Descripción

The Retaining Ring 05088364 is a component of hydraulic piston assembly used in the Bomba de chorro de agua de 90.000 psi.

It is a snap ring that is used to retain the check valve assembly in place within the hydraulic piston assembly system of the waterjet pump.

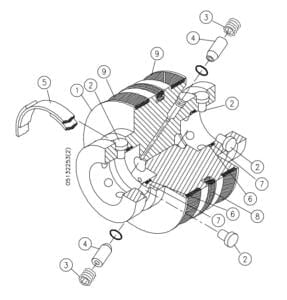

Artículo | Número de pieza | Descripción | Cantidad |

1 | 72101205 | Pistón de ariete, 5.50 | 1 |

2 | 05074380 | Pasador de horquilla | 12 |

3 | 05049887 | Tornillo de fijación | 2 |

4 | 10148757 | Conjunto de válvula de retención | 2 |

5 | 05088364 | Anillo de retención | 2 |

6 | 05049994 | Anillo de respaldo, 1,50 x 1,75 | 2 |

7 | 05087713 | Junta tórica, 1.25 x 1.50 x .13 | 2 |

8 | 05120118 | Montaje del sello | 1 |

9 | 05120100 | Cojinete | 2 |

| 72168337 | Kit de piezas de repuesto | ||

| Incluye los artículos 4, 5, 6, 7, 8 y 9 |

The Retaining Ring 05088364 is designed to fit the specific dimensions of the check valve assembly and the hydraulic system of the 90k waterjet pump.

The Retaining Ring 05088364 is typically made of stainless steel or other high-strength materials that can withstand the high pressures and stresses of the waterjet pump.

Q: How can I install the Retaining Ring onto check valve assembly of hydraulic piston assembly?

Un: To install a retaining ring onto a check valve assembly of hydraulic piston assembly, you will need a retaining ring pliers or other suitable tool.

- Ensure that the check valve assembly is clean and free of debris or corrosion.

- Check the retaining ring for any signs of wear or damage. If the retaining ring is worn or damaged, it should be replaced.

- Locate the groove on the check valve assembly where the retaining ring will be installed.

- Insert one end of the retaining ring into the groove on the check valve assembly.

- Use the retaining ring pliers or other suitable tool to compress the retaining ring and guide it into the groove.

- Continue to compress and guide the retaining ring around the groove until it is fully installed.

- Once the retaining ring is in place, inspect it to ensure that it is properly seated and secure in the groove.

- Perform a pressure test on the waterjet pump to ensure that the retaining ring is properly seated and the check valve assembly is functioning properly.

Q: What are some common signs of wear or damage to look for in the Retaining Ring of hydraulic piston assembly?

Un:

1. Cracks

Check the retaining ring for any visible cracks or fractures.

These can be an indication that the retaining ring has been subjected to excessive stress and may be at risk of failure.

2. Deformation

Look for any signs of deformation or warping in the retaining ring.

Deformation can occur if the retaining ring has been exposed to excessive heat or pressure, or if it has been struck by an object.

3. Wear marks

Inspect the retaining ring for any visible wear marks or grooves, such as nicks or burrs.

These can be an indication that the retaining ring is not properly seated or that it is experiencing excessive stress.

4. Corrosion

Check the retaining ring for any signs of corrosion, such as discoloration or pitting.

Corrosion can weaken the retaining ring and make it more prone to failure.

5. Improper fit

Check that the retaining ring fits properly in the designated groove and seats flush against the check valve assembly.

If the ring is not properly seated or does not fit properly, it may need to be replaced.

6. Loose or rattling

If the retaining ring is loose or rattling, this can be an indication that it is not properly seated or that it has become worn or damaged.

A loose retaining ring can cause vibration or movement in the waterjet pump, which can cause damage or failure.

7. Reduced performance

If the retaining ring is not functioning properly, this can affect the performance of the waterjet pump.

For example, the pump may not maintain pressure or may experience reduced flow rates.

If you notice any changes in the performance of the waterjet pump, it is important to inspect the retaining ring to determine if it is the cause of the issue.

8. Leakage

If you notice any leakage or seepage around the retaining ring, this can be an indication that it is not properly seated or that it has become worn or damaged.

Leakage can cause a drop in pressure or flow rates, and may alsopose safety risks to personnel.

9. Excessive noise

If you hear excessive noise coming from the waterjet pump, this can be an indication that the retaining ring is not properly seated or that it has become worn or damaged.

Excessive noise can be caused by vibration or movement in the pump, which can be a sign of a loose or damaged retaining ring.

What cleaning solution is recommend for the Retaining Ring of hydraulic piston assembly?

The specific cleaning solution recommended for the Retaining Ring 05088364 may vary depending on the specific type of contamination present.

Here are some general guidelines that can help to ensure safe and effective cleaning of the retaining ring of hydraulic piston assembly:

1. Use a mild cleaning solution

It is important to use a cleaning solution that is appropriate for the material of the retaining ring and that is mild enough to avoid causing damage or corrosion.

A mild soap and water solution or a specialized cleaning solution recommended by the manufacturer may be suitable.

2. Avoid harsh chemicals

Avoid using harsh chemicals or solvents that may damage or corrode the retaining ring or other components of the waterjet pump. This can include acids, alkalis, or other strong chemicals.

3. Use a soft brush or cloth

Use a soft brush or cloth to gently remove dirt and debris from the retaining ring of hydraulic piston assembly.

Avoid using abrasive materials or tools that may scratch or damage the surface of the ring.

4. Rinse thoroughly

After cleaning the retaining ring of hydraulic piston assembly, rinse it thoroughly with clean water to remove any remaining residue or cleaning solution.

5. Dry the ring

Once the retaining ring has been cleaned and rinsed, use a soft cloth or air blower to dry it thoroughly before reinstalling it in the waterjet pump.

Cualquier otro requisito para el conjunto de pistón hidráulico o Bomba de chorro de agua de 90.000 psiPor favor contáctenos.