Descripción

Waterjet accessories Abrasive waterjet cutting nozzles, orifices

| Inner Diameter | Número de artículo | |

| Orificio | 0.20mm | 1004309 |

| 0.25mm | 1004273 | |

| 0.30mm | 1004274 | |

| 0.35mm | 1004275 | |

| 0.40mm | 1004271 | |

| Nozzle | 0.76mm | 1004240 |

| 1.02mm | 1004239 |

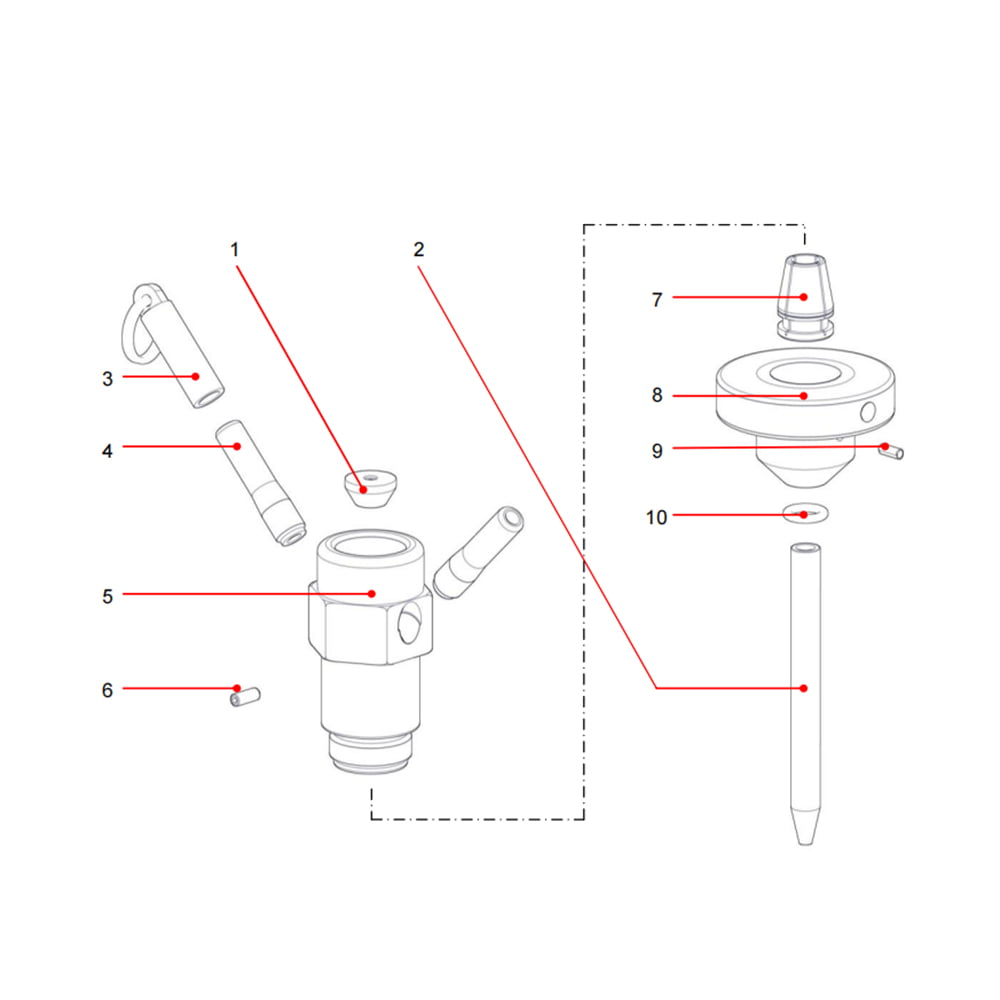

Related waterjet accessories of the abrasive cutting head assembly:

| Número de artículo | Descripción |

| 1005325 | Cap abrasive inlet tube |

| 1004581 | Abrasive inlet tube |

| 1049513 | Mixing chamber |

| 1001870 | Adjustment screw |

| 1052196 | Collet |

| 1004368 | Clamping nut |

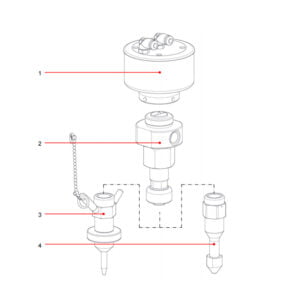

Other related waterjet accessories:

| 1027347 | Cuerpo de la válvula |

| 1004604 | Conjunto de válvula de retención |

| 1003551 | Pistón hidráulico |

| 1003544 | Cilindro hidráulico |

| 1003644 | Carcasa del filtro |

| 1003433 | Adaptador de válvula de retención |

| 1004146 | Cilindro hidráulico |

| 1001653 | Anillo de sellado de alta presión |

| 1009700 | Acoplamiento |

| 1003302 | Filtro de alta presión |

| 1004541 | Kit de reparación de válvulas de retención |

| 1004386 | Anillo de retención del pistón |

FAQ of waterjet cutting machine & waterjet accessories: How to choose the appropriate waterjet mixing tube and waterjet orifice hole diameter?

First of all, we need to know that the inner diameter of waterjet mixing tube and waterjet orifice will affect the cutting speed and cutting accuracy of waterjet cutting machine, so it is also very important to choose a suitable orifice and mixing tube. Generally, waterjet manufacturers with water cutting experience will Recommend suitable products according to the material and cutting effect that the customer wants to cut.

1. The inner diameter of the waterjet orifice affects the overall cutting speed. Generally, a nozzle with a relatively small inner diameter usually leads to a slower cutting speed, but the relative cutting accuracy is indeed high, and the surface of the cut object will be smoother. On the contrary, the orifice has a larger inner diameter, and the cutting speed is relatively fast but the cutting surface is relatively rough. Because the water flow produced by orifice with small inner diameter will be thinner and the cutting time will be longer. In contrast, the water flow produced by orifice with large diameter will be relatively thicker, and the cutting gap will be larger.

2. The inner diameter of the waterjet mixing tube will also affect the cutting speed and precision. Because the mixing tube is the place where the abrasive garnet and the ultra-high pressure water are mixed to generate cutting force. Generally, a smaller waterjet mixing tube will produce a higher pressure mixed water stream, which can produce higher precision cutting. But mixing tubes with smaller bores also wear out faster and require more frequent replacement.

To sum up, the inner diameter of mixing tube and orifice needs professional advice from experienced personnel to determine