Descripción

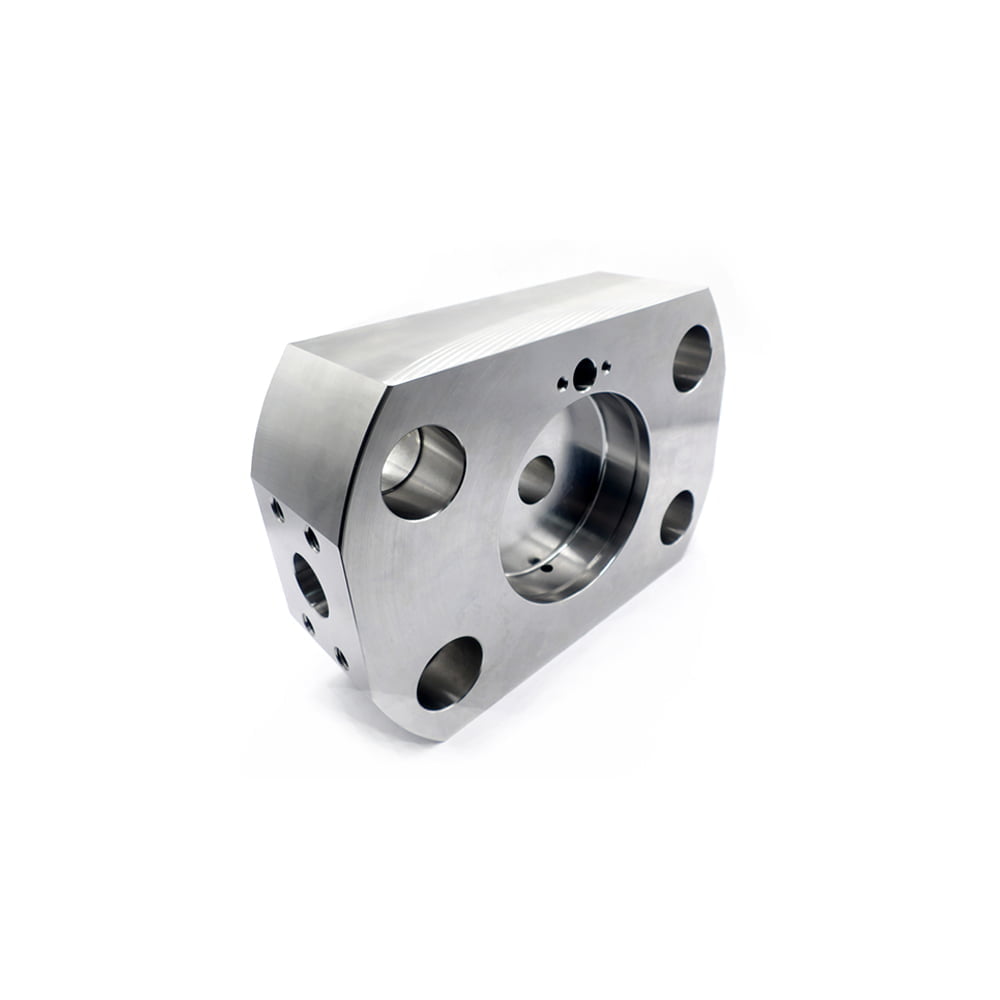

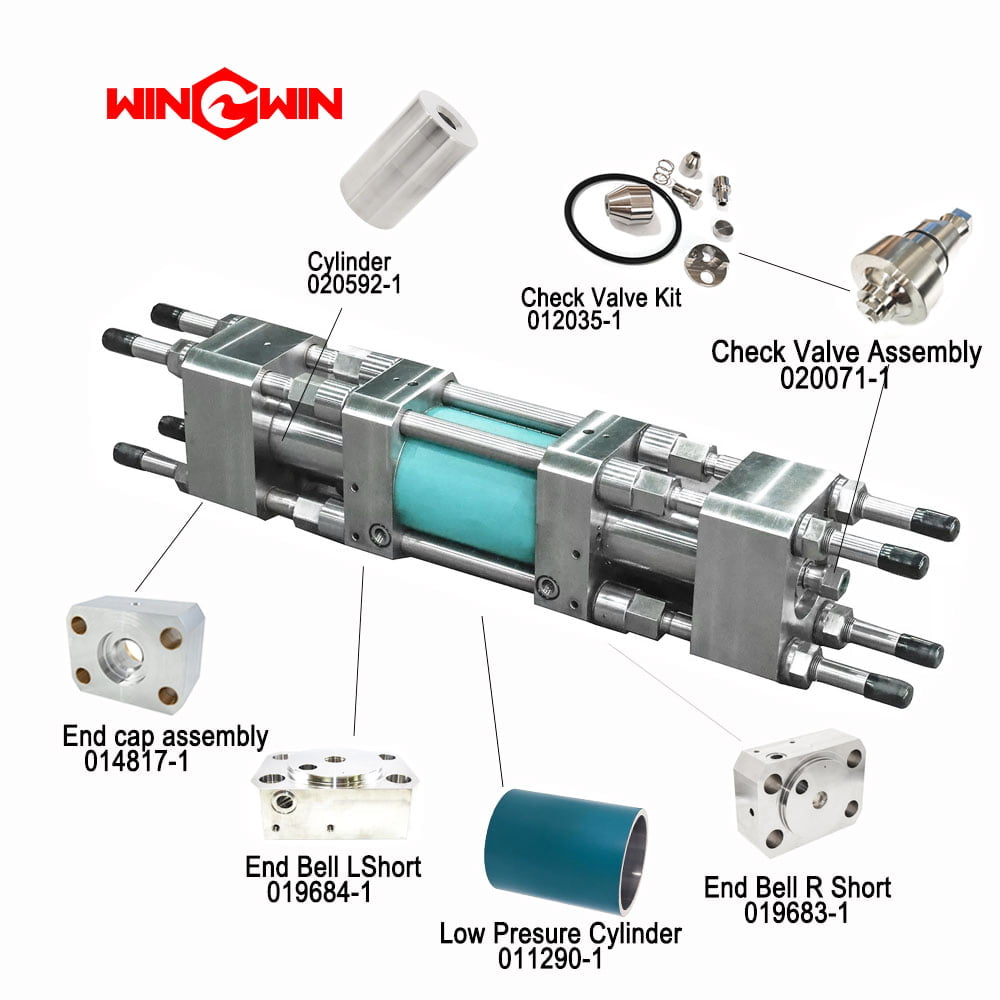

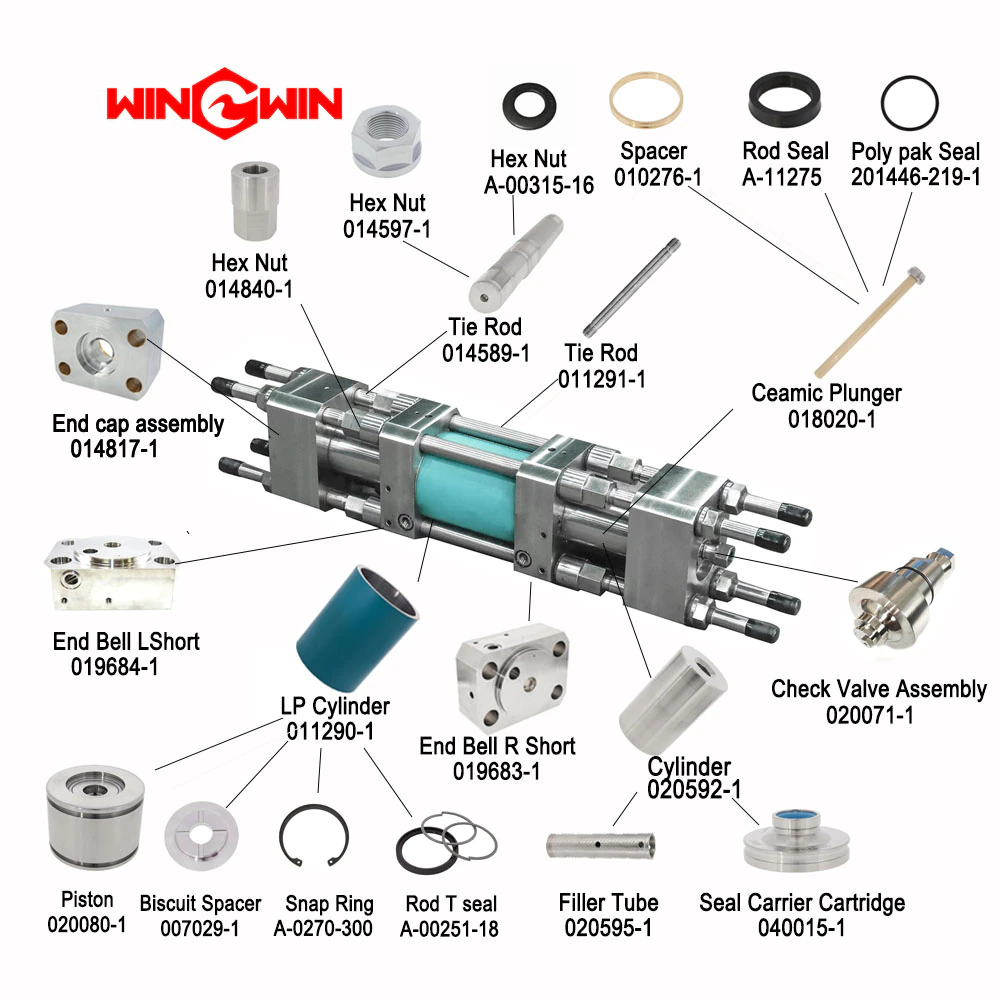

The water jet factory sell 019684-1 end bell assembly is used on 87k Psi high pressure intensifier pump, and with this item number, it’s left-hand one, we also have the right-hand end bell for your choice, you can check the following photo:

In water jet factory how to distinguish the 87k high pressure cylinder end bell about?

First, the difference is made according to the number. Each part of 87k intensifier pump has its own number. In many cases, the name may be repeated, but the part number will not be repeated, it’s unique for each water jet item. The water jet cutting machine users can confirm according to the part number, and can also describe according to the video and picture. The customer can describe the position of the end bell of the hydraulic cylinder and communicate with the water jet factory. Water jet factory can determine whether the customer needs 019683-1 End Bell Intensifier Right Hand or 019684-1 End Bell Intensifier Left Hand.

