Descripción

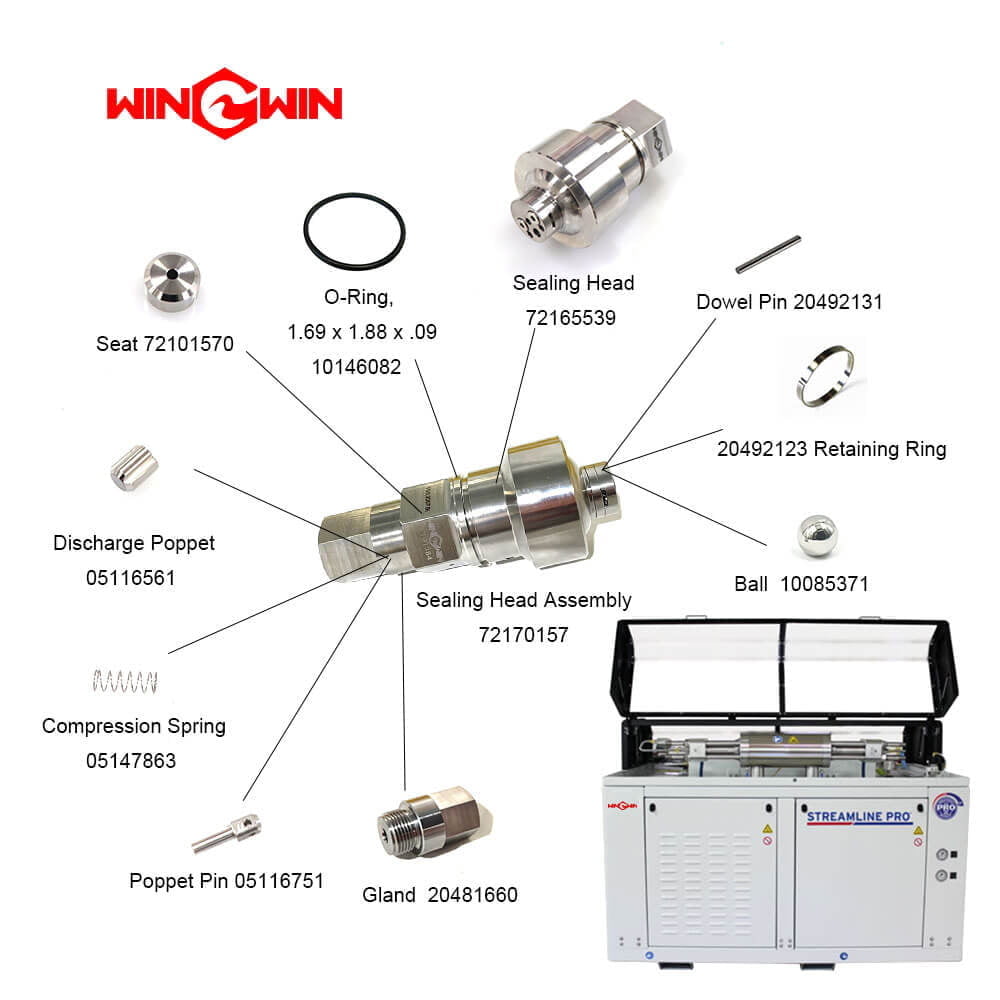

90K PSI Pump Parts: Gland 20481660

In 90k psi pump parts of a waterjet intensifier pump, the gland is a component that helps to maintain the high pressure required for the pump to function properly.

The gland is designed to prevent the water from leaking out of the pump, which can cause a loss of pressure and reduced performance.

