parameters and models of orifices and mixing tubes, the installation and maintenance, and the service life of these waterjet parts etc. If you have any questions about waterjet cutting machine or looking for cutting solution, you can contact us, we can provide technical support for free.