Descripción

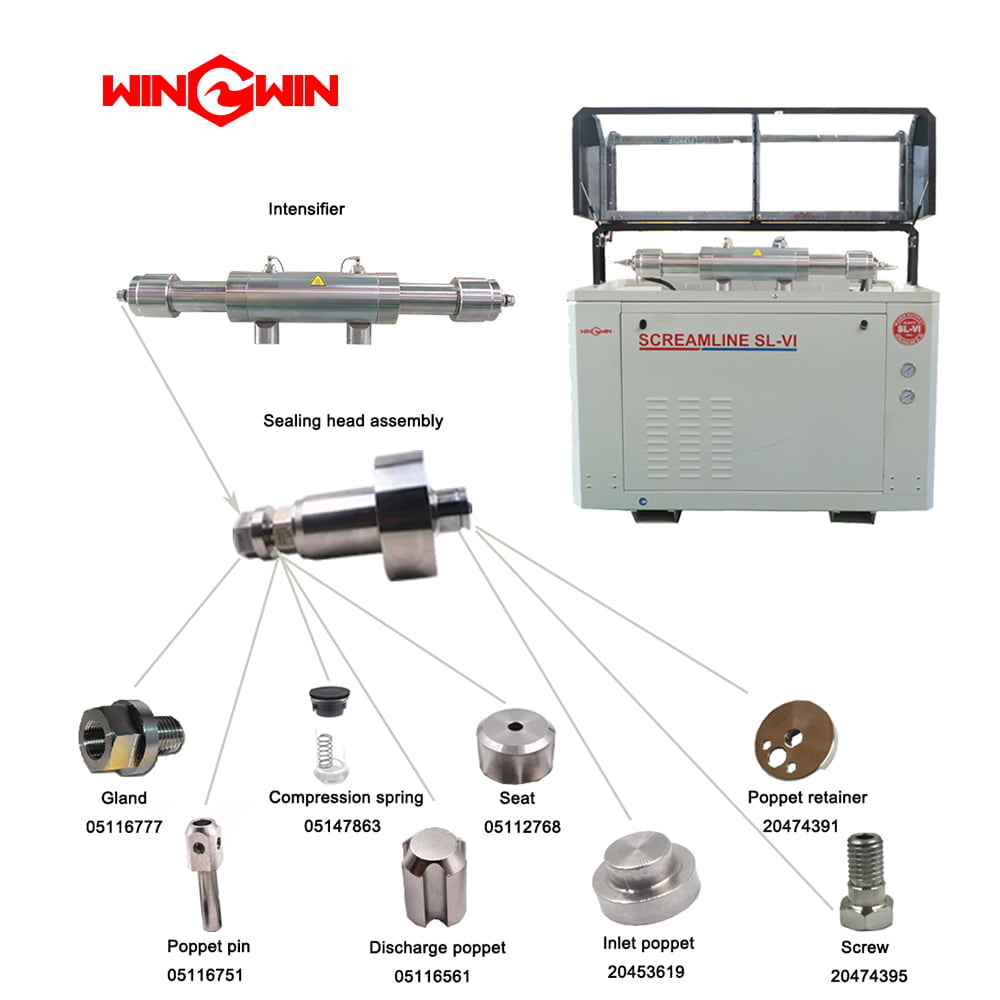

Waterjet Machine Parts Item Number: 20428052

Application: both water jet cutting head and water jet intensifier pump

The next picture shows the installation position of our waterjet machine parts seal assembly:

You can see that the installation positions of our sealing assembly in the two pictures are the same, but the types of these two pneumatic valves are different. One is normally open and the other is normally closed. Generally speaking, normally open pneumatic valve is used for intensifier pump, for unloading valve assembly, when the machine stops working when the cylinder is open, automatic pressure relief; And another normally closed pneumatic valve is usually installed on the cutting head of the waterjet cutting machine, so that when the machine begins to work to give an air pressure, the cylinder will begin to vent for cutting work.

Normally the water jet seal assembly was sold by set with other waterjet machine parts, such as the 20435636 valve stem, 10188233 backup ring brass, 10178697 valve seat and also the 10187250 backup ring (stainless steel).

We continue to share about waterjet cutting machine maintenance, possible failure causes and waterjet machine parts:

We often receive questions from our waterjet cutting machine users about waterjet mixing tube blockage. If you have encountered similar problems, please read our article carefully:

1. If you have adjusted the abrasive garnet transport volume recently, it may be that the water jet abrasive flow is too large, leading to the mixing tube blockage

2. If you have recently changed the specification of the abrasive garnet, or the aperture size of the mixing tube used, the blockage may be caused by too large abrasive particles

3. The dust content in the abrasive is too much, the dust will encounter water and be affected by moisture, resulting in the abrasive is easy to consolidate into clusters, the diameter of these clusters is larger than the diameter of the mixing tube, when they are transported to the mixing tube, it is easy to produce the phenomenon of blockage

4. The aperture of the mixing tube and the water jet nozzle do not match. Usually, the ratio of the nozzle to the mixing tube is better than 1:3

5. Abrasive in the process of use mixed with other large particles of impurities, you need to do a good job of abrasive storage to avoid mixing impurities.

If the above problems have been checked and the cause has not been found, you can check whether the water jet abrasive tank is not cleaned in place. There may be impurities mixed with it or the welding waste will fall off