Please note: Some water jet intensifier pump’s hydraulic end bell is universal, some of them are not the same, it depends on the design of the water jet factory, we think that the left and right water jet end bell same is a reasonable design, but according to a lot of water jet factory design concepts and conditions, There will be different water jet intensifier pump structure, the 87K water jet pump structure is special, because the pressure of 87k intensifier pump is higher than the 60k water jet pump on the market, so from the structure and parts of the material have higher requirements, when the water jet users want to replace the water jet end bell, there are some suggestions that water jet factory technical staff put forward:

1: Find the damaged location of the water jet end bell and check whether it can be repaired.

2: It is very important to check whether the parts that fit with the water jet end bell are damaged. We once had a customer who confirmed that the hydraulic end bell was damaged. At the same time, they communicated with us Win-Win water jet factory and confirmed that the oil seal installation position of the right end bell was scratched. However, because the previous hydraulic end bell was damaged, there were scratches on the surface of the ceramic plunger, so after installing the new hydraulic end bell, the water jet intensifier pump still could not work normally, resulting in oil leakage. The customer soon bought a new ceramic plunger from the water jet factory for installation, and finally, this problem was solved perfectly. But it took a long time to do so. Time is cost. This reminds water jet factory that it has the responsibility and obligation to help customers diagnose the damage degree of parts and the problems existing in customers’ equipment. Water jet factory hopes to solve the problems for customers once and for all, so that the water jet cutting equipment can be put into production as soon as possible