Solución de corte por chorro de agua YASKAWA Robot

| 1 | Marca del robot: | YASKAWA |

| 2 | Quanlity del robot: | soltero |

| 3 | Tipo de robot: | Pedastal |

| 4 | Número de producto del robot: | GP20HL |

| 5 | Tipo de corte: | Agua pura (solo agua) |

| 6 | Aplicación: | Corte de materiales compuestos |

| 7 | Tipo de bomba: | SCREAMLINE SL-VI (100HP) |

| 8 | Dispositivos que incluyen: | Brazo robótico, mesa de corte, bomba intensificadora, enfriadora, etc. |

Ahora quiero mostrarte esta solución de corte por chorro de agua robot:

Puede ver en nuestras imágenes que esta estación de trabajo de corte por chorro de agua robótica fue construida desde cero.

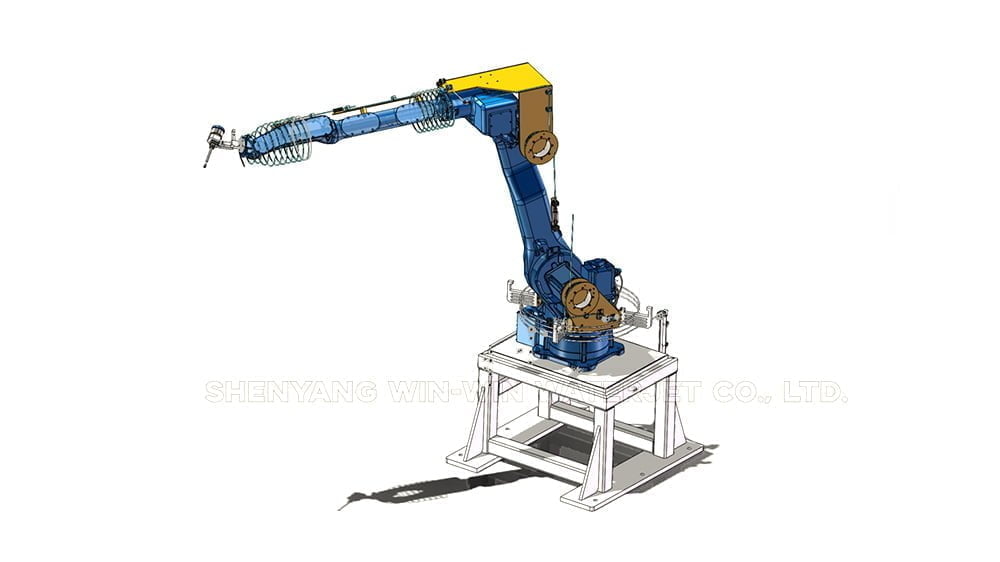

En el primer paso, podemos ver que esta es una representación de un brazo robótico con todas las bobinas, soportes, protectores y cabezales de corte y otros accesorios de alto voltaje, bases. Este es el plan que hemos decidido después de discusiones en profundidad con los compradores de estaciones de trabajo de chorro de agua robot, y luego las representaciones de diseño que hicimos.

