Descripción

Carcasa de filtro XG19 / 220 con pieza de máquina de corte por chorro de agua R3-4 BSP

Knowledge for portable gas pipe waterjet cutting and waterjet Cutting machine part:

Before you want to buy a portable water jet cutting machine, we need to know the following specific information:

1- Cutting material, choose explosion-proof, trolley type,

Permanent magnet trolley, track trolley, chained, inner cut, outer cut.

Pneumatic and electric dual-purpose – gas drive, electric drive.

2-Waterjet Ccutting machine part High pressure pipe

3-Cooling-Water Tower/Water Chiller

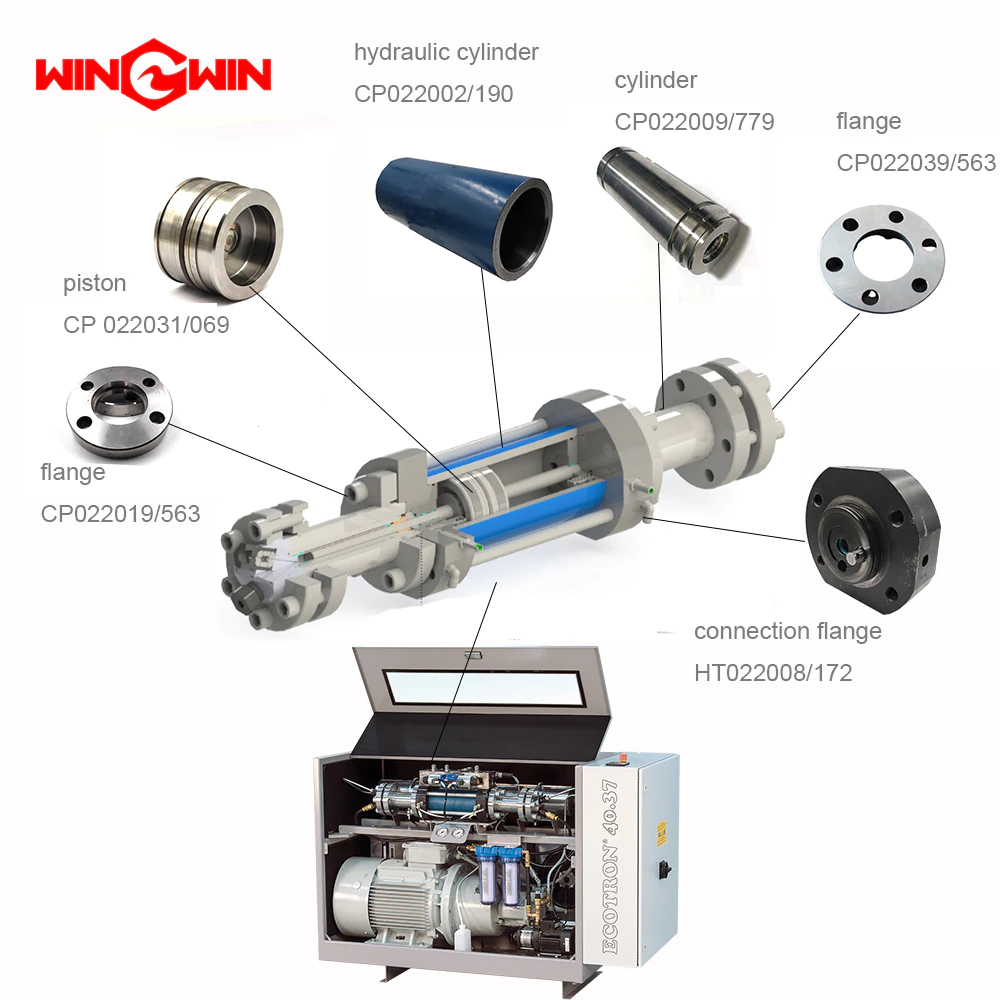

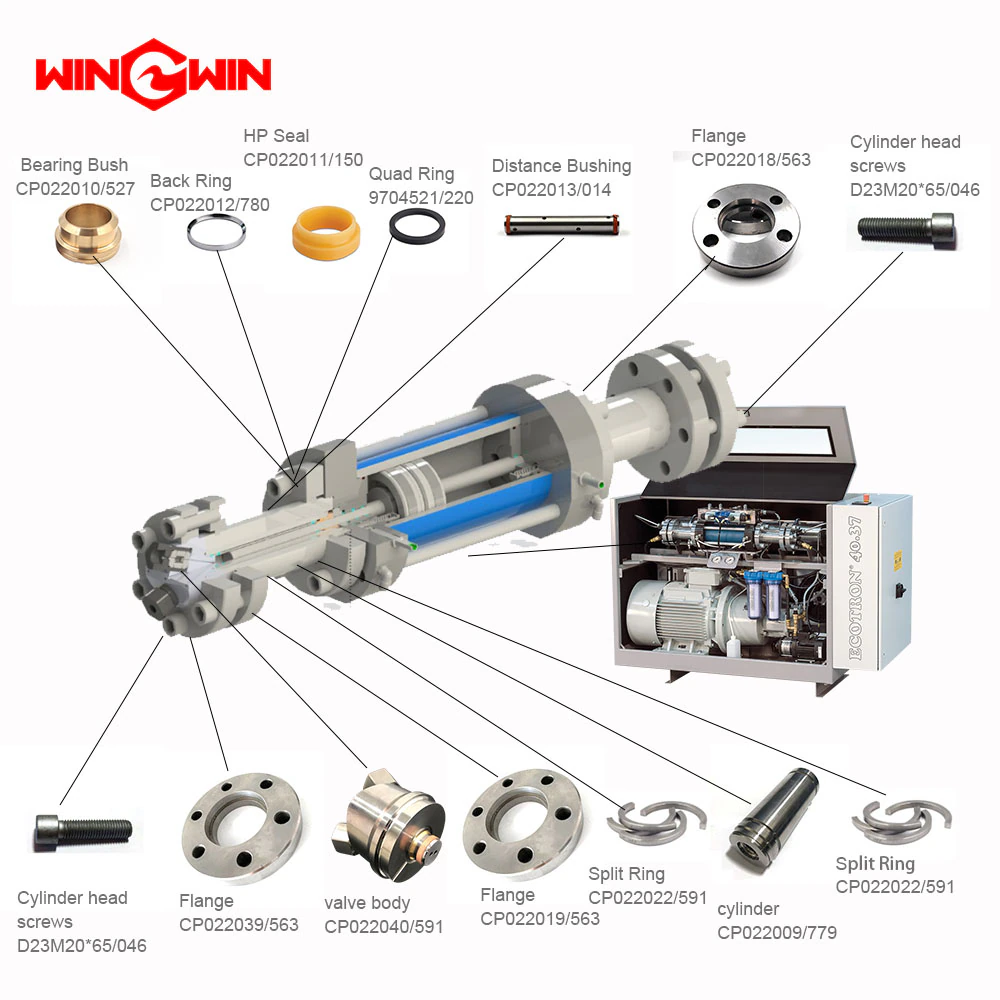

4-cutter head, high pressure pump

5- Handheld, short car

6-Abrasive supply system

7. Abrasive mixing type

Standard Portable Waterjet

1. High pressure pump 1

2. Waterjet Cutting machine part High pressure pipe/high pressure hose 7 meters

3. Portable car 1

4. Chain guide (10m)/track (2m) or others

5. Sand supply tank Sand control valve 1 set

6. Refrigerator/chiller 1

7. Waterjet Cutting machine part Cutting head

8. Waterjet Cutting machine part 90 degree swivel joint

Shipping volume — standard configuration, net weight 1280 kg, gross weight 1310 kg. Volume about 5

cubic meter

There are two boxes:

190x110x200cm, 72x80x130cm

Optional portable cutting solutions for customers:

1: Select several types of cars according to customer requirements, and determine which type of car

2: Products cut by customers, such as: oil pipes, chemical pipelines, etc., according to the cutting products provided by customers, we have certain experience to discuss

3: You can choose explosion-proof pump

4: Choose the mode of the cutting trolley: the trolley has permanent magnet type + guide rail type/chain type. We also have a dual-purpose trolley for moving and cutting with a hand-held cutter head. For this part, we also have a trolley that uses gas and electricity alone. Connect the high-pressure pipe fittings of the trolley to confirm the relevant components of the high-pressure pipe assembly of the cutter head high-pressure pump according to the pressure of the pump

5: High configuration refrigerant cooling system