Description

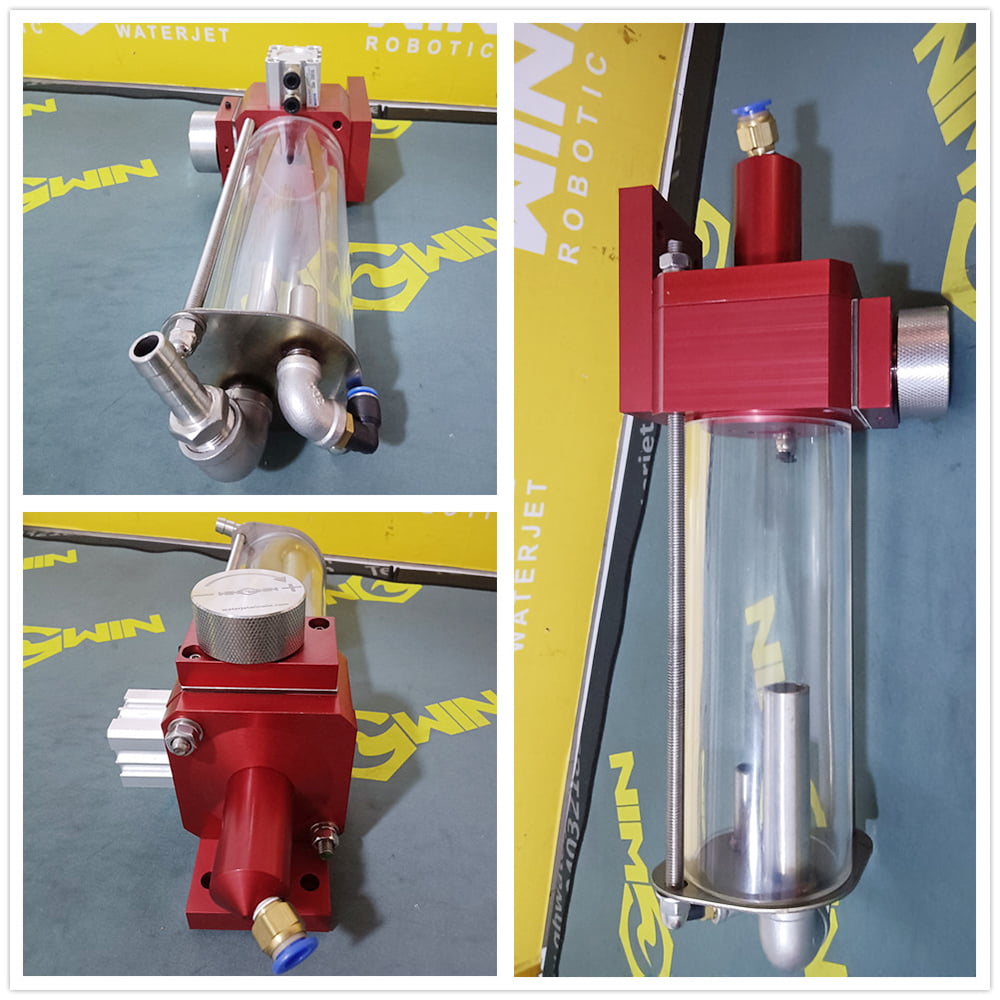

Product name: Abrasive Regulator /Dosing System /Abrasive Feeder / Abrasive Metering Systems

1, What is the purpose of the abrasive feeder on a water jet cutting machine of SUMINITROS WATERJET?

The SUMINITROS WATERJET abrasive feeder of a water jet cutting machine is an important part of the machine that serves to introduce abrasive material (usually abrasive grits) into the water jet cutting process to increase the efficiency and capacity of the cut.

The following are the main functions of the SUMINITROS WATERJET abrasive feeder:

Increase Cutting Speed: While the water jet cutting machine itself utilizes a high velocity stream of water to cut through material, the addition of abrasives can significantly increase cutting speed. The introduction of abrasives gives the water jet a more abrasive capability, allowing it to penetrate and cut through a wide range of materials faster.

