Descripción

The Seal Assembly 05120118 is a component of hydraulic piston assembly used in the Bomba de chorro de agua de 90.000 psi.

The Seal Assembly is designed to provide a tight seal between the high-pressure components of hydraulic piston assembly, preventing any leakage of water or other fluids.

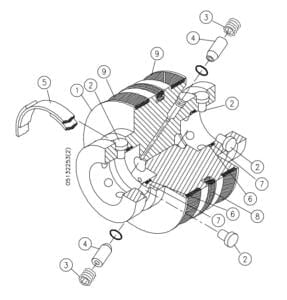

Artículo | Número de pieza | Descripción | Cantidad |

1 | 72101205 | Pistón de ariete, 5.50 | 1 |

2 | 05074380 | Pasador de horquilla | 12 |

3 | 05049887 | Tornillo de fijación | 2 |

4 | 10148757 | Conjunto de válvula de retención | 2 |

5 | 05088364 | Anillo de retención | 2 |

6 | 05049994 | Anillo de respaldo, 1,50 x 1,75 | 2 |

7 | 05087713 | Junta tórica, 1.25 x 1.50 x .13 | 2 |

8 | 05120118 | Montaje del sello | 1 |

9 | 05120100 | Cojinete | 2 |

| 72168337 | Kit de piezas de repuesto | ||

| Incluye los artículos 4, 5, 6, 7, 8 y 9 |

The Seal Assembly 05120118 typically includes several components, such as a piston seal, rod seal, backup rings, and O-rings.

These components work together to create a secure, tight seal that can withstand the high pressures and temperatures associated with waterjet cutting applications.

The piston seal and rod seal are two of the most critical components of the Seal Assembly in hydraulic piston assembly.

The piston seal is used to seal the gap between the piston and the cylinder wall, while the rod seal is used to seal the gap between the piston rod and the cylinder head.

These seals are typically made of a high-performance material, such as polyurethane or PTFE, to withstand the high pressures and temperatures associated with waterjet cutting applications.

The backup rings in the Seal Assembly are designed to provide support to the main sealing elements and prevent extrusion or damage under high pressure.

The O-rings are used to provide additional sealing and prevent any leakage between the components of hydraulic piston assembly.

The Seal Assembly 05120118 of hydraulic piston assembly is designed to be a replacement part for the 90k waterjet pump.

It is important to choose a Seal Assembly that is compatible with the specific model of the waterjet pump and that meets the necessary requirements for pressure, temperature, and chemical exposure.

What are the common causes of Seal Assembly failure?

1. Contamination

Contamination can come from a variety of sources, including dirt, dust, debris, or other foreign materials that can get into the Seal Assembly.

Contamination can cause abrasion or wear on the sealing surfaces, leading to leakage or reduced performance.

To prevent contamination, it is important to keep the components of hydraulic piston assembly clean and to use appropriate filtration systems.

2. High Temperature

High temperatures can cause the Seal Assembly to degrade or become brittle, leading to leakage or failure.

The Seal Assembly should be selected based on the specific temperature requirements of the application.

3. High Pressure

High pressure can cause the Seal Assembly to extrude or deform, leading to leakage or failure.

The Seal Assembly should be selected based on the specific pressure requirements of the application.

4. Chemical Exposure

Exposure to chemicals can cause the Seal Assembly to degrade or become damaged, leading to leakage or failure.

The Seal Assembly of hydraulic piston assembly should be selected based on the specific chemical requirements of the application.

5. Improper Installation

Improper installation of the Seal Assembly, such as over-compression or under-compression, can cause damage to the sealing surfaces or other components, leading to leakage or failure.

6. Wear and Tear

Over time, the Seal Assembly of hydraulic piston assembly can become worn or damaged, leading to leakage or failure.

This can be caused by factors such as friction, vibration, or exposure to harsh operating conditions.

7. Incompatible Seal Assembly

Using a Seal Assembly that is not compatible with the specific model of the waterjet pump or that does not meet the necessary requirements for pressure, temperature, or chemical exposure can cause equipment failure or reduced performance.

What are some common issues that can arise during Seal Assembly installation in hydraulic piston assembly?

1. Damage to the Seal Assembly

The Seal Assembly is a delicate component of hydraulic piston assembly that can be easily damaged during installation if it is not handled carefully.

It is important to handle the Seal Assembly with care and to use the recommended installation tools and techniques.

Damage to the Seal Assembly can lead to leakage or failure.

2. Incorrect Installation Depth

The Seal Assembly should be installed to the correct depth to ensure proper sealing.

If the Seal Assembly is installed too deep or not deep enough, it can cause issues with sealing and lead to leakage or failure.

The correct installation depth can be determined by measuring the depth of the old Seal Assembly, if applicable, or by following the manufacturer’s guidelines.

3. Over-Compression or Under-Compression

The Seal Assembly should be compressed to the correct level to ensure proper sealing.

Over-compression or under-compression can cause damage to the Seal Assembly or other components and lead to leakage or failure.

The correct compression level can be determined by measuring the compression level of the old Seal Assembly, if applicable, or by following the manufacturer’s guidelines.

4. Leaks

Leaks can occur during installation if the Seal Assembly is not installed properly or if there are other issues with the waterjet pumpLeaks can be caused by a variety of factors, including damage to the Seal Assembly, incorrect installation depth, or other issues.

5. Improper Alignment

The Seal Assembly should be aligned properly during installation to ensure proper sealing.

If the Seal Assembly is not aligned properly, it can cause damage to the Seal Assembly or other components and lead to leakage or failure.

The Seal Assembly should be aligned with the shaft and housing to ensure proper functioning.

6. Incompatible Seal Assembly

Using an incompatible Seal Assembly can cause issues during installation and lead to equipment failure or reduced performance.

It is important to use a Seal Assembly that is compatible with the specific model of the waterjet pump and the operating conditions of the application.

7. Improper Lubrication

The Seal Assembly should be lubricated with a compatible lubricant before installation to ensure that it can be installed smoothly and without damage.

If the Seal Assembly is not lubricated properly, it can cause damage to the Seal Assembly or other components and lead to leakage or failure.

8. Improper Torque

The Seal Assembly should be tightened to the correct torque to ensure proper sealing.

If the Seal Assembly is not tightened to the correct torque, it can cause damage to the Seal Assembly or other components and lead to leakage or failure.

Cualquier otro requisito para el conjunto de pistón hidráulico o Bomba de chorro de agua de 90.000 psiPor favor contáctenos.