Description

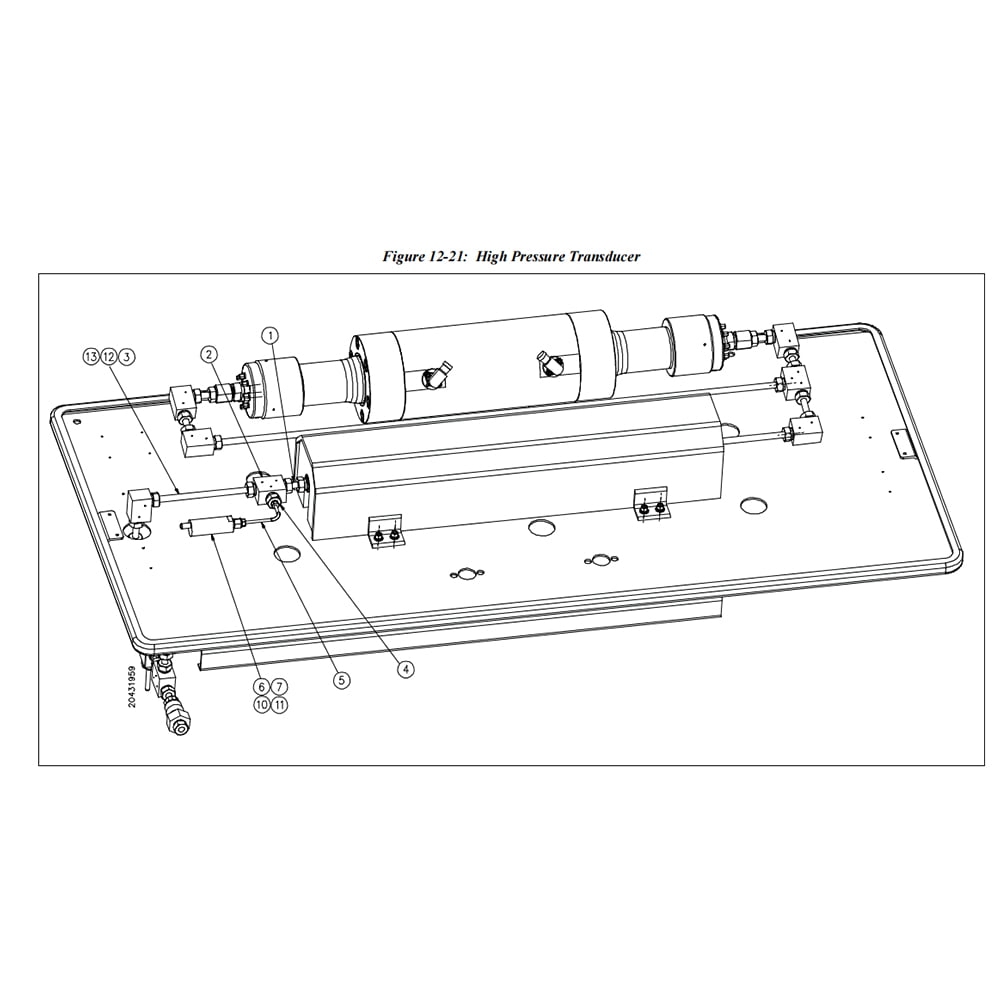

Item number : 20431959

Description: pièces jet d’eau high pressure transducer, used on the 100hp waterjet high pressure pump

Related product of waterjet pump:

| Numéro d’article | Description |

| 10069326 | HP Tube, .56 x 4.0 |

| 10079465 | Tee, HP, .56 |

| 20412627 | HP Tube, .56 x 11.50 1 |

| 10079580 | Bushing, HP, .56 x .25 1 |

| 05071782 | HP Tube, Bent, .25 1 |

| 49838478 | Pressure Transducer, 0-75,000 psi |

| 10067205 | Cable Connector, .50 1 |

| 10176410 | Wire, #16, Blue 100.0″ |

| 10185395 | Connector, Crimp Ferrule, #16 10 |

| 10078459 | HP Gland, .25 1 |

| 10078426 | HP Collar, .25 1 |

| 05086905 | Flexible Conduit, .63 12.0” |

| 05131347 | Ferrule, .50 |

FAQ of Waterjet Cutting Industry:

CNC Milling: CNC milling presents a versatile cutting solution employing rotating cutting tools to remove material from a workpiece. It suits a broad spectrum of materials, including metals, plastics, and wood. CNC milling is renowned for its capacity to deliver high precision and create intricate shapes and designs. It frequently finds application in prototyping, mold creation, and custom part production.

Laser Cutting: Laser cutting harnesses the power of a focused laser beam to cleanly cut through materials, proving especially effective with thin materials like sheet metal, acrylic, and wood. Laser cutting boasts exceptional precision, speed, and the ability to craft intricate designs. It is commonly employed in industries such as signage, electronics, and automotive manufacturing.

Waterjet Cutting: Waterjet cutting employs a high-pressure stream of water mixed with abrasive particles to effectively cut through a wide array of materials, including metals, stone, glass, and composites. Its reputation for versatility shines as it handles thicker materials while producing smooth edges without heat-affected zones. This method frequently finds favor in industries like aerospace, architecture, and fabrication.

In essence, CNC milling excels at precision cutting and intricate shapes, laser cutting is ideal for thinner materials and intricate designs, and waterjet cutting offers adaptability and the capability to cut diverse materials. The optimal choice hinges on your specific cutting project’s requirements, encompassing material type, thickness, design intricacy, and desired precision.