Description

90000 PSI Pump Spare Parts: O-Ring, 5.25 X 5.50 X .13 10074771

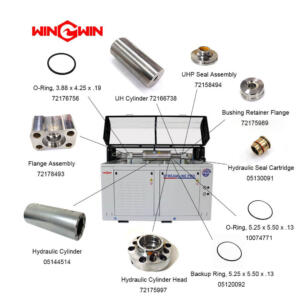

Article | Numéro de pièce | Description | Quantité | Article | Numéro de pièce | Description | Quantité |

1 | 05146592 | Joint d’étanchéité, Topworks Support | 2 | 14 | 72162253 | Ventouse | 2 |

2 | 20476377 | Soutien, Topworks | 2 | 15 | 05130091 | Cartouche de joint hydraulique | 2 |

3 | 10118206 | Joint torique, 1.31×1.56× .13 | 2 | 16 | 72175989 | Bride de retenue de bague | 2 |

4 | 05144514 | Vérin hydraulique | 1 | 17 | 72158494 | Assemblage de joints UHP | 2 |

5 | 05098991 | Vis à tête creuse, 3/8-16×3-3/4 | 8 | 18 | 72166738 | Cylindre UHP | 2 |

6 | 95688743 | Rondelle de blocage, .38 | 8 | 19 | 72163802 | Paquebot | 2 |

7 | 72101190 | Assemblage du piston | 1 | 20 | 20474325 | Goujon, 1-1/8-12×18.31 | 8 |

8 | 10074771 | Joint torique, 5.25×5.50× .13 | 2 | 21 | 72170157 | Assemblage de la tête de scellage | 2 |

9 | 05120092 | Anneau de secours, 5.25×5.50× .13 | 2 | 22 | 72178493 | Assemblage de brides | 2 |

10 | 72175997 | Culasse hydraulique | 2 | 23 | 20464590 | Rondelle plate, 1.13 | 8 |

11 | 05097886 | Vis à tête creuse, 3/4-16×2-1/4 | 12 | 24 | 20461761 | Écrou hexagonal, 1-1/8-12 | 8 |

12 | 05144183 | Ensemble d’entretoise, interrupteur de proximité | 2 | 25 | 20489339 | Adaptateur, JIC/Tuyau, 50× .38 | 1 |

05144191 | Joint torique, .69× .88× .09 | 26 | 72176756 | Joint torique, 3,88×4,25× .19 | 6 | ||

13 | 72141569 | Kit, Détecteur de proximité | 2 | ||||

| 72134224 | Commutateur de proximité | ||||||

95119012 | Vis à tête creuse, 1/4-20×1 |

What are some common signs of wear or damage to look for in O-rings applied to 90000 PSI pump?

1. Cracks or splits

O-rings may develop small cracks or splits over time, particularly if they are exposed to high temperatures or abrasive fluids.

These cracks or splits can cause leaks in the hydraulic system, which can reduce the efficiency of the 90000 PSI pump and potentially damage other components.

2. Swelling

O-rings may swell or expand if they come into contact with certain chemicals or fluids that are not compatible with their material composition.

This can cause the O-ring to lose its shape or become dislodged from its intended position, which can lead to leaks or other issues.

3. Hardening or stiffening

O-rings may become hardened or stiff over time, particularly if they are exposed to high temperatures or pressure.

This can cause the O-ring to lose its flexibility and ability to form a tight seal, which can lead to leaks or other issues.

4. Flattening or distortion

O-rings may become flattened or distorted if they are subjected to uneven pressure or are not properly installed.

This can cause the O-ring to lose its ability to form a tight seal, which can lead to leaks or other issues.

5. Wear or fraying

O-rings may wear or fray over time due to repeated cycles of compression and expansion.

This can cause the O-ring to lose its shape or become dislodged from its intended position, which can lead to leaks or other issues.

6. Chemical damage

O-rings may be damaged by exposure to certain chemicals or fluids, which can cause them to become brittle, swell, or lose their shape.

It’s important to choose O-rings that are compatible with the specific chemicals or fluids used in your 90000 PSI pump.

And you should also regularly inspect them for signs of chemical damage.

7. Âge

O-rings may degrade over time due to exposure to heat, pressure, and other factors.

Even if an O-ring appears to be intact, it may no longer be able to form a tight seal due to age-related degradation.

It’s important to regularly inspect O-rings for signs of age-related wear or damage, and to replace them as needed.

Any other questions, please Contactez-nous.