Descripción

Piezas de repuesto de ABB Robotics

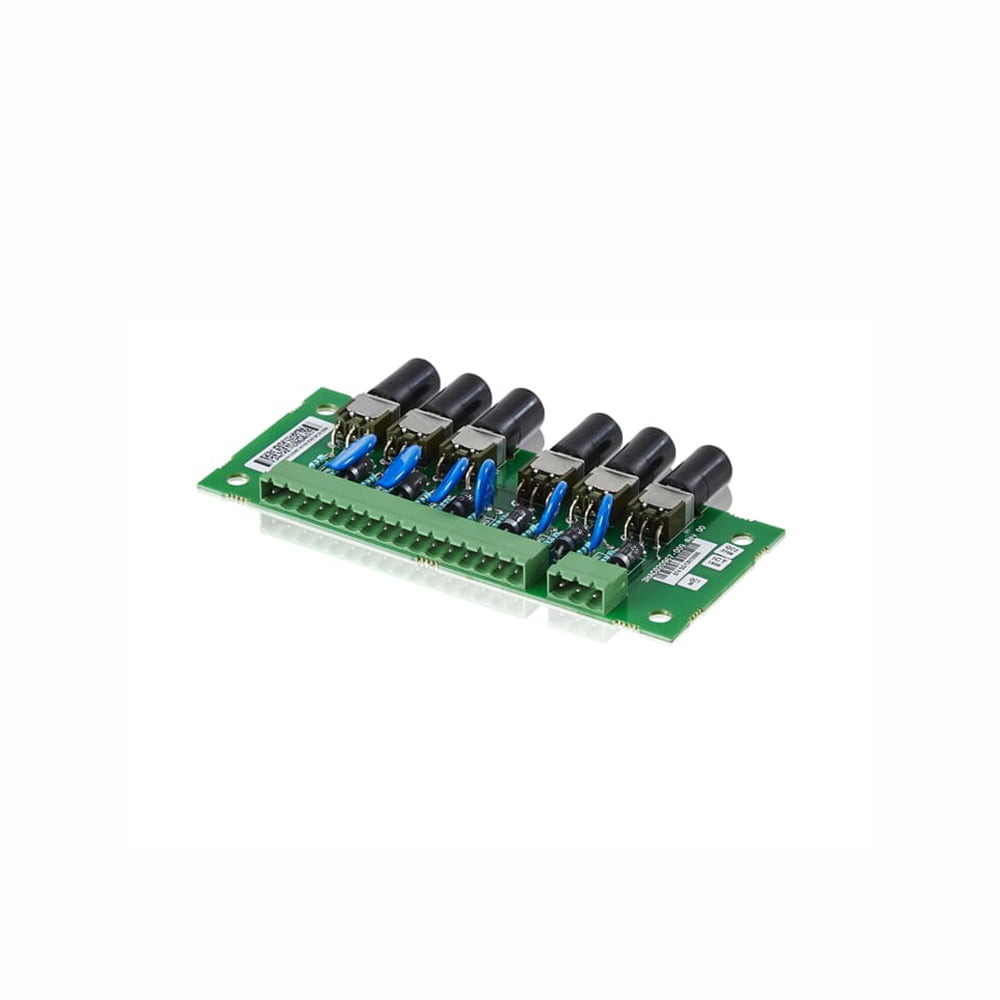

Item number: 3HAC020967-001 DSQC574

Item name: Push Button Unit

Detalles: utilizado en los brazos robóticos de ABB

Win-Win proporciona soluciones de chorro de agua robotizado, piezas de celdas de chorro de agua robotizadas, etc.

Related robot waterjet cutting workstation & Piezas de repuesto para robótica ABB:

Sistema robótico de corte por chorro de agua & Piezas de celdas de chorro de agua para robots: Estación de trabajo robótica de chorro de agua Yaskawa y piezas relacionadas, Estación de trabajo robótica de chorro de agua Fanuc y piezas relacionadas, Estación de trabajo robótica de chorro de agua ABB y Piezas de repuesto para robótica ABB.

FAQ of platform waterjet machine & robot waterjet system & ABB robotics spare parts:

Is there a correlation between the service life of a robot arm part and the production industry in which it is used?

Yes, there is a correlation between the service life of a robot arm’s parts and the industry in which it is used. Different industries may have different working environments, work intensities, and frequency of operation, all of which affect the wear and tear of the parts and their life expectancy. Here are a few considerations:

Work environment: Some industries have work environments that may place additional stress or wear on the robot arm’s parts. For example, some parts of a robot arm may be more susceptible to wear or deterioration when working in environments with high temperatures, high humidity, or corrosive chemicals.

Work Intensity: In high-productivity industries, robot arms may be required to work continuously, which can lead to accelerated wear on drive motors, joints, and other mechanical parts.

Work cycles: Frequent starts and stops, or repeated short cycle operations, can lead to premature wear of parts such as motors, gears and sensors.

Loads: If the robot arm is often required to carry heavy loads or perform high-precision operations, the joints and drive systems may be subjected to increased stress.

Application-specific: Water jet cutting or welding robots, for example, may face completely different wear and tear situations than other applications. Waterjets can cause rapid wear on the parts involved, while welding can cause high temperatures and sparks that can affect the robot’s housing and some of its parts.

Maintenance and calibration: Certain industries may have more stringent maintenance and calibration requirements, which can help extend the life of robot arm parts.

External disturbances: In some industries, robot arms may be exposed to external physical shocks or other disturbances that can shorten the life of parts.

Therefore, when selecting and maintaining a robot arm for a specific manufacturing industry, it is important to understand the specific needs and challenges of that industry. This will ensure the durability and stability of the robot arm, resulting in optimal performance and output.