ABB Robotic Waterjet Cutting Workstation for Car Carpet Cutting

We know that robots have a wide range of uses. In addition to handling, they are also widely used in cutting, such as matching laser cutting, flame cutting, and of course water jet cutting.

And what is the use of robotic water cutting?

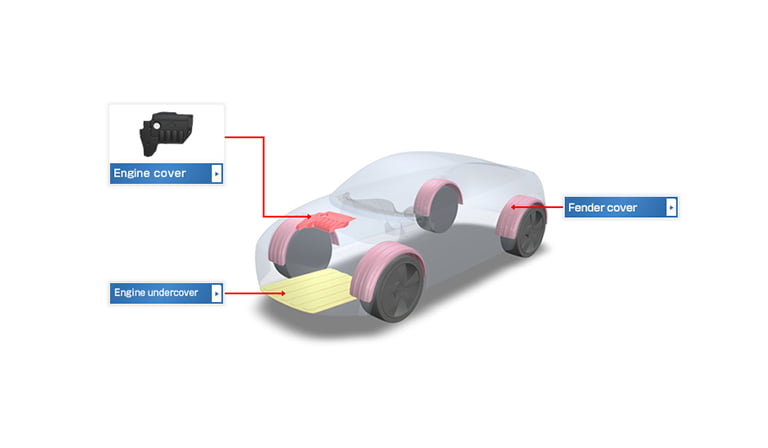

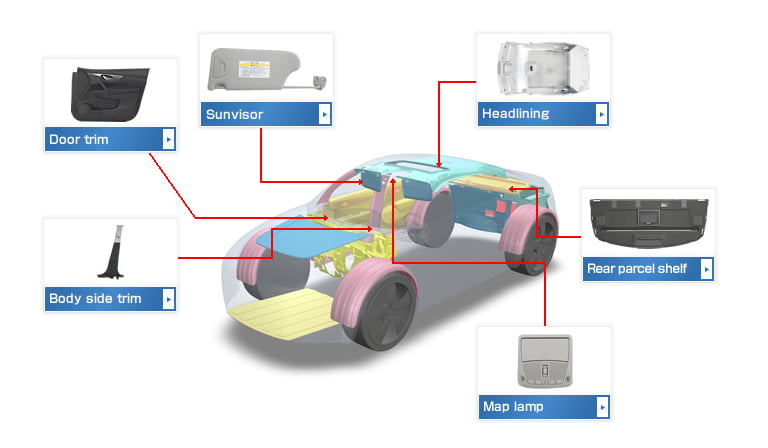

The first is the use of the interior and exterior of the car. We will update videos on YouTube (en inglés). You can see which parts we can cut through the following pictures.

For example: cutting automotive carpet door trim headlining car Engine cover Engine undercover Fender cover Rear parcel shelf cut, etc.

The water jet cutting robot is very flexible and runs very fast. Its cutting head can rotate 360 degrees, so it can realize cutting at various angles. It can not only cut horizontally, vertically, cut edges or middle, or gaps no problem. In addition to cutting, you can also punch holes, all kinds of small, large, round, square, triangular, and rectangular are no problem.

So what should you pay attention to when choosing a water jet robot manufacturer and machine configuration?

First of all, it is necessary to verify the strength of the supplier, such as product quality, technical experience, service, etc., which are very critical.

First of all, we know that the quality directly determines the use experience and work efficiency of the machine.

Technical experience is as important as quality. If the quality is good, but there is no good technical team, then they may not be able to achieve the optimization of Robotic Waterjet Cutting, whether it is from design, assembly, etc., they will not be able to achieve the desired work effect and efficiency.

And service is also a very direct aspect to show the strength of a supplier. Good service can make users feel at ease, can think of what users think, and respond to users’ questions and requests for help in a timely manner.

Regarding the technical experience of the Robotic Waterjet Cutting supplier, let me cite a case, we can see how important technical experience is to users. It can really reduce troubles for users and save labor and labor for users for Robotic Waterjet Cutting. Expense costs, that is, directly improve production efficiency.

There is a user of Yaskawa’s ceiling type dual robot arm of Robotic Waterjet Cutting workstation. He bought this robotic waterjet cutting workstation from another supplier. The supplier also installed it for them and put it into use. However, during the use process of Robotic Waterjet Cutting, he found that The 4-axis coil of the robotic arm of Robotic Waterjet Cutting workstation is very vulnerable to damage and leaks. They don’t know the reason, and they usually need to be replaced once a month, and each replacement operation is difficult, it takes a lot of energy and time, and it also causes a waste of cost and efficiency, which makes users very distressed.

Later, he came to us to maintain and maintain the robot for him. We found that the coil of the robot was flawed in design. The 4-axis and 5-6-axis coils of the original robot were separated, and the 4-axis was on the top of the 5-6-axis arm. , and then pass through the middle of the mechanical arm. This design makes the coil very easy to wear and difficult to replace.