Artículo | Número de pieza | Descripción | Cantidad | Artículo | Número de pieza | Descripción | Cantidad |

1 | 05146592 | Junta, soporte de Topworks | 2 | 14 | 72162253 | Desatascador | 2 |

2 | 20476377 | Soporte, Topworks | 2 | 15 | 05130091 | Cartucho de sello hidráulico | 2 |

3 | 10118206 | Junta tórica, 1.31×1.56× .13 | 2 | 16 | 72175989 | Brida de retención de buje | 2 |

4 | 05144514 | Cilindro hidráulico | 1 | 17 | 72158494 | Conjunto de sello UHP | 2 |

5 | 05098991 | Tornillo de cabeza de zócalo, 3/8-16×3-3/4 | 8 | 18 | 72166738 | Cilindro UHP | 2 |

6 | 95688743 | Arandela de cerradura, .38 | 8 | 19 | 72163802 | Liner | 2 |

7 | 72101190 | Conjunto de pistón | 1 | 20 | 20474325 | Stud, 1-1/8-12×18.31 | 8 |

8 | 10074771 | Junta tórica, 5.25×5.50× .13 | 2 | 21 | 72170157 | Conjunto de cabezal de sellado | 2 |

9 | 05120092 | Anillo de respaldo, 5.25×5.50× .13 | 2 | 22 | 72178493 | Montaje de brida | 2 |

10 | 72175997 | Culata hidráulica | 2 | 23 | 20464590 | Lavadora plana, 1.13 | 8 |

11 | 05097886 | Tornillo de cabeza de zócalo, 3/4-16×2-1/4 | 12 | 24 | 20461761 | Tuerca hexagonal, 1-1/8-12 | 8 |

12 | 05144183 | Conjunto del espaciador, interruptor de proximidad | 2 | 25 | 20489339 | Adaptador, JIC/tubería, 50× .38 | 1 |

05144191 | Junta tórica, .69× .88× .09 | 26 | 72176756 | Junta tórica, 3.88×4.25× .19 | 6 | ||

13 | 72141569 | Kit, interruptor de proximidad | 2 | ||||

| 72134224 | Interruptor de proximidad | ||||||

95119012 | Tornillo de cabeza de zócalo, 1/4-20×1 |

The gland of 90k psi pump parts is typically located on the top of the intensifier block, where it fits tightly around the high-pressure plunger.

It is usually held in place by a gland nut or clamp that applies pressure to the gland to create a tight seal.

It is made of a hard material such as ceramic or carbide, which is able to withstand the high pressure and abrasion of the waterjet stream.

Over time, the gland may wear down or become damaged, which can lead to leaks and reduced pump performance.

Replacing the gland is typically a straightforward process, but it should only be done by a trained professional.

Ensure that the new gland is installed correctly and the gland nut or clamp is tightened to the correct torque specifications, so that the pump is properly sealed.

Use the correct replacement gland of 90k psi pump parts that is designed for the specific model of the pump you are working with.

If the gland is not properly maintained or replaced when necessary, it can lead to more serious damage to the pump or even complete failure, which can be costly to repair.

Therefore, it is important to follow our recommended maintenance schedule and procedures for the 90k psi pump parts of the pump.

How can you tell if the gland of 90k psi pump parts in a waterjet intensifier pump is damaged or worn down?

1. Fugas

One of the most obvious signs that the gland of 90k psi pump parts needs to be replaced is if there are visible leaks around the gland area.

Leaks can occur due to wear and tear on the gland or if the gland is not properly tightened.

2. Reduced pressure

If you notice a decrease in the pressure or flow rate of the waterjet, it could be a sign that the gland is not creating a tight seal, which can result in a loss of pressure.

3. Unusual noises

If you hear unusual noises coming from the pump, such as whining or grinding sounds, it could be a sign that the gland is damaged or worn and needs to be replaced.

4. Increased temperature

If the temperature of the water or the pump itself is higher than usual, it could be a sign that the gland is not functioning properly and needs to be replaced.

5. Desgaste visual

If you inspect the gland and notice visible wear or damage, such as cracks or chips, it is likely time to replace the gland.

If you notice any of these signs, it is important to address the issue as soon as possible.

Prevent further damage to the pump and ensure that it is operating safely and efficiently.

It is recommended to have a trained professional inspect and replace the gