Description

The Set Screw 05049887 is a component of the hydraulic piston assembly used in the 90,000 psi waterjet pump.

The set screw is a small, threaded screw that is used to secure other components of the hydraulic piston assembly in the pump.

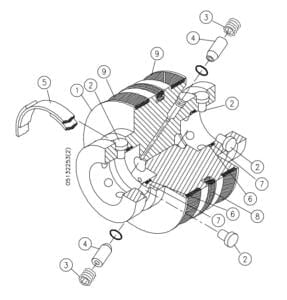

Article | Numéro de pièce | Description | Quantité |

1 | 72101205 | Piston Ram, 5.50 | 1 |

2 | 05074380 | Épingle Clevis | 12 |

3 | 05049887 | Vis de serrage | 2 |

4 | 10148757 | Ensemble clapet anti-retour | 2 |

5 | 05088364 | Bague | 2 |

6 | 05049994 | Anneau de sauvegarde, 1,50 x 1,75 | 2 |

7 | 05087713 | Joint torique, 1,25 x 1,50 x .13 | 2 |

8 | 05120118 | Assemblage de joints | 1 |

9 | 05120100 | Attitude | 2 |

| 72168337 | Kit de pièces de rechange | ||

| Comprend les articles 4, 5, 6, 7, 8 et 9 |

Specifically, the Set Screw 05049887 is used to secure the high-pressure seal retainer in the pump.

The high-pressure seal retainer is a component that helps to maintain the seal between the high-pressure water and the hydraulic oil in the pump.

The set screw helps to hold the retainer securely in place, preventing leaks and ensuring safe and effective operation of the pump.

The Set Screw 05049887 of hydraulic piston assembly is made of high-quality, durable materials to ensure reliable and long-lasting performance.

High-quality materials, such as steel or stainless steel, are typically used to make set screws for waterjet pumps.

It is designed to withstand the high pressures and stresses of the waterjet pump, and is manufactured to meet the required quality standards for safe and effective operation.

Q: How can I identify signs of wear or damage to the set screw of hydraulic piston assembly?

A:

1. Corrosion

Corrosion can occur on the surface of the set screw due to exposure to moisture or other environmental factors.

If you notice any signs of rust or discoloration on the surface of the set screw, it could be a sign of corrosion and potential wear or damage.

2. Stripped threads

Over time, the threads on the set screw can become stripped or worn, which can affect the ability of the screw to secure other components of hydraulic piston assembly.

If you notice that the set screw is difficult to tighten or loosen, or if you notice any signs of stripping or wear on the threads, it may be time to replace the screw.

3. Bending or warping

If the set screw has been subjected to excessive force or extreme temperatures, it may become bent or warped.

This can affect its ability to secure other components of hydraulic piston assembly and can cause issues such as leaks or reduced performance.

4. Missing or damaged head

If the head of the set screw is missing or damaged, it may be difficult or impossible to tighten or loosen the screw.

This can affect the ability of the screw to secure other components of hydraulic piston assembly and can cause issues such as leaks or reduced performance.

5. Excessive wear

Over time, the set screw may experience wear due to regular use or exposure to stress.

If you notice any signs of excessive wear, such as a flattened or worn surface, it may be time to replace the screw.

6. Looseness

If the set screw is not securely in place, it may become loose over time and may fail to hold other components of hydraulic piston assembly securely.

This can cause issues such as leaks or reduced performance.

7. Leaks

If you notice leaks around the area where the set screw is located, it could be a sign that the screw is not holding the component securely in place.

This may be due to wear or damage to the set screw or other components in the hydraulic system.

8. Difficulty adjusting or maintaining position

If you are having difficulty adjusting or maintaining the position of the component that the set screw is securing, it could be a sign that the screw is not holding the component securely in place.

This may be due to wear or damage to the set screw or other components in the hydraulic system.

9. Reduced performance

If the component being secured by the set screw is not performing as expected or is experiencing reduced efficiency or output, it could be a sign that there are issues with the set screw or other components in the hydraulic system that may be causing excessive stress or wear on the screw.

10. Unusual noises

If you hear unusual noises coming from the area where the set screw is located during operation, it could be a sign that there are issues with the set screw or other components in the hydraulic system that may be causing excessive stress or wear on the screw.

11. Reduced accuracy

If the component being secured by the set screw is not cutting or performing with the expected accuracy or precision, it could be a sign that there are issues with the set screw or other components in the hydraulic system that may be causing excessive stress or wear on the screw.

12. Excessive vibration

If the component being secured by the set screw is experiencing excessive vibration during operation, it could be a sign that there are issues with the set screw or other components in the hydraulic system that may be causing excessive stress or wear on the screw.

13. Debris or damage in the thread

If there is debris or damage in the thread of the set screw, it can prevent the screw from tightening properly or cause it to become stuck.

In this case, the screw may need to be removed and the threads cleaned or repaired.

Any other requirements for hydraulic piston assembly or 90,000 psi waterjet pump, please Contactez-nous.