Description

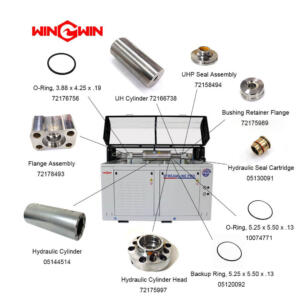

UH Cylinder 72166738 applied to the 90000 psi waterjet intensifier pump.

The main components of a 90000 psi waterjet intensifier pump are:

1. Hydraulic system: Provides the driving force to intensify the water pressure.

2. Intensifier assembly: Converts the low-pressure water into high-pressure water using a reciprocating mechanism.

3. UH cylinder: Holds and seals the high-pressure water produced by the intensifier assembly.

4. UH pressure connections: Connect the high-pressure water output of the UH cylinder to the cutting head.

Article | Numéro de pièce | Description | Quantité | Article | Numéro de pièce | Description | Quantité |

1 | 05146592 | Joint d’étanchéité, Topworks Support | 2 | 14 | 72162253 | Ventouse | 2 |

2 | 20476377 | Soutien, Topworks | 2 | 15 | 05130091 | Cartouche de joint hydraulique | 2 |

3 | 10118206 | Joint torique, 1.31×1.56× .13 | 2 | 16 | 72175989 | Bride de retenue de bague | 2 |

4 | 05144514 | Vérin hydraulique | 1 | 17 | 72158494 | Assemblage de joints UHP | 2 |

5 | 05098991 | Vis à tête creuse, 3/8-16×3-3/4 | 8 | 18 | 72166738 | Cylindre UHP | 2 |

6 | 95688743 | Rondelle de blocage, .38 | 8 | 19 | 72163802 | Paquebot | 2 |

7 | 72101190 | Assemblage du piston | 1 | 20 | 20474325 | Goujon, 1-1/8-12×18.31 | 8 |

8 | 10074771 | Joint torique, 5.25×5.50× .13 | 2 | 21 | 72170157 | Assemblage de la tête de scellage | 2 |

9 | 05120092 | Anneau de secours, 5.25×5.50× .13 | 2 | 22 | 72178493 | Assemblage de brides | 2 |

10 | 72175997 | Culasse hydraulique | 2 | 23 | 20464590 | Rondelle plate, 1.13 | 8 |

11 | 05097886 | Vis à tête creuse, 3/4-16×2-1/4 | 12 | 24 | 20461761 | Écrou hexagonal, 1-1/8-12 | 8 |

12 | 05144183 | Ensemble d’entretoise, interrupteur de proximité | 2 | 25 | 20489339 | Adaptateur, JIC/Tuyau, 50× .38 | 1 |

05144191 | Joint torique, .69× .88× .09 | 26 | 72176756 | Joint torique, 3,88×4,25× .19 | 6 | ||

13 | 72141569 | Kit, Détecteur de proximité | 2 | ||||

| 72134224 | Commutateur de proximité | ||||||

95119012 | Vis à tête creuse, 1/4-20×1 |

The UH (Ultra High-pressure) cylinder is a crucial component of a 90000 psi waterjet intensifier pump.

And it is a part of the high-pressure side of the 90000 psi waterjet pump.

The UH cylinder specifically serves the following purposes:

– Containment:

The UH cylinder is designed to house and contain the high-pressure water produced by the intensifier assembly.

It is made of high-strength materials, such as stainless steel or other corrosion-resistant alloys, to withstand the extreme pressures involved in the process.

– Sealing:

The UH cylinder is equipped with multiple seals, such as dynamic and static seals, to prevent the high-pressure water from leaking out.

These seals are typically made of wear-resistant materials, like polyurethane or PTFE (Teflon), to ensure a long service life.

– Guidance:

The UH cylinder works in conjunction with other components of the 90000 psi waterjet intensifier pump to create the high-pressure waterjet.

It also provides guidance for the movement of the high-pressure plunger.

Water is first drawn into the low-pressure side of the pump and then pressurized by a reciprocating piston or plunger.

This plunger moves back and forth within the UH cylinder, driven by the hydraulic system, to generate high-pressure water.

The pressurized water is then sent through a check valve and into the UH cylinder, which further increases the pressure of the water to the desired level.

These parts create a closed circuit within the cylinder.

As the pressurized water flows through the cylinder, the seals and check valves work together to increase the pressure to the desired level.

What are some common issues that can arise with the UH cylinder in 90000 psi waterjet pump?

Here are a few of the most common ones:

1. Leakage

One of the most common issues with the UH cylinder is leakage. This can occur due to wear and tear on the seals or other components within the cylinder.

If not addressed promptly, leakage can lead to a loss of pressure and reduced performance of the 90000 psi waterjet.

2. Blockages

Another issue that can occur with the UH cylinder is blockages. This can happen if debris or other foreign objects get into the cylinder and obstruct the flow of water.

Blockages can cause the waterjet to become less effective or even stop working altogether.

3. Misalignment

The UH cylinder must be properly aligned with other components of the 90000 psi waterjet intensifier pump in order to function correctly.

If there is misalignment, it can cause excessive wear and tear on the cylinder and other components, leading to poor performance or even damage to the pump.

4. Corrosion

The high-pressure water flowing through the UH cylinder can cause corrosion over time. If left unchecked, corrosion can weaken the cylinder and lead to failure.

5. Fatigue

The UH cylinder is subjected to high cyclic loading during operation, which can lead to fatigue failure over time.

This can be addressed through proper design and material selection, as well as regular inspection and maintenance.

6. Overheating

If you notice that the 90000 psi waterjet pump is overheating or producing excessive heat, it could be a sign of an issue with the UH cylinder.

Overheating can be caused by a variety of issues, including blockages, misalignment, or other problems that are preventing the cylinder from functioning properly.

7. Unusual smells

If you notice any unusual smells coming from the 90000 psi waterjet pump, it could be a sign of a problem with the UH cylinder.

This could be caused by overheating or other issues that are affecting the operation of the cylinder.

8. Reduced lifespan

If the UH cylinder is not maintained properly, it can lead to a reduced lifespan of the 90000 psi waterjet pump.

This can result in increased downtime, repair costs, and other issues that can impact your operations.

9. Inconsistent performance

If the 90000 psi waterjet pump is not providing consistent performance, it could be a sign of an issue with the UH cylinder.

This could be due to blockages, leaks, or other issues that are affecting the pressure and flow of the waterjet.

10. Visual inspection

Regular visual inspection of the UH cylinder can help to identify any signs of wear and tear, corrosion, or other issues that may require maintenance or replacement.

This can include cracks, dents, or other damage to the cylinder.

To ensure the efficient operation of a 90000 psi waterjet intensifier pump, it is important to perform regular maintenance on its components, including the UH cylinder.

This may involve inspecting and replacing seals, checking for corrosion or damage, and ensuring proper lubrication of moving parts.

By keeping the UH cylinder in optimal condition, you can help extend the life of your waterjet cutting system and maintain its cutting performance.

Any other requirements, please Contactez-nous.