Descripción

Piezas de repuesto de ABB Robotics

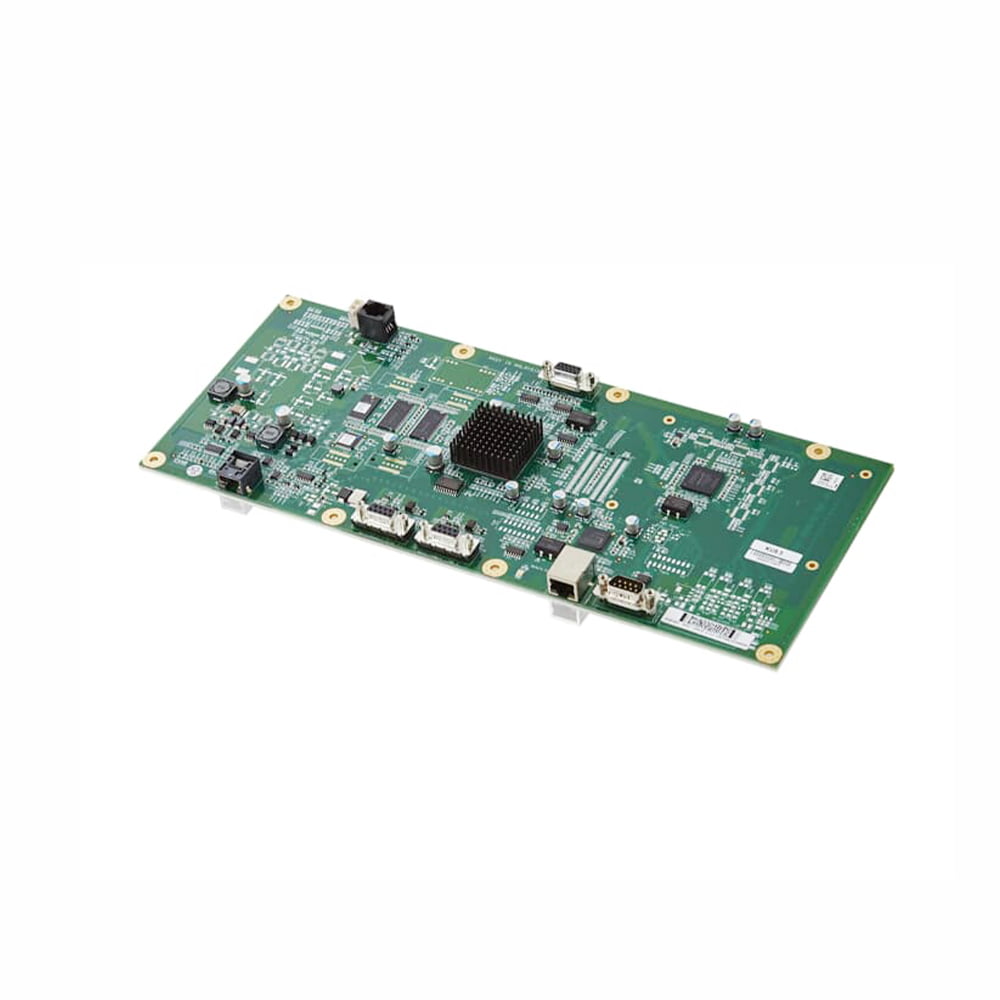

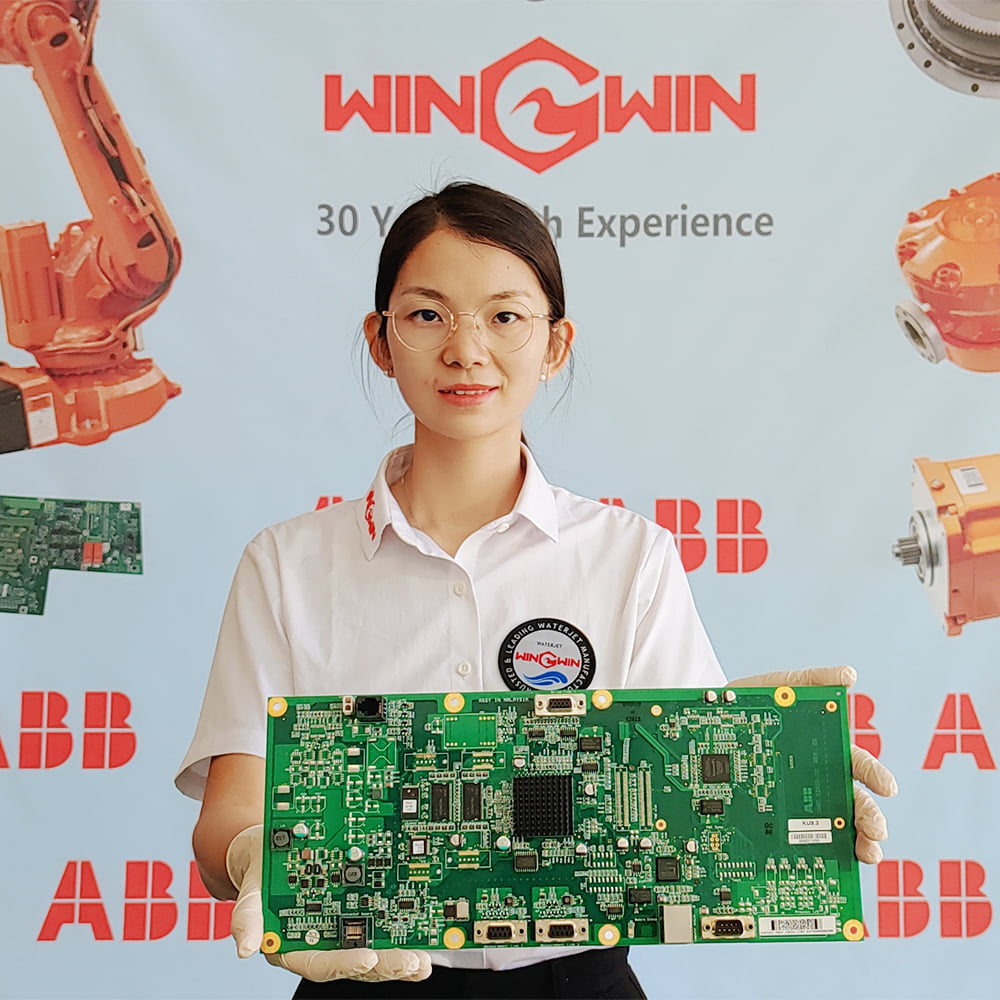

Item number: 3HAC12815-1

Item name: DSQC 601 Axis Computer

Detalles: utilizado en los brazos robóticos de ABB

Win-Win proporciona soluciones de chorro de agua para robots, repuestos para robótica ABB, etc.

Related robot waterjet cutting workstation & Piezas de repuesto para robótica ABB:

Sistema robótico de corte por chorro de agua & Piezas de celdas de chorro de agua para robots: Estación de trabajo robótica de chorro de agua Yaskawa y piezas relacionadas, Estación de trabajo robótica de chorro de agua Fanuc y piezas relacionadas, Estación de trabajo robótica de chorro de agua ABB y Piezas de repuesto para robótica ABB.

FAQ of platform waterjet machine & robot waterjet system & ABB robotics spare parts:

A. What are the cutting speeds of the robotic water jet cutting machines for different materials?

The cutting speed of a robotic water jet cutting machine depends mainly on the following factors:

Type and hardness of the material: Hard materials such as steel, stone or ceramics usually require slower cutting speeds, while softer materials such as car interiors, rubber, foam or food can be cut faster.

Thickness of the material: the thicker the material, the slower the required cutting speed is usually.

Abrasive used: For abrasive water jet cutting, the type and availability of abrasive will affect the cutting speed.

Cutting pressure: Higher working pressures increase cutting speeds, but also increase wear and tear on the equipment.

Required cut quality: In order to achieve a higher cut quality, some cutting speed may need to be sacrificed.

To give you a general idea, here are some approximate cutting speed ranges for different materials (just a reference, actual speeds may vary due to the factors mentioned above and specific equipment):

Soft materials (e.g. car interiors, rubber, foam): up to tens to hundreds of mm/sec.

Aluminum (medium thickness): possible in the range of 5 to 50 mm/sec.

Stainless steel (medium thickness): possibly in the range of 2-20 mm/sec.

Stone or ceramic: possible in the range of 1-15 mm/sec.

Please note that the above speeds are a rough estimate and are not absolute. In order to obtain the optimum cutting speed for a particular material and thickness, it is recommended to carry out some tests or consult the machine supplier.