Usually our design is that the 4-axis, 5-axis and 6-axis are integrated, and they are installed at the front of the robot arm. This design not only has a longer service life of the parts, usually more than three months, and many can even reach 6 months. . Moreover, the replacement is easier, which can save the user cost and labor costs, and can also improve production efficiency of Robotic Waterjet Cutting.

Later, we upgraded the coil design and installation method for the users. After using it, the users were very satisfied. We solved their problems and made the use of the robotic waterjet cutting machine smoother.

So we can see from the above cases how important it is for Robotic Waterjet Cutting users to have a professional and experienced supplier.

And good service is also one of the keys to choosing a supplier. The supplier provides you with comprehensive, meticulous, active, and fast services, which will really make users feel warm and caring, instead of just dealing with problems, or It is very uncomfortable and angry that the person in charge cannot be found at all.

This diagram shows the whole process from construction to testing, completion, packaging, shipping, Win-Win is professional for Robotic Waterjet Cutting.

The choice of high-pressure pump for Robotic Waterjet Cutting workstation is very critical.

If you want to use 1-4 Robotic Waterjet Cutting arms to work at the same time, or you want to improve the cutting efficiency of your Robotic Waterjet Cutting workstation, or you want to choose a high-pressure pump with longer service life and lower failure rate for Robotic Waterjet Cutting?

Then you can consider to choose Win-Win’s SCREMLINE SL-VI (100HP) pump for your Robotic Waterjet Cutting, which is unique among Chinese water jet suppliers, and it is compared to the pump with the same configuration of the well-known American brand.

Due to the optimization of its structure and design, its flow rate is very large, so it can drive multiple cutting heads to work at the same time for Robotic Waterjet Cutting, and it adopts hard seal, which has a long service life. Generally speaking, it only needs to replace a set of high-pressure sealing components in half a year, and the failure rate is extremely Low, it can definitely meet your high standards and strict requirements for the Robotic Waterjet Cutting machine.

We know that carbon fiber, which is very popular in the international market now, is a high-strength and modulus high-temperature-resistant fiber. It is a high-end variety of chemical fiber. The characteristics of carbon fiber, such as high hardness, high strength, light weight, high chemical resistance, and High temperature and low thermal expansion make it very popular in aerospace engineering, civil engineering, military, racing and other competitive sports products. However, carbon fiber is quite expensive relative to similar fibers, such as glass fibers or plastic fibers.

Carbon fibers are often combined with other materials to form composites. A carbon fiber reinforced polymer (also commonly referred to as carbon fiber) that has a very high strength-to-weight ratio when mixed with a plastic resin and wound or molded.

So do you know what machines can be used to cut carbon fiber?

Generally speaking, carbon fiber raw materials can be cut with engraving machines, milling cutters, saws, etc. without being combined with other materials to form composite materials, but after forming composite materials, they can be cut with water jets.

So what kind of machine can be used to cut thinner materials such as blister materials and ABS? Often engraving machines, water jet cutters, etc. are also options.

There are also glass fiber materials, such as quartz fiber, which are afraid of water, so they cannot be cut with a water jet cutting machine, but if other materials are added and processed to become composite materials, then water cutting can be used.

But as to which machine to choose for cutting, it depends on the cutting requirements and cutting effect, and compares the cutting characteristics of different machines. Of course, budget is also one of the factors that need to be considered.

So what kind of machine can be used to cut composite materials?

There are many types of composite materials with the same, they have different characteristics and cutting difficulty. Generally speaking, the cutting of composite materials requires the use of specialized cutting equipment to avoid damage to the material and also to ensure the precision and efficiency of cutting.

The following are a few commonly used composite material cutting equipment:

CNC Cutting Machines: CNC Cutting Machines are capable of precisely controlling the movement path of the cutter and can be used to cut composite materials of various shapes and sizes. These machines typically use either a high-speed rotating tool or a laser beam for cutting.

Water Jet Cutting Machines: Water jet cutting machines use high pressure water either with abrasives or with abrasives to cut materials of all hardnesses including metal, stone and composites.

Laser Cutting Machines: Laser cutting machines can efficiently cut a variety of composite materials, especially those with high fiber content. Laser cutting machines use a high-energy laser beam for cutting, allowing for high precision and speed.

Wire cutters: Wire cutters use a high-speed rotating wire cutter to cut, and can be used to cut a variety of shapes of composite materials. These machines are typically used to cut thicker composites.

If you encounter any cutting problems in any production, you can find Win-Win, we will provide you with technical consultation, reference and suggestions, and choose the appropriate cutting method for you. We are responsible for users and professional Please rest assured that we will not blindly recommend water jet cutting, but will consider it from the user’s point of view and choose the most suitable instead of the most expensive cutting method.

If you need to know more knowledge of waterjet cutting and robotic waterjet cutting, please contact us.