Descripción

Win-Win es el fabricante de chorro de agua para estaciones de trabajo robotizadas, máquinas de corte por chorro de agua y piezas de repuesto, etc.

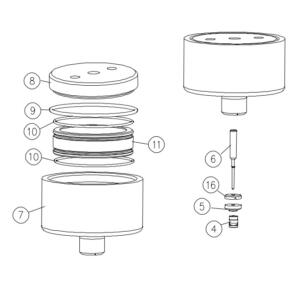

Part Name: waterjet hp tube

Item number: 10069326

DetalleS: utilizado en la máquina de corte por chorro de agua SL-VI 100HP

Relacionado Piezas de chorro de agua:

| Número de artículo | Descripción |

| 05051214 | Fabricante de chorro de agua Conjunto de manguera hidráulica .25 x 39.0 |

| 80079809 | Fabricante de chorro de agua Adaptador 1.0 x .75 |

| 80079536 | Fabricante de chorro de agua Conjunto de manguera hidráulica 1.0 x 36.0 |

| 80085889 | Fabricante de chorro de agua Conjunto de manguera hidráulica .25 x 20.0 |

| 05061163 | Fabricante de chorro de agua Conjunto de manguera hidráulica .75 x 31.0 |

FAQ of platform waterjet machine & waterjet spare parts etc.:

Creating border swirls on marble tiles using a waterjet cutter can be a visually appealing addition to a dining room. Here’s a general guide on how you could achieve this:Design and Planning: Start by designing the desired border swirl pattern on the marble tiles. Use computer-aided design (CAD) software to create the pattern or hire a professional designer to assist you. Consider the size, shape, and placement of the swirls to complement the dining room’s aesthetics.Material Preparation: Acquire the marble tiles with the appropriate dimensions and thickness for the project. Ensure the tiles are clean, dry, and free from any debris or surface imperfections before beginning the cutting process.Waterjet Cutting Setup: Set up the waterjet cutting machine according to the manufacturer’s instructions. Ensure the machine is calibrated and properly configured for cutting marble. Connect the abrasive delivery system and check for any leaks or malfunctions.Pattern Transfer: Transfer the designed swirl pattern onto the marble tiles using a stencil or transfer paper. Secure the stencil firmly on the tile surface to prevent movement during the cutting process.Cutting Process: Place the marble tiles on the cutting table and align them accurately with the waterjet machine’s cutting path. Initiate the cutting process, and the waterjet cutter will follow the pattern outlined on the stencil, precisely cutting the swirls into the marble tiles.Finishing and Cleaning: Once the cutting is complete, remove the cut tiles from the machine and carefully detach the stencil or transfer paper. Inspect the swirl cuts for any imperfections or rough edges. Use sandpaper or a polishing tool to smooth and refine the edges if necessary.Installation: Install the marble tiles with the border swirls in the desired location within the dining room. Ensure they are properly aligned and secured to create a seamless and visually appealing border.

Necesita soporte técnico o piezas de chorro de agua, contáctenos en WhatsApp o déjenos un mensaje.