Description

The O-Ring 05087713 is a type of sealing element of hydraulic piston assembly used in the 90,000 psi waterjet pump to prevent the leakage of fluids or gases.

This O-Ring has a specific size of 1.25 inches inner diameter, 1.50 inches outer diameter, and 0.13 inches thickness.

It is designed to fit into a specific groove or channel on a component to create a secure, tight seal that prevents fluid or gas from escaping.

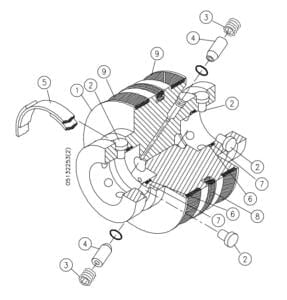

Article | Numéro de pièce | Description | Quantité |

1 | 72101205 | Piston Ram, 5.50 | 1 |

2 | 05074380 | Épingle Clevis | 12 |

3 | 05049887 | Vis de serrage | 2 |

4 | 10148757 | Ensemble clapet anti-retour | 2 |

5 | 05088364 | Bague | 2 |

6 | 05049994 | Anneau de sauvegarde, 1,50 x 1,75 | 2 |

7 | 05087713 | Joint torique, 1,25 x 1,50 x .13 | 2 |

8 | 05120118 | Assemblage de joints | 1 |

9 | 05120100 | Attitude | 2 |

| 72168337 | Kit de pièces de rechange | ||

| Comprend les articles 4, 5, 6, 7, 8 et 9 |

The O-Ring 05087713 is typically made of a rubber or elastomeric material that is selected based on the specific requirements of the application.

The material used in its construction can affect the O-Ring’s performance characteristics, including its ability to withstand high temperature, pressure, and chemical exposure.

O-Rings come in various sizes and shapes to fit different applications. The size of an O-Ring is typically measured by its inner diameter, outer diameter, and thickness.

Proper installation of an O-Ring is critical to ensuring reliable sealing and preventing equipment failure.

The O-Ring must be installed in a specific groove or channel on a component and must be compressed properly to create a secure, tight seal.

Q: How can I ensure that the O-Ring 05087713 is installed onto hydraulic piston assembly properly?

A: Proper installation of the 05087713 O-Ring is critical to ensuring reliable sealing and preventing equipment failure.

1. Clean the Components

Before installing the O-Ring, it is important to clean the components of hydraulic piston assembly that it will be sealing.

This can help to prevent contamination and ensure optimal performance.

2. Lubricate the O-Ring

Applying a small amount of lubrication to the O-Ring can help to ensure that it slides easily into the groove or channel on the component.

This can also help to prevent damage to the O-Ring during installation.

3. Position the O-Ring

Carefully position the O-Ring in the groove or channel on the component of hydraulic piston assembly.

Ensure that the O-Ring is properly seated and not twisted or deformed in any way.

4. Compress the O-Ring

Apply pressure to the component of hydraulic piston assembly to compress the O-Ring and create a tight seal.

Ensure that the O-Ring is compressed evenly and that it is not over-compressed, as this can cause damage to the O-Ring.

5. Inspect the O-Ring

After installation, inspect the O-Ring to ensure that it is properly seated and compressed. Look for signs of damage or deformation that could affect its performance.

By following these steps, you can ensure that the 05087713 O-Ring is installed properly and that it will provide reliable sealing in your application.

It is also important to consult the manufacturer’s guidelines for installation and maintenance of the O-Rings to ensure that you are following the recommended procedures.

Additionally, it is a good practice to inspect the O-Ring periodically after installation to ensure that it is still functioning properly and has not been damaged by the operating conditions or exposure to chemicals.

Regular inspection and maintenance can help to identify any issues with the O-Ring before they lead to equipment failure, allowing you to take proactive steps to ensure reliable sealing and prevent downtime.

Any other requirements for hydraulic piston assembly or 90,000 psi waterjet pump, please Contactez-nous.