B. What kind of software is used for water jet robotic cutting? Can it be integrated with other CAD/CAM systems?

Water jet robotic cutting systems are usually equipped with software specifically designed for water jet cutting to ensure accurate and efficient cutting. These software not only support the design of cutting paths, but also provide advanced features such as collision detection, cutting parameter optimization and robot motion simulation.

Common water jet cutting software includes:

Wine-Win’s own designed software: programmed according to the customer’s cutting conditions and needs, allowing cutting efficiency to be optimized.

OMAX Intelli-MAX Software Suite: is a suite of software developed by OMAX for its water jet cutting machines.

FlowPath/FlowCut: Specialized software provided by Flow Waterjet to design and drive their waterjet cutting systems.

IGEMS Waterjet Module: A stand-alone waterjet CAM system that can also be integrated with other modules to provide a wider range of functionality.

Most of these software programs support common CAD file formats such as DXF, DWG, IGES and STEP, which means that users can easily import design drawings from mainstream CAD software (e.g. AutoCAD, SolidWorks, CATIA, NX, etc.).

In addition, to further streamline and automate production processes, some water jet cutting software can be integrated with a wider range of CAD/CAM systems. For example, through APIs, plug-ins, or specific import/export functions, it is possible to integrate a waterjet CAM system with a PLM/PDM system, ERP system, or other manufacturing execution system (MES).

When selecting software and integration solutions, it is recommended to discuss your specific needs in detail with the machine and software vendors to ensure that you get the solution that best fits your production process.

Somos el proveedor de máquinas de corte por chorro de agua, estaciones de trabajo robóticas por chorro de agua y también piezas de repuesto robóticas ABB relacionadas, etc. Si está buscando estos productos, bienvenido a dejarnos un mensaje, nos pondremos en contacto con usted lo antes posible.

Para obtener más información sobre los productos de chorro de agua Win-Win, acceda a los siguientes enlaces:

https://www.youtube.com/channel/UC-D9PKZlhw2fZhMnnzefcgQ/