Descripción

The Clevis Pin 05074380 is a component of hydraulic piston assembly used in the Bomba de chorro de agua de 90.000 psi.

The Clevis Pin is a small, cylindrical metal pin with a flat head and a hole through the center.

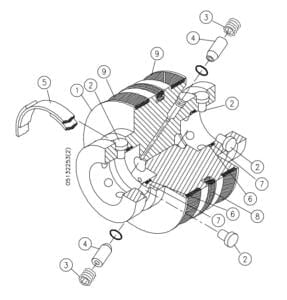

Artículo | Número de pieza | Descripción | Cantidad |

1 | 72101205 | Pistón de ariete, 5.50 | 1 |

2 | 05074380 | Pasador de horquilla | 12 |

3 | 05049887 | Tornillo de fijación | 2 |

4 | 10148757 | Conjunto de válvula de retención | 2 |

5 | 05088364 | Anillo de retención | 2 |

6 | 05049994 | Anillo de respaldo, 1,50 x 1,75 | 2 |

7 | 05087713 | Junta tórica, 1.25 x 1.50 x .13 | 2 |

8 | 05120118 | Montaje del sello | 1 |

9 | 05120100 | Cojinete | 2 |

| 72168337 | Kit de piezas de repuesto | ||

| Incluye los artículos 4, 5, 6, 7, 8 y 9 |

1. Size and dimensions

The Clevis Pin 05074380 has specific size and dimensional requirements that must be met for proper fit and function in the waterjet pump.

When replacing the Clevis Pin, it is important to use the correct size and type of pin to ensure safe and effective operation of the pump.

2. Material and construction

The Clevis Pin 05074380 is made of high-quality, durable materials such as steel or stainless steel that are designed to withstand the high pressures and stresses involved in the operation of the waterjet pump.

The pin is typically heat-treated to increase its strength and durability.

3. Function and placement

The Clevis Pin is a small but critical component of hydraulic piston assembly that plays a role in securing various components in the pump, such as the plunger and the connecting rod.

The pin is typically placed through a hole in the component being secured and through a corresponding hole in the pump frame or other component.

4. Proper installation

Proper installation of the Clevis Pin and other components in the waterjet pump is critical for safe and effective operation.

When installing the Clevis Pin, it is important to ensure that it is properly aligned and seated in the component being secured and that it is tightened to the manufacturer’s specifications.

What are some signs that the Clevis Pin of hydraulic piston assembly needs to be replaced?

1. Unusual noises

If you hear unusual noises coming from your waterjet pump, such as rattling or banging, it could be a sign that the Clevis Pin is worn or damaged.

This may be due to the pin becoming loose or shifting within the component it is securing.

2. Rendimiento reducido

If you notice a decrease in the performance of your waterjet pump, such as a decrease in output pressure or flow rate, it could be a sign that the Clevis Pin is worn or damaged.

This may be due to the pin becoming loose or shifting within the component it is securing, or due to other issues with the pump.

3. Vibration

If you feel excessive vibration or shaking in your waterjet pump, it could be a sign that the Clevis Pin of hydraulic piston assembly is worn or damaged.

This may be due to the pin becoming loose or shifting within the component it is securing, or due to other issues with the pump.

4. Leakage

If you notice fluid leaking from your waterjet pump, it could be a sign that the Clevis Pin is worn or damaged.

This may be due to the pin becoming loose or shifting within the component it is securing, or due to other issues with the pump.

5. Visual damage

If you inspect the Clevis Pin and notice visible signs of wear ordamage, such as bending, cracking, or corrosion, it is a clear sign that the pin needs to be replaced.

These signs of damage can indicate that the Clevis Pin of hydraulic piston assembly is no longer able to securely hold the component in place.

This can lead to further damage or failure of the waterjet pump.

6. Corrosion or rust

If you notice corrosion or rust on the Clevis Pin of hydraulic piston assembly, it is a clear sign that the pin needs to be replaced.

Corrosion or rust can weaken the pin and cause it to fail, leading to further damage or failure of the waterjet pump.

7. Reduced lifespan of the pin

The expected lifespan of the Clevis Pin in a waterjet pump can vary depending on several factors, such as the frequency of use, the operating conditions, and the quality of maintenance and care.

If you notice that the Clevis Pin is wearing out or requiring replacement more frequently than expected, it could be a sign that there are issues with the pump or other components that are causing excessive stress or wear on the pin.

Q: How often should I lubricate the Clevis Pin of hydraulic piston assembly?

Un: The frequency of lubrication for the Clevis Pin of hydraulic piston assembly in your waterjet pump can vary depending on several factors, such as:

the frequency of use, the operating conditions, and the quality of maintenance and care.

As a general guideline, it is recommended to lubricate the Clevis Pin at least once every 50 hours of operation or as recommended by the manufacturer.

Lubricating the Clevis Pin helps to reduce friction and wear between the pin and the component it is securing.

It can help to prolong the lifespan of the pin and prevent premature wear or damage.

It is important to use a high-quality lubricant that is compatible with the waterjet pump and that meets the manufacturer’s specifications.

When lubricating the Clevis Pin, it is important to follow the manufacturer’s guidelines for lubrication and to use the recommended amount of lubricant.

Over-lubrication can lead to excess buildup of lubricant, which can attract dirt and debris and potentially lead to damage or failure of the pin or other components of hydraulic piston assembly.

Any other requirements for hydraulic piston assembly or 90,000 psi waterjet pump, please contáctenos.