Description

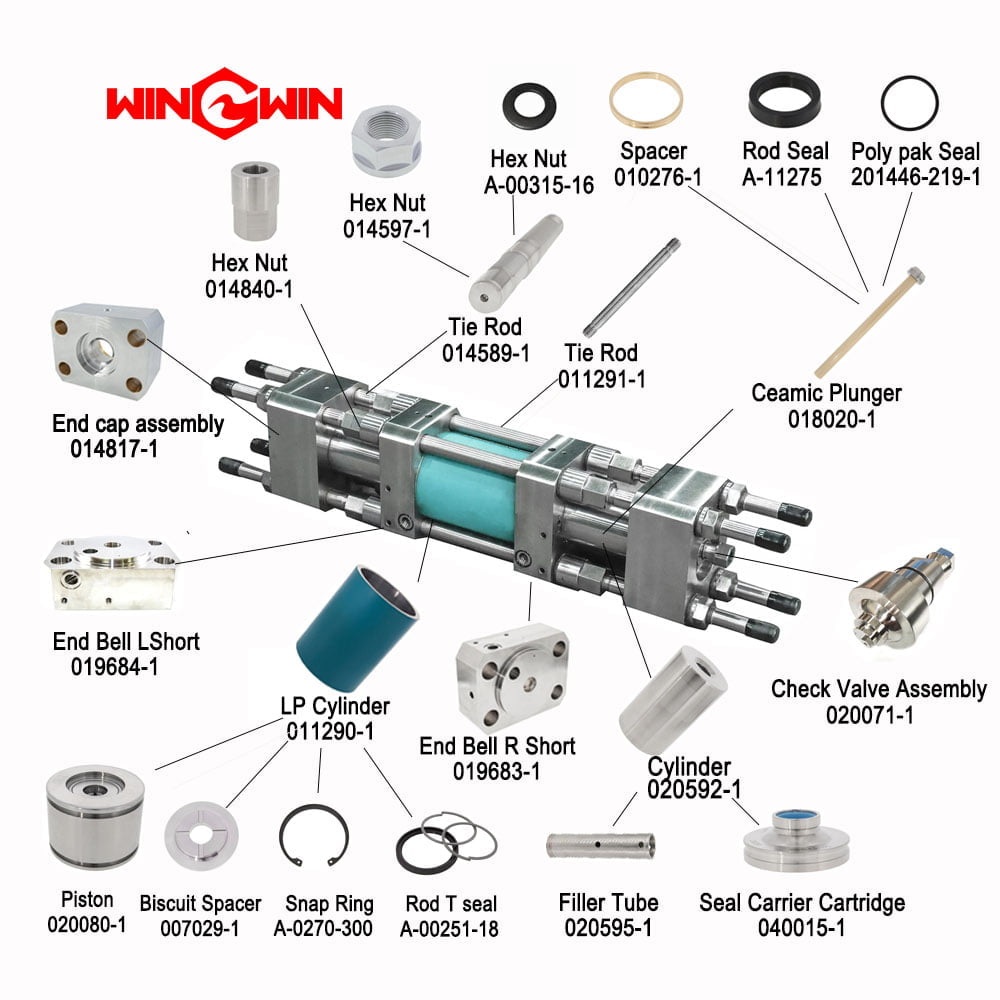

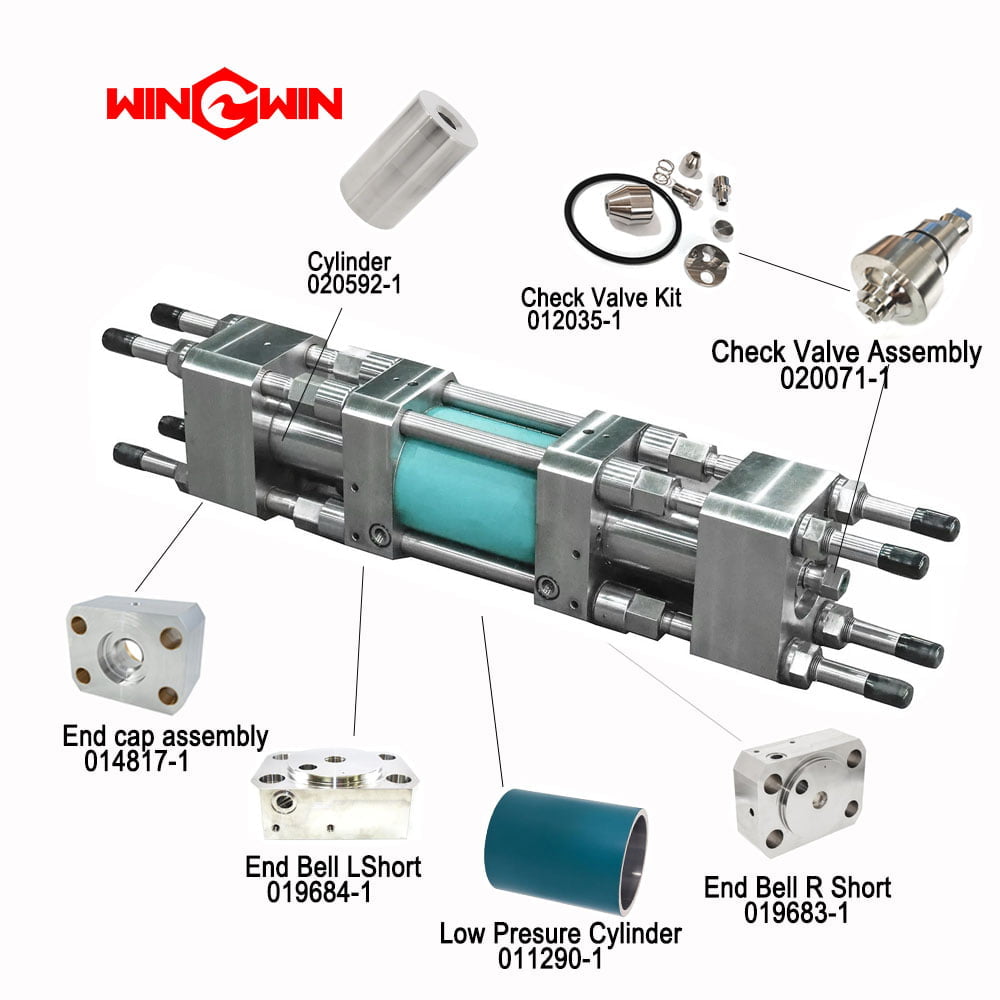

Water Jet Cutter Parts A-11275, the weight of this part is 0.2kg, in stock, the waterjet accessories can be shipped on the same day, and the fast logistics can arrive in about three days, the Waterjet parts A-11275 oil seal is suitable for 87k waterjet pump Above,

Oil Seal related parts: spacer 010276-1, 019683-1 end bell,

The oil seal of the 87k waterjet pump can be used normally for 6-8 months. The service life of the oil seal is related to the water quality and the smoothness of the surface of the ceramic rod. At the same time, the smoothness of the inner hole of the cylinder end cover is also related to wear. We recommend Customers use expensive oil seals because they are of good quality, which can reduce the failure rate and reduce the number of disassembly.

Water Jet Cutter Partsoften need to disassemble the supercharger to replace parts. In the end, the undamaged parts will cause damage. For example, the check valve and high-pressure cylinder are not damaged, but the high-pressure water seal or oil seal needs to be replaced, so the high-pressure cylinder and check valve need to be disassembled, which will cause damage to other water cutting accessories, and the metal seal between the high-pressure cylinder and check valve It belongs to the one-time compression structure. After the second local dismantling and re-installation, the airtightness of the first installation will not be achieved, so it will cause water leakage soon

Water Jet Cutter Parts A-11275 oil seal is installed in the hole in the middle of the cylinder end cover, with a retaining ring on it, and then positioned with a circlip. The middle of Water Jet Cutter Parts A-11275 oil seal is a ceramic rod. During the operation of the equipment, the plunger It will reciprocate, so during the operation of the machine, the inner wall of the oil seal will always be rubbed by the ceramic rod. If the water quality is not good and there are too many impurities in the water, the impurities in the water will adhere to the surface of the ceramic rod and will enter the ceramic rod and oil seal. Between the contact surfaces, the surface of the oil seal will soon be rough, which will seriously cause the surface of the ceramic rod to wear, which will cause pressure leakage, oil leakage or water leakage, resulting in machine failure.

Installing Water Jet Cutter PartsA-11275 oil seal requires professional water cutting tools. Using professional tools for installing Waterjet parts A-11275 oil seal will protect the oil seal. The installation can ensure concentricity and use for a longer time