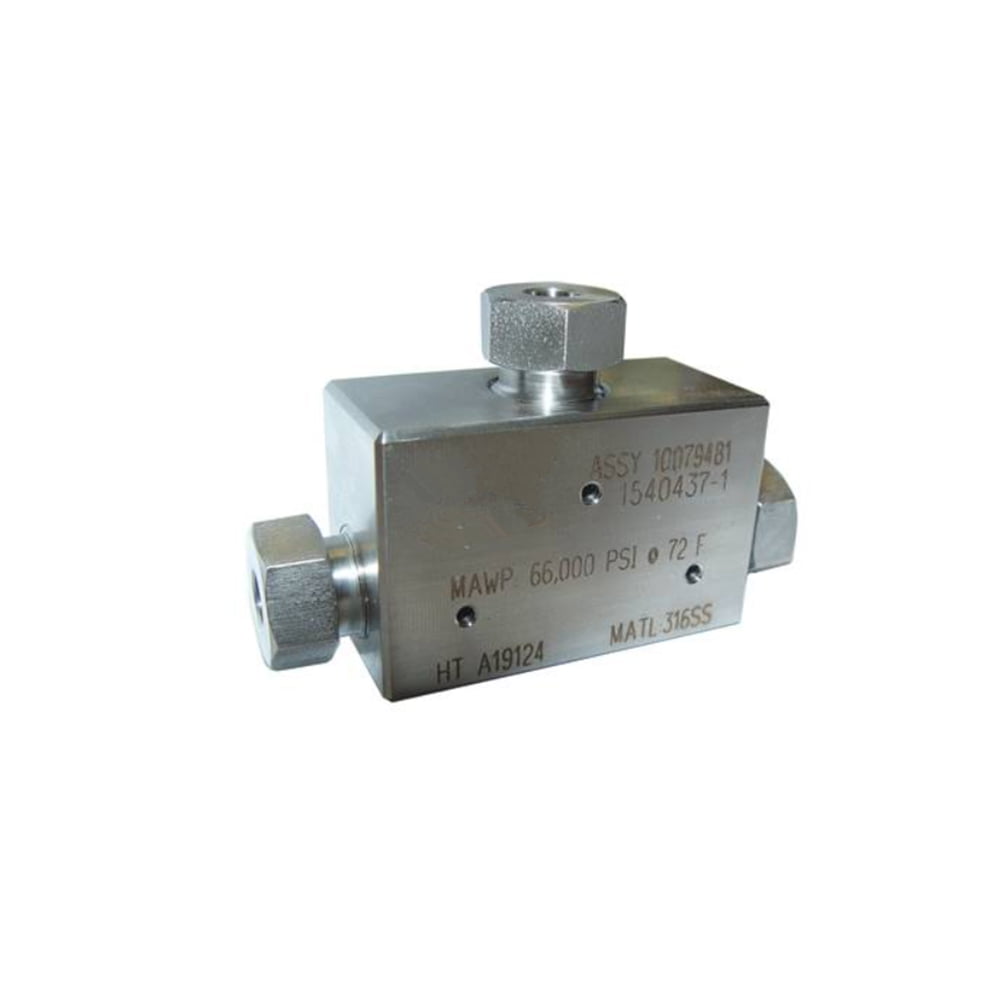

Descripción

49830599 ACOPLAMIENTO HP TEE 9/16 X 3/8" intensificador de chorro de agua

Piezas principales para la bomba SL-IV 50HP:

| Artículo | Producto NO. | Nombre del producto | Imagen |

| 1 | 05144647 | Cilindro HP |  |

| 2 | 05144688 | Conjunto de cabezal de sellado |  |

| 3 | 05144696 | Espaciador de cabezal de sellado |  |

| 4 | 05144712 | Camisa del cilindro |  |

| 5 | 05149703 | Conjunto de sellos |  |

| 6 | 05130091 | Cartucho hidráulico |  |

| 7 | 05119151 | Émbolo cerámico |  |

| 8 | 05116561 | Poppet HP |  |

| 9 | 05116751 | Pin de poppet |  |

| 10 | 05144670 | Retenedor de poppet |  |

Conocimiento para Máquina de corte por chorro de agua , Piezas de repuesto de chorro de agua y Piezas del intensificador de chorro de agua.

How to control the accuracy of rotary platform cutting of water jet robot workstation?

To control the accuracy of rotary platform cutting of water jet robot workstation, the following measures can be taken:

Accurate rotary platform design: ensure that the rotary platform structure is strong, stable and has sufficient rigidity. This will help reduce vibration and oscillation and provide more precise cutting control. (waterjet intensifier parts)

High-precision control system: Use a high-precision control system to control the motion of the rotary stage. For example, using precision position sensors and closed-loop control algorithms, the position of the rotary platform can be monitored and adjusted in real time to ensure accurate cutting. (waterjet intensifier parts)

Cutting path planning: When designing the cutting path, the motion range of the rotary platform and the cutting requirements are taken into account. By reasonably planning the cutting path, it avoids excessive rotation angles and frequent direction changes to ensure smooth and precise cutting. (waterjet intensifier parts)

Cutting parameter optimization: Optimize the cutting parameters, such as water pressure, nozzle size, jet speed, etc., according to the actual cutting requirements and material properties. Find the best combination of cutting parameters through experimentation and adjustment of parameters to improve the precision and effect of cutting. (waterjet intensifier parts)

Regular maintenance and upkeep: Keeping the rotary platform and related components in good condition is the key to ensure cutting accuracy. Regularly clean, lubricate and inspect the rotary platform, and repair or replace worn or damaged parts in time to ensure the normal operation of the system and the stability of cutting accuracy. (waterjet intensifier parts)

The comprehensive application of the above measures can effectively improve the precision of the rotary platform cutting of the water jet robotic workstation and realize more accurate cutting operations. (waterjet intensifier parts)

Si está interesado en cualquier producto de chorro de agua de Win-Win Proveedor de chorro de agua, Contáctame por favor.

The below video shows our new waterjet robot cutting workstation: