Descripción

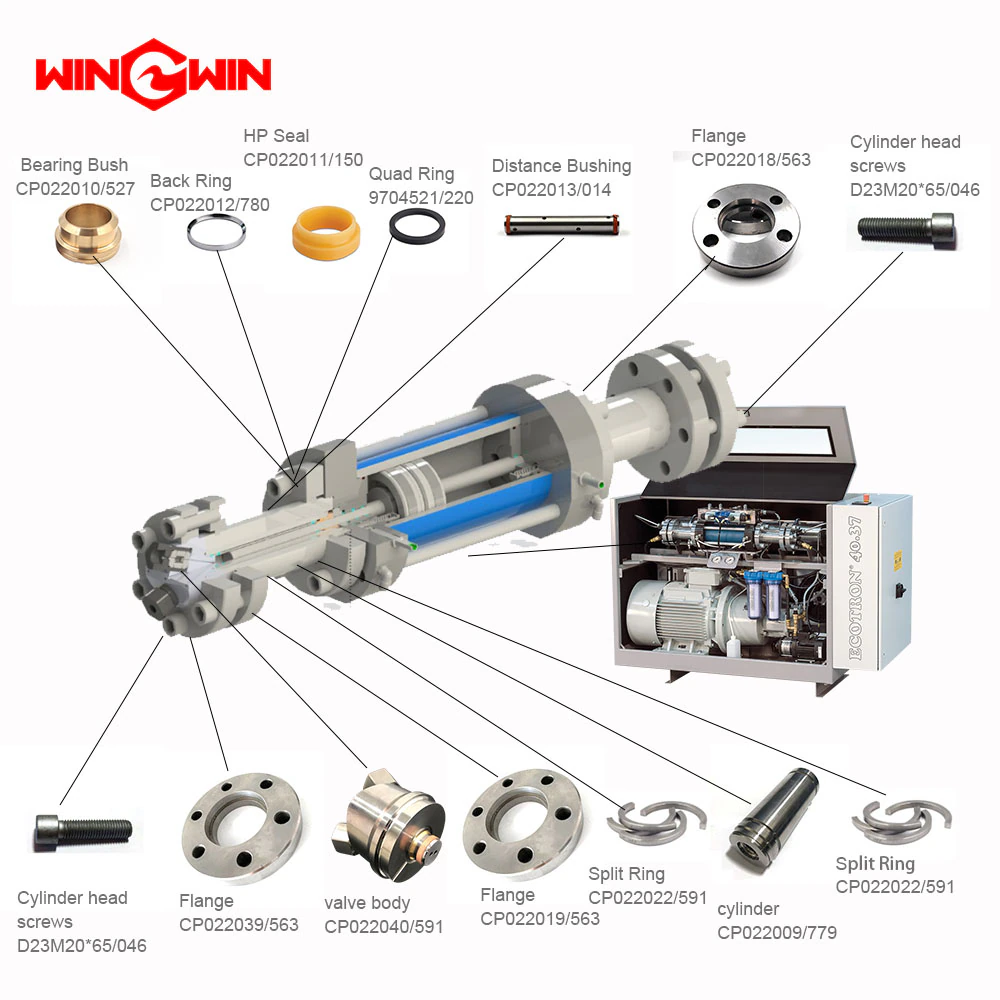

CP022013/014 Parte de la máquina de corte por chorro de agua de buje de distancia

Knowledge for Waterjet Cutting Machine and Waterjet Cutting Machine Part:

1: Water jet cutting equipment and Waterjet Cutting Machine Partfeatures introduced:

1、 CNC forming of various complex patterns;

2, cold cutting, no thermal deformation or thermal effects;

3, environmental protection, no pollution, no toxic gas and dust;

4, can process a variety of high hardness materials, such as: glass, ceramics, stainless steel, or softer materials, such as: leather, rubber, paper diapers, etc.

such as: leather, rubber, paper diapers, etc.;

5, Waterjet Cutting Machine Part is some composite materials, fragile porcelain material complex processing of the only means;

6, smooth cut, no slag, do not need secondary processing;

7, can complete the drilling, cutting, forming work in one time;

8、 Low production cost;

9、 High degree of automation;

10, 24 hours continuous work.

In order to better reduce costs, engineers and manufacturers continue to explore, and now water jet cutting can be very effective in reducing costs to create greater profits. Therefore, it is necessary to learn more about the application of waterjet technology to use the lowest cutting costs to create greater profits.

In terms of cutting costs, the water jet cutting industry is considered to be the most versatile and fast growing industry. In addition to the above, water jet cutting is currently one of the most productive machines in the world, which is superior to other processing technologies such as flame cutting, plasma processing, laser processing, EDM processing, turning, milling and planing. At the same time, waterjet cutting does not produce harmful gases or liquids, does not generate heat on the surface of the workpiece, it is truly versatile, efficient and cold cutting processing.

Water jet cutting demonstrates that it can do some processing that cannot be done by other simple processes. It can punch holes in titanium, and can cut various patterns in stone or glass, all of which show the uniqueness of waterjet itself. It produces no heat when cutting materials, and during this cold processing, it produces supersonic water arrows that can achieve ideal results when shot at the surface of the cutting material, and the mixture of water and abrasive enhances its cutting ability even more.