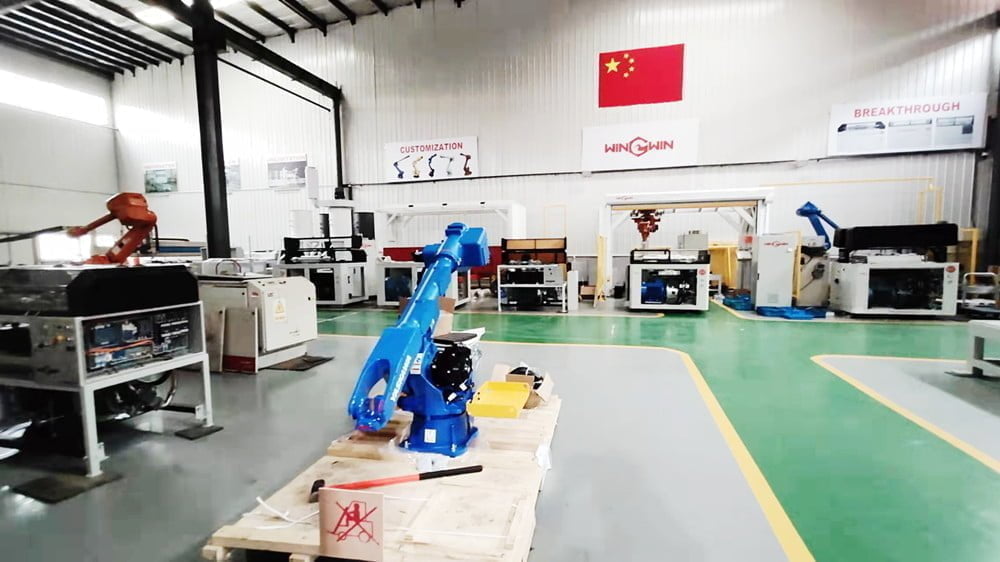

En el segundo paso, se ordena y entrega el brazo robótico. Todos los robots en la solución de chorro de agua robot son seleccionados de marcas de renombre mundial, con buena calidad, rendimiento estable, alta precisión, servicio postventa garantizado y garantía mundial. Los usuarios pueden elegir la marca que desean para la solución de corte por chorro de agua del robot, o dejarnos recomendarla.

El tercer paso es ensamblar la máquina de chorro de agua del robot, fijar el robot a la base, instalar todos los accesorios de alto voltaje correspondientes, colocar la plataforma de corte, conectar el sistema de control, la bomba de alta presión, el refrigerador, la máquina de adsorción de vacío, etc., todas las vías fluviales, circuitos y fuentes de aire esperan.

El tercer paso es depurar y probar la estación de trabajo de corte por chorro de agua del robot, depurar el rendimiento y los parámetros de la máquina para lograr el mejor estado y notificar al cliente para la inspección por video o la inspección de fábrica después de la finalización.

El cuarto paso es empaquetar y entregar las mercancías. Una vez que se completa la aceptación de todo el equipo, cada dispositivo se empaqueta y empaqueta cuidadosamente.

Estos procesos toman alrededor de 1-2 meses, diferentes soluciones de corte por chorro de agua de robots, diferentes configuraciones o diferentes marcas de robots para soluciones de corte por chorro de agua robot, el tiempo variará.

What’s the robot waterjet cutting system?

A robotic water jet cutting system is an automated system that utilizes robotics and water jet technology for cutting and processing. It combines the flexibility of industrial robots with the high precision and no heat effect of water jet cutting, and is used for cutting, engraving and processing of various materials in the field of manufacturing and processing.

A robotic waterjet cutting system usually consists of the following components:

Robot: The industrial robot is the core component of the system, capable of precise motion control in three-dimensional space. It can position the water jet cutting head to the position where it needs to be cut according to the program and instructions, and move according to the predetermined path. The robot arms suppliers we have cooperated with include ABB, Fanuc, Kuka, Yaskawa etc.

Waterjet Cutting Head: A waterjet cutting head is a robot-connected device that generates and controls a water jet. It usually includes components such as high-pressure water pumps, nozzles, mixing chambers and regulating devices. The water jet cutting head can generate high-speed water jet, and adjust the water pressure, flow rate and nozzle diameter and other parameters according to the needs.

Control system: The robotic waterjet cutting system is equipped with a dedicated control system for programming and controlling the movement of the robot, as well as adjusting and monitoring the parameters of the waterjet. Control systems usually include programming software, motion controllers, sensors, and monitoring equipment.

The working principle of the robotic water jet cutting system is to accurately position the water jet cutting head to the part that needs to be cut by controlling the trajectory and speed of the robot through programming. At the same time, the control system will adjust the pressure and flow of the water jet to adapt to different materials and cutting requirements. Waterjet cuts or processes materials into desired shapes and sizes through high-speed jetting and shearing action.

Robotic water jet cutting system has the following advantages:

High precision: Water jet cutting can achieve high-precision cutting and processing, and can meet the requirements of complex shapes and details.

