Descripción

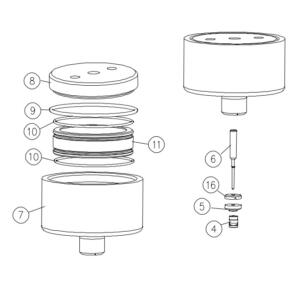

Waterjet spare parts: Socket head screw

Item number: 95119012

DetalleS: utilizado en la máquina de corte por chorro de agua SL-VI 100HP

Piezas de chorro de agua relacionadas:

| Número de artículo | Descripción |

| 80079668 | waterjet spare parts Bulkhead pipe assembly |

| 05141569 | piezas de repuesto de chorro de agua Montaje de bastidor |

| 10097657 | piezas de repuesto de chorro de agua Tornillo de cabeza de botón 1/4-20×3/4 |

| 95391322 | piezas de repuesto de chorro de agua Lavadora plana .25 |

FAQ of platform waterjet machine & waterjet spare parts etc.:

When using a waterjet cutting machine, it is generally not necessary to punch holes in advance. Waterjet cutting is a versatile and precise method that can cut through a wide range of materials, including metal, plastic, and composites, without the need for hole punching.The high-pressure waterjet stream is capable of piercing through the material at the starting point of the cut. The waterjet is focused and concentrated, allowing it to create an initial hole or pierce the material directly. Once the initial hole is created, the waterjet cutting machine can continue along the programmed cutting path.However, there may be instances where hole punching or drilling pilot holes is beneficial, depending on the specific circumstances:Thick or Tough Materials: For very thick or exceptionally hard materials, it may be helpful to use a drill or hole punch to create a starter hole. This can facilitate the initial piercing and ensure smoother cutting.Delicate Materials: In some cases, when working with delicate materials that are prone to cracking or chipping, creating a pilot hole or using a drill bit with a smaller diameter can help minimize the risk of damage during the piercing process.Precision Alignment: If precise hole placement is required, it may be beneficial to drill pilot holes beforehand to ensure accurate alignment with the waterjet cutting path.It’s important to consult with waterjet machine manufacturers or experienced operators to determine the best approach for your specific material and cutting requirements. They can provide guidance on whether hole punching or drilling pilot holes is necessary or beneficial for your particular application.Always prioritize safety when operating a waterjet cutting machine, and follow the manufacturer’s recommendations and guidelines for safe and efficient use.

Necesita soporte técnico o piezas de chorro de agua, contáctenos en WhatsApp o déjenos un mensaje.