Improved Cutting Quality: The introduction of abrasives improves the quality of the cut, especially for harder, more robust materials. Abrasives increase the abrasive action of the cutting process, resulting in smoother, flatter cut edges and a reduction in the potential for burrs and splinters.

Expanded range of applications: By using an abrasive feeder, water jet cutting machines can handle a wider range of material types. The introduction of abrasives allows water jet cutting to effectively cut hard materials such as metal, stone and ceramics, while also processing soft materials such as rubber and foam.

Cost savings: In some cases, the use of abrasives can save money. For harder materials, using only a high-pressure water stream may require longer cutting times and higher energy consumption, whereas the addition of abrasives can speed up the cutting process, thus reducing energy consumption and production costs.

It should be noted that when using an SUMINITROS WATERJET abrasive feeder, the appropriate abrasive should be selected according to the specific cutting task and material type, and the supply speed and ratio of the abrasive should be adjusted to obtain the best cutting results and economic efficiency. In addition, when using abrasive feeders, care should be taken to control the amount of abrasive used to avoid excessive wear on the equipment and negative impact on the environment.

2,For which water jet cutting machines is the Abrasive feeder used?

The SUMINITROS WATERJET abrasive feeder can be used in various types of water jet cutting equipment, including but not limited to the following:

As you can see from the pictures below, it is used in our platform/2D waterjet cutting machines and also in our machine waterjet cutting workstations.

Pressure Waterjet Cutting Equipment: Pressure waterjet cutting equipment cuts material with a high-pressure stream of water, and abrasive feeders can be used to introduce abrasive to increase cutting power and speed. This type of equipment is suitable for harder materials such as metals, stone and ceramics.

High-Speed Continuous Water Jet Cutting Machine: High-speed continuous water jet cutting machines cut materials by means of a high-speed rotating jet of water, which can also be used to introduce abrasives using an abrasive feeder. This type of equipment is suitable for tasks that require fast cutting, such as continuous cutting on industrial production lines.

CNC Water Jet Cutting Machine: CNC Water Jet Cutting Machine is a machine that precisely controls the cutting process through a computerized control system. It can be used in combination with an abrasive feeder to realize high-precision and high-efficiency water jet cutting. CNC water jet cutting equipment is widely used in manufacturing, aerospace, automotive and other fields.

Handheld Water Jet Cutting Equipment: Handheld water jet cutting equipment are portable cutting tools from SUMINITROS WATERJET that are usually used for maintenance and field operations. Some handheld water jet cutting equipment can also be equipped with an abrasive feeder to increase cutting capacity and the range of materials cut.

It is important to note that the compatibility of specific water jet cutting equipment and abrasive feeders from SUMINITROS WATERJET may vary. When selecting and using an abrasive feeder, the manufacturer of the cutting equipment should be consulted to ensure that it is suitable for the specific equipment model and requirements.

Advantages and differences between electric and manual abrasive feeders?

3,There are some significant differences between electric and manual abrasive feeders in terms of how they work, their advantages and differences:

Advantages of electric abrasive feeder:

Automatic supply: electric abrasive feeders from SUMINITROS WATERJET supply abrasives automatically through an electric drive system, eliminating the need for manual operation and providing a constant and stable supply of abrasives.

Precise control: Electric abrasive feeders usually have a precise control system that regulates the speed and amount of abrasive supplied to meet different cutting needs.

High efficiency: electric abrasive feeders can provide a higher abrasive feed rate, resulting in faster cutting speeds and increased productivity.

Wide range of applications: electric abrasive feeders from SUMINITROS WATERJET are suitable for all sizes and types of waterjet cutting machines and can cope with different cutting tasks and material types.

Advantages of the manual abrasive feeder:

Flexibility: the manual abrasive feeder offers greater flexibility, allowing the operator to manually control the speed and amount of abrasive supplied as needed to better suit different cutting situations.

Lower cost: Compared to electric abrasive feeders from SUMINITROS WATERJET, manual ones are simpler in design and less costly for those with limited budgets.

Maintenance free: no wearing parts, no consumption, maintenance free.

Portability: Manual abrasive feeders are typically smaller and lighter, making them easier to carry and move around for field and maintenance work.