Description

The 90000 psi pump parts Packing Seal 05027255 is a high-pressure seal used in waterjet pumps.

It is designed to provide a tight seal between the plunger and the high-pressure cylinder, preventing leakage of the high-pressure water used in waterjet cutting applications.

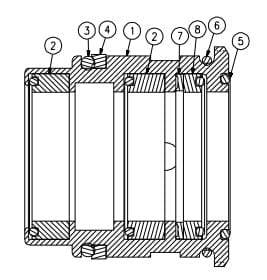

Article | Numéro de pièce | Description | Quantité |

1 | 05130109 | Seal Bushing | 1 |

2 | 05015060 | Packing Ring | 2 |

3 | 10193522 | O-Ring, 1.19 x 1.38 x .09 | 1 |

4 | 05050760 | Backup Ring | 1 |

5 | 05129481 | O-Ring, 1.0 x 1.13 x .06 | 1 |

6 | 05013024 | O-Ring, 1.25 x 1.38 x .06 | 1 |

7 | 05129515 | Backup Ring | 1 |

8 | 05027255 | Packing Seal | 1 |

| 80084759 | Rebuild Kit | ||

| Includes Items 2-8 |

The Packing Seal is typically made from a high-strength, wear-resistant material such as polyurethane or PTFE (polytetrafluoroethylene).

It is positioned between the plunger and the high-pressure cylinder, and is held in place by a packing retainer.

Over time, the Packing Seal can become worn or damaged due to exposure to high pressure and abrasive materials.

Signs of wear or damage to the Packing Seal may include excessive leakage, reduced pressure, or visible damage to the seal itself.

To replace the Packing Seal 05027255, you will need to remove the existing seal and packing retainer from the waterjet pump and install the new seal in its place.

Overall, the 90000 psi pump parts Packing Seal 05027255 plays a critical role in the efficient operation of waterjet pumps.

Regular maintenance and replacement of the Packing Seal, along with other critical components, can help to prevent downtime and costly repairs.

It can also help to ensure that the pump operates reliably and efficiently, with minimal risk of leaks or other problems.

Proper installation of the Packing Seal is critical to ensuring the efficient operation of your high-pressure waterjet pump.

Using the correct tools and techniques during installation can help to prevent damage to the Packing Seal and other 90000 psi pump parts.

Ensure that the seal is properly positioned and provides a tight seal between the plunger and the high-pressure cylinder.

Here are the correct tools and techniques for installing the Packing Seal:

1. Use a Packing Installation Tool

A Packing Installation Tool is a special tool designed to make it easier to install the Packing Seal.

This tool helps to position the Packing Seal correctly and helps to prevent damage to the seal during installation.

The tool is typically made from a non-marring material such as plastic or rubber and is designed to fit the shape and size of the Packing Seal.

2. Use a Packing Retainer Tool

A Packing Retainer Tool is used to install the packing retainer that holds the Packing Seal in place.

The tool is designed to fit the shape and size of the packing retainer and helps to ensure that the retainer is properly positioned and tightened to the correct specifications.

3. Use a Torque Wrench

A torque wrench is used to tighten the packing retainer to the correct specifications.

This helps to ensure that the retainer is properly tightened without over-tightening, which can cause damage to the Packing Seal or other components.

4. Use the Correct Lubricant

Using the correct lubricant during installation helps to reduce friction and prevent damage to the Packing Sealand other 90000 psi pump parts.

Be sure to use a lubricant that is compatible with the materials used in your waterjet pump.

Apply a thin layer of lubricant to the Packing Seal before installation to help it slide into place easier.

5. Follow Manufacturer Guidelines

Follow our guidelines for installation, including torque specifications, installation order, and any other instructions specific to your waterjet pump model.

6. Inspect for Damage

Before installing the Packing Seal, inspect it for any damage or defects.

If you notice any damage or defects, replace the Packing Seal before installation.

7. Clean the High-Pressure Cylinder

Before installing the Packing Seal, clean the high-pressure cylinder to remove any debris or dirt that could cause damage to the seal.

Use a clean cloth or other approved cleaning material to wipe down the cylinder.

Any other requirements for 90000 psi pump parts, please Contactez-nous.