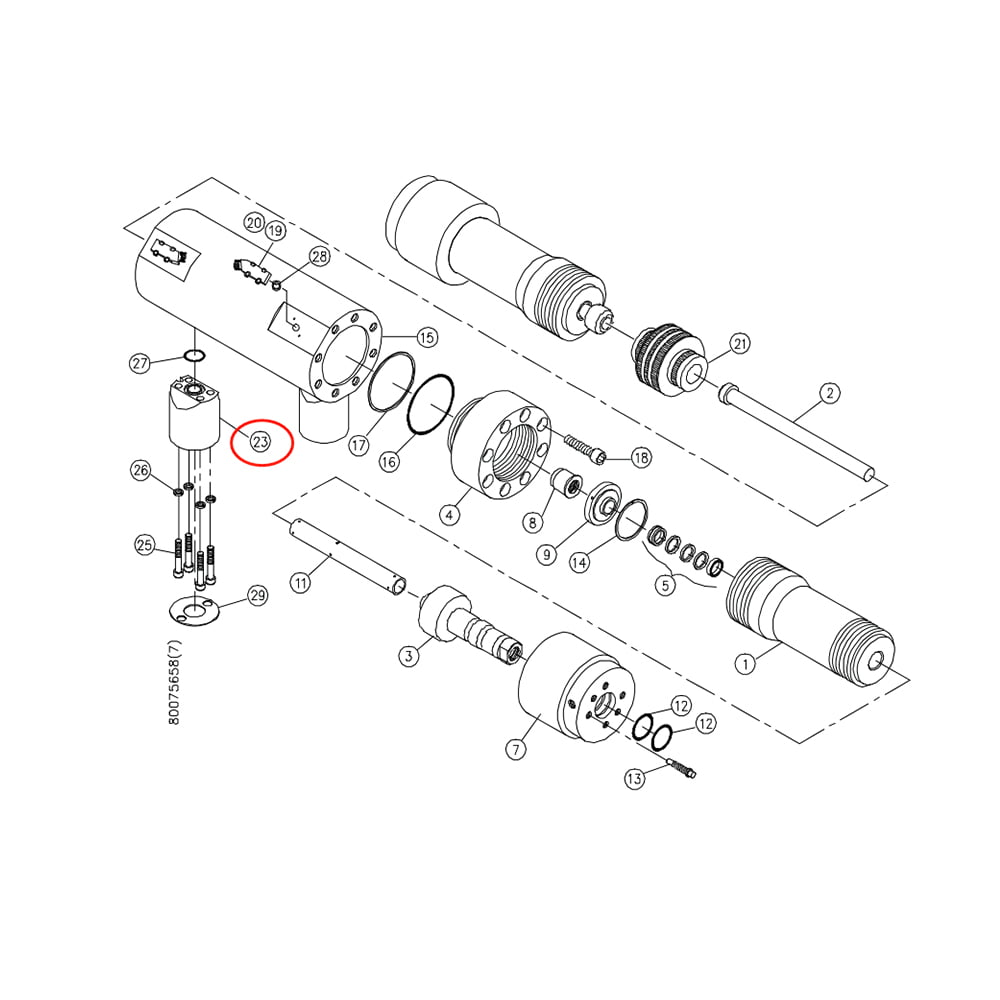

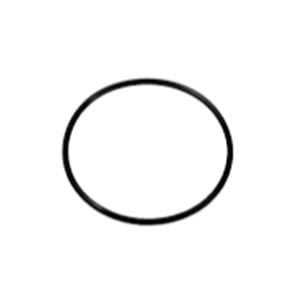

Descripción

Waterjet spare parts: Topworks support

Item number: 05144522

DetalleS: utilizado en la máquina de corte por chorro de agua SL-VI 100HP

Piezas de chorro de agua relacionadas:

| Número de artículo | Descripción |

| 80079668 | waterjet spare parts Bulkhead pipe assembly |

| 05141569 | piezas de repuesto de chorro de agua Montaje de bastidor |

| 10097657 | piezas de repuesto de chorro de agua Tornillo de cabeza de botón 1/4-20×3/4 |

| 95391322 | piezas de repuesto de chorro de agua Lavadora plana .25 |

FAQ of platform waterjet machine & waterjet spare parts etc.:

Water quality is an important consideration when using a waterjet cutting machine. The quality of the water can affect the performance, reliability, and maintenance of the machine. Here are some key requirements for water quality when using a waterjet cutting machine:Clean and Filtered Water: The water used in a waterjet cutting machine should be clean and free from impurities that could clog or damage the system. It is recommended to use water that has undergone filtration to remove particles, sediments, and contaminants. Filtration systems may include filters, strainers, or settling tanks. Low Levels of Minerals and Solids: The water should have low levels of minerals and solids, such as calcium, magnesium, iron, and silica. High mineral content can lead to scale formation, nozzle blockages, and reduced cutting performance. Water softening or conditioning systems may be required to reduce mineral content. Low Total Dissolved Solids (TDS): TDS refers to the concentration of dissolved substances in water. A high TDS level can lead to issues like nozzle clogging, reduced cutting speed, and increased maintenance. It is generally recommended to maintain a TDS level below a certain threshold, which may vary depending on the specific waterjet cutting machine and manufacturer’s recommendations. No Oils or Chemical Contaminants: The water used in a waterjet cutting machine should be free from oils, greases, or chemical contaminants. These substances can affect the performance of seals, valves, and other components in the system. Proper filtration and regular maintenance of the water treatment system can help ensure the absence of such contaminants. Adequate Water Pressure and Flow: The water supply should provide sufficient pressure and flow rate to meet the requirements of the waterjet cutting machine. The machine’s specifications will indicate the minimum water pressure and flow rate needed for optimal operation. Some waterjet cutting machine manufacturers may provide guidelines or offer specific water treatment systems to maintain the required water quality. Consulting the waterjet cutting machine manufacturer or a water treatment specialist can provide further guidance on the specific water quality requirements for your machine and how to achieve and maintain them effectively.

Necesita soporte técnico o piezas de chorro de agua, contáctenos en WhatsApp o déjenos un mensaje.