Descripción

The Backup Ring 05049994 is a specific type of static sealing component of hydraulic piston assembly used in the Bomba de chorro de agua de 90.000 psi.

The Backup Ring 05049994 has a specific size of 1.50 x 1.75 inches, which refers to its inside diameter and outside diameter respectively.

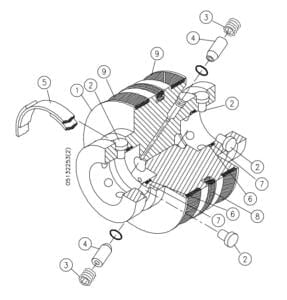

Artículo | Número de pieza | Descripción | Cantidad |

1 | 72101205 | Pistón de ariete, 5.50 | 1 |

2 | 05074380 | Pasador de horquilla | 12 |

3 | 05049887 | Tornillo de fijación | 2 |

4 | 10148757 | Conjunto de válvula de retención | 2 |

5 | 05088364 | Anillo de retención | 2 |

6 | 05049994 | Anillo de respaldo, 1,50 x 1,75 | 2 |

7 | 05087713 | Junta tórica, 1.25 x 1.50 x .13 | 2 |

8 | 05120118 | Montaje del sello | 1 |

9 | 05120100 | Cojinete | 2 |

| 72168337 | Kit de piezas de repuesto | ||

| Incluye los artículos 4, 5, 6, 7, 8 y 9 |

Backup rings are typically made from high-strength materials harder than the main sealing element, such as PTFE (polytetrafluoroethylene) or other suitable materials.

They can withstand the high pressures and abrasive conditions of hydraulic systems and waterjet cutting.

During operation, the backup ring is installed in a groove behind the O-ring or other sealing component, providing support and preventing extrusion under high pressure.

The backup ring is typically used in conjunction with other sealing components, such as O-rings or hydraulic seals, to provide a reliable and effective seal in hydraulic piston assembly.

The backup rings can help to extend the service life of O-rings and other sealing components by providing additional support and limiting the amount of pressure that can act on the seal.

This can help to prevent extrusion and premature failure of the seal, reducing the need for maintenance and replacement of the sealing components.

What are some common signs of wear and tear in Backup Rings of hydraulic piston assembly?

1. Cracking

Cracking is a common sign of wear and tear in Backup Rings of hydraulic piston assembly.

Cracks can occur due to exposure to high pressures, temperatures or chemical exposure.

Cracks can also occur due to improper installation or mishandling.

2. Deformation

Deformation is another common sign of wear and tear in Backup Rings of hydraulic piston assembly.

Deformation can occur due to excessive compression forces, improper installation or exposure to high pressures.

3. Tearing

Tearing is a sign of wear and tear in Backup Rings of hydraulic piston assembly.

Tearing can occur due to exposure to abrasive particles or improper installation.

4. Extrusion

Extrusion is a sign of wear and tear in Backup Rings of hydraulic piston assembly.

Extrusion can occur when the Backup Ring is no longer able to provide support to the main sealing element, allowing it to be forced out of the sealing groove.

5. Discoloration

Discoloration is a sign of wear and tear in Backup Rings of hydraulic piston assembly.

Discoloration can occur due to exposure to chemicals or high temperatures.

6. Reduced Performance

Reduced performance is a sign of wear and tear in Backup Rings of hydraulic piston assembly.

Reduced performance can include decreased sealing effectiveness, increased leakage or decreased equipment efficiency.

7. Increased Wear on Seal

Increased wear on themain sealing element is another sign of wear and tear in Backup Rings of hydraulic piston assembly.

When the Backup Ring is no longer able to provide adequate support, the main sealing element can experience increased wear and tear from exposure to high pressures or abrasive particles.

8. Leakage

Leakage is a sign of wear and tear in Backup Rings of hydraulic piston assembly.

Leakage can occur when the Backup Ring is no longer able to provide reliable sealing, allowing fluid to escape from the sealing area.

What are some common causes of Backup Ring failure?

Backup Rings are designed to provide support to the main sealing element and prevent extrusion, which is the deformation or displacement of the seal material under pressure.

However, Backup Rings can be subject to damage or failure under certain circumstances.

Here are some common causes of Backup Ring damage:

1. Improper Installation

Improper installation of the Backup Ring in hydraulic piston assembly can cause damage to the ring or the main sealing element.

The Backup Ring must be installed properly and in the correct orientation to ensure proper support to the seal.

2. Chemical Exposure

Backup Rings can be damaged by exposure to chemicals or fluids that are not compatible with the Backup Ring material.

It is important to choose Backup Rings that are compatible with the chemicals and fluids used in the waterjet cutting process.

3. High Pressure

Backup Rings can be damaged by high pressure or pressure spikes in the waterjet cutting equipment.

Backup Rings must be able to withstand the maximum operating pressure of the equipment to prevent extrusion and other types of damage.

4. Temperature Extremes

Backup Rings can be damaged by exposure to extreme temperatures.

In waterjet cutting, the Backup Ring must be able to withstand the high temperatures generated by the cutting process.

5. Compression Damage

Backup Rings can be damaged by excessive compression forces during installation or operation.

This can cause the Backup Ring to deform or lose its shape, which can lead to extrusion or other types of damage.

6. Wear and Tear

Over time, Backup Rings can experience wear and tear from repeated use and exposure to harsh conditions in the waterjet cutting process.

This can include cracking, tearing, or other types of damage that can compromise the performance of the Backup Ring.

7. Inadequate Support

Backup Rings must be able to provide adequate support to the main sealing element to prevent extrusion and other types of damage.

If the Backup Ring is too small or too weak for the application, it may not be able to provide sufficient support, leading to damage or failure.

8. Vibration and Shock

Vibration and shock can cause Backup Rings to shift or become dislodged, leading to damage or failure.

It is important to secure the Backup Ring properly to prevent movement during operation.

9. Inadequate Lubrication

Inadequate lubrication can cause Backup Rings to wear down or become damaged over time.

It is important to use the proper lubrication for the specific waterjet cutting application and to follow the manufacturer’s guidelines for lubrication.

Cualquier otro requisito para el conjunto de pistón hidráulico o Bomba de chorro de agua de 90.000 psiPor favor contáctenos.