No heat impact: Since water jet cutting is a non-thermal cutting process, there will be no problems such as heat affected zone, discoloration or deformation, and it is suitable for various sensitive materials.

Multi-material suitability: Robotic waterjet cutting systems can handle a wide variety of materials, including metals, composites, plastics, stone, and more.

Automation and flexibility: Robot operation and programming can achieve automation and flexibility to adapt to different products and batch production needs.

Robotic water jet cutting systems are widely used in automobile manufacturing, aerospace, shipbuilding, architectural decoration and other fields, providing efficient, accurate and reliable cutting solutions for the production process.

How long does it take for a set of robot waterjet cutting equipment from design to shipping?

Which car parts can the robot waterjet cutting system cut?

Robot waterjet cutting technology can be applied to the cutting and processing of various materials in the interior and exterior of automobiles. The following is a list of some common automotive interior and exterior materials, which are suitable for robotic waterjet cutting:

plastic:

ABS (acrylonitrile-butadiene-styrene copolymer)

PC (polycarbonate)

PP (polypropylene)

PVC (polyvinyl chloride)

PE (polyethylene)

Fabrics and Textiles:

car seat fabric

roof fabric

Carpets and Flooring Materials

door trim fabric

leather:

seat leather

steering wheel leather

Door interior leather

center console leather

Wood and wood composites:

wooden decorative panel

wood floor trim

Wooden center console trim

Foam and padding materials:

Foam padding for seat and backrest

Foam padding for ceiling and door trim

Audio Soundproofing Material:

Audio Soundproofing Liner

soundproofing material covering

It should be noted that robotic water cutting technology is suitable for most non-metallic materials, including rigid materials and flexible materials. It can achieve high-precision cutting and processing without thermal impact, and is suitable for interior and exterior trims with complex shapes and detail requirements. However, for some special materials or specific cutting requirements, further evaluation and testing may be required to determine the suitability of robotic waterjet cutting.

How do you ship the robot waterjet cutting system?

Our robot waterjet cutting system usually uses a 20-foot container or a 40-foot container. All large pieces of equipment are packed with soft film, and the outer layer is fixed with straps, and small pieces are packed into plywood. wooden box. We provide overseas on-site installation and commissioning work, including equipment training, please contact us for details.

1. Es una bomba de gran caudal, y su caudal máximo puede alcanzar 7.6L / MIN, lo que significa que su eficiencia de corte es mayor que la de las bombas de flujo ordinarias; y puede conducir simultáneamente seis orificios de 0,17 mm Los cabezales de corte trabajan simultáneamente. La ventaja de esta función es que una bomba puede suministrar 6 brazos robóticos para trabajar al mismo tiempo, lo que ahorrará costos y mejorará la eficiencia de la producción. Es una bomba muy popular en la industria de corte de interiores automotrices.

2. The intensifier of this waterjet pump can be single or dual in the robot waterjet cutting solutions or other waterjet cutting applications. Customers can request to bring two intensifiers when purchasing, or add one after use. Then under what circumstances do you want to buy a pump with double intensifiers, or under what circumstances do you want to add one? The advantage of the double intensifier structure is that it can truly work 24 hours without stopping. When one of the intensifiers of the pump is in the situation of dismantling and repairing, we can switch to another intensifier to work. It is very beneficial for the processing industry with high efficiency requirements, heavy workload or deadlines.

If you are interested in our robot waterjet or intensifier pump, contact us please.

You can tell the industry you are in, the material you need to cut, we have rich experience in robot waterjet cutting, we have done cases in various industries, we can put forward very constructive suggestions and solutions of robot waterjet cutting for you.

Si desea utilizar el robot de chorro de agua en algunas industrias usadas o de corte de materiales relativamente poco comunes o poco comunes, también nos complace investigar para usted, porque tenemos un equipo de investigación y desarrollo técnico sólido y profesional.

We will update our latest product solutions on YouTube (en inglés) channel, you can follow our account to get our latest industry-related consultation.