Description

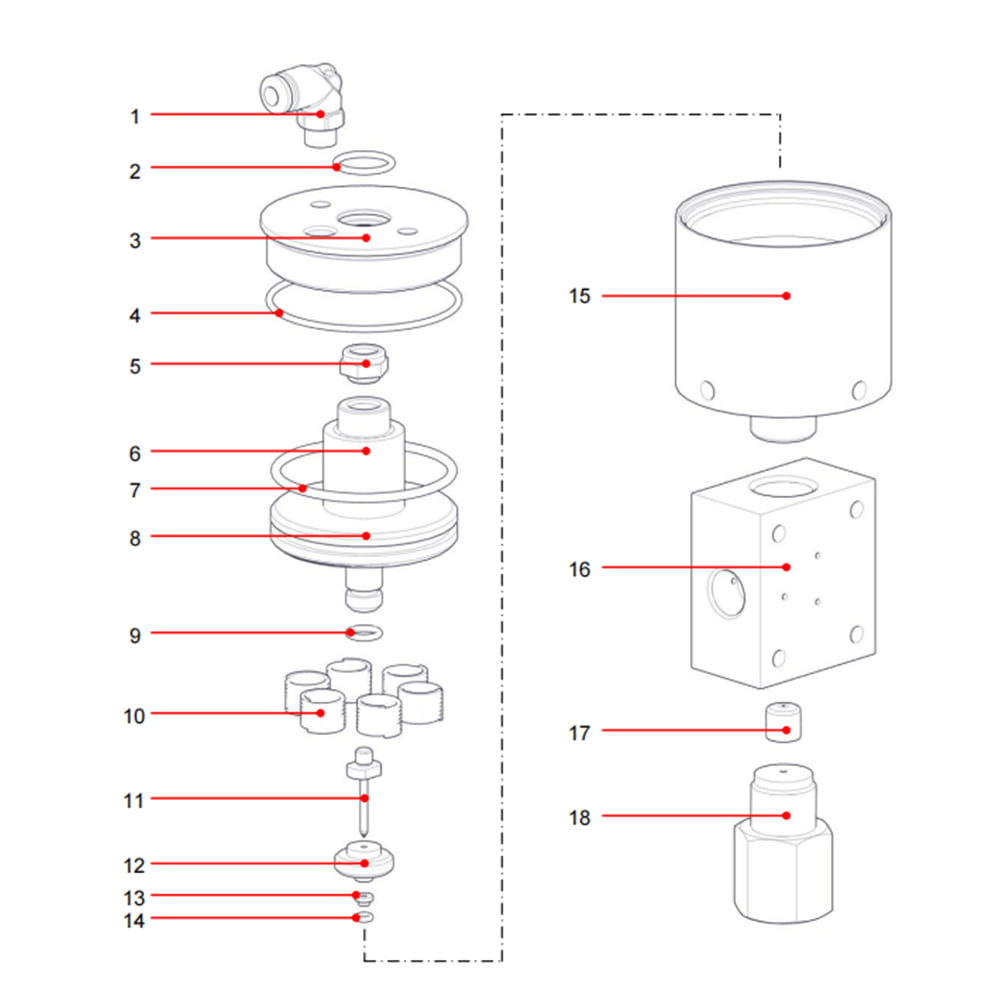

Pièces de découpe au jet d’eau Pièce de tête de coupe de soupape à pointeau à air comprimé

Numéro d’article : 1003725

Il existe quelques pièces de découpe au jet d’eau connexes pour l’ensemble de soupape :

| Numéro d’article | Description |

| 1002480 | Enfoncer le genou 6 x 1/8" |

| 1004403 | Joint torique |

| 1000801 | Couvrir |

| 1002838 | Joint torique |

| 1000767 | Écrou de grille |

| 1000804 | Bague |

| 1004402 | Joint torique |

| 1047774 | Piston NON |

| 1002836 | Joint torique |

| 1004206 | Source |

| 1000791 | Aiguille |

| 1002835 | Bague de butée d’étanchéité |

| 1002834 | Joint HP |

| 1001643 | Coupe |

| 1000805 | Corps de soupape |

| 1000796 | Siège |

| 1047750 | Adaptateur |

Autres pièces de découpe au jet d’eau connexes :

| 1027347 | Corps de soupape |

| 1004604 | Ensemble clapet anti-retour |

| 1003551 | Piston hydraulique |

| 1003544 | Vérin hydraulique |

| 1003644 | Boîtier du filtre |

| 1003433 | Adaptateur de clapet anti-retour |

| 1004146 | Vérin hydraulique |

| 1001653 | Bague d’étanchéité haute pression |

| 1009700 | Couplage |

| 1003302 | Filtre haute pression |

| 1004541 | Kit de réparation de clapet anti-retour |

| 1004386 | Bague de retenue du piston |

FAQ of waterjet cutting machine & waterjet accessories: How can I extend the life of my waterjet intensifier? Is there any good suggestion?

Afin de prolonger la durée de vie de l’intensificateur de jet d’eau, nous avons les suggestions suivantes à vous référer :

Toutes les conditions préalables : Il est important de suivre les procédures d’entretien appropriées et de respecter les paramètres de fonctionnement recommandés.

- Suivre les recommandations d’entretien du fabricant : procédures d’entretien spécifiques, inspection régulière des pièces découpées au jet d’eau, lubrification et remplacement des pièces usées ou endommagées, etc.

- Utilisez des accessoires de découpe à l’eau de bonne qualité : le meilleur choix est d’utiliser les accessoires d’origine de la même marque. Afin de réduire les coûts, vous pouvez également trouver des produits alternatifs, mais vous devez choisir un fournisseur de produits de découpe à l’eau de bonne réputation, et vous devez Paramètres spécifiques précis des accessoires de coupe à l’eau ; Les pièces telles que l’étanchéité sont très importantes, une fois que l’étanchéité n’est pas bonne, il est facile de causer le problème de la décharge de pression, entraînant une pression insuffisante, ce qui affectera l’effet de coupe et la vitesse.

- Surveillez strictement les paramètres de fonctionnement de la machine : Par exemple, la pression de nos pompes intensificatrices à jet d’eau courantes est généralement comprise entre 420 MPA. Si la pression de travail dépasse cette valeur maximale, cela peut endommager les pièces concernées ; Un autre est la pompe intensificatrice. La température de la machine de découpe doit également être prise en compte à tout moment. Si la température est trop élevée, la machine enverra une alarme pour arrêter le travail de coupe. Il est préférable d’utiliser toutes les données dans la plage de valeurs recommandée pour garantir l’état de fonctionnement à long terme de l’intensificateur.

- Formation du personnel d’exploitation : une formation correcte du personnel sur le fonctionnement, l’installation et la maintenance du personnel peuvent permettre au personnel d’effectuer un entretien correct lorsque la machine doit être entretenue, ce qui peut réduire le risque de défaillance et d’autres problèmes et augmenter la durée de vie.

Fondamentalement, en suivant ces conseils, vous pouvez prolonger la durée de vie de l’intensificateur de coupe à l’eau. Bien sûr, si vous rencontrez d’autres problèmes concernant la découpe à l’eau, vous pouvez également nous contacter. Nous avons du personnel d’entretien professionnel qui travaille dans l’industrie de la coupe de l’eau depuis plus de 20 ans. Les avis et suggestions de professionnels vous aideront à résoudre à temps les problèmes de coupe d’eau que vous rencontrez.