Description

Pièces de cellule de jet d’eau de robot

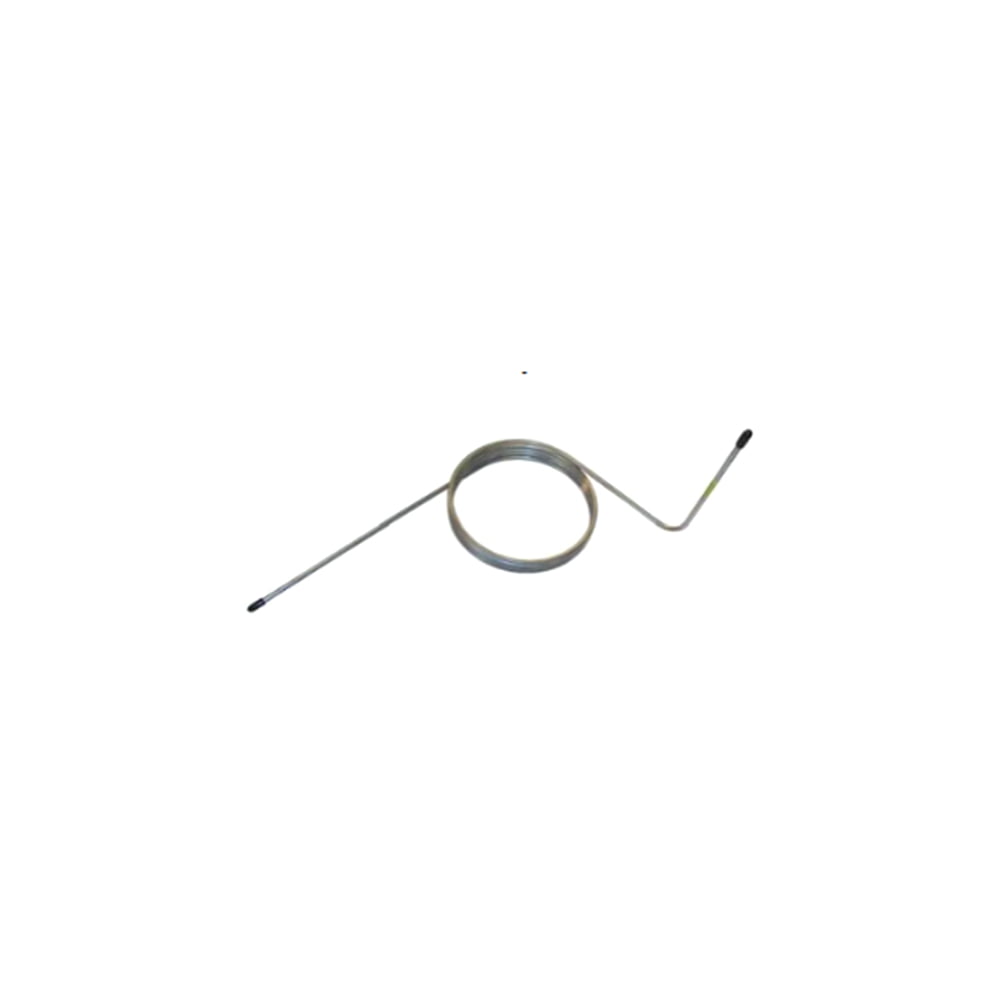

Item number: 304297 Spirale Achse 3/Coil Axis 3

Details: used on the ABB robot arms, robotic waterjet cutting workstation

Apparenté pièces de cellule de jet d’eau de robot:

Robotic waterjet cutting system: Yaskawa robotic waterjet workstation, Dual Fanuc robotic waterjet workstation, ABB robotic waterjet workstation

FAQ of platform waterjet machine & robot waterjet system & pièces de cellule de jet d’eau de robot:

Definition

Qu’est-ce que la découpe au jet d’eau ?

Waterjet cutting is a high-pressure stream of water for cutting technology or cleaning purposes, which is a machine that uses high-pressure water jet cutting. Under the control of the computer, the workpiece can be carved arbitrarily, and it is less affected by the texture of the material. Because of its low cost, easy operation, and high yield rate, waterjet cutting is gradually becoming the mainstream cutting method in industrial cutting technology. (Robot waterjet cell parts)

Classification

- According to the situation of adding abrasive: waterjet cutting is divided into two ways: pure waterjet and abrasive waterjet cutting.

- Divided by equipment: divided into large waterjet cutting machine, small waterjet cutting machine, three-dimensional waterjet cutting machine, dynamic waterjet cutting machine.

- Divided by pressure: divided into ultra-high pressure type, high-pressure type and low-pressure type, generally with 100MPa as the limit. Above 100MPa is high pressure type, below 100MPa is low pressure type. And above 200MPa is ultra-high pressure type.

- Divided by technical principles: divided into pre-mixed and post-mixed.

- Divided by safety cutting: divided into safety cutting and non-safety cutting, the difference is mainly in the water pressure, the low-pressure water cutting below 100MPa can be applied to special industries such as: hazardous chemical product, petroleum, coal mine, dangerous substance treatment, etc. (Robot waterjet cell parts)

Fonctionnalités

- CNC cutting a variety of complex patterns.

- It belongs to cold cutting and does not produce thermal deformation or thermal effect.

- Environmental protection, no pollution, no toxic gas and dust.

- It can process various high-hardness materials, such as: glass, ceramics, stainless steel, etc.. Or it can process relatively soft materials, such as: leather, rubber, paper diapers, etc..

- It is the only means to process some composite materials and fragile porcelain materials.

- After cutting, the incision is smooth, no slag, no secondary processing.

- Drilling, cutting and forming can be completed at one time.

- Low production cost.

- High degree of automation.

- It can work continuously for 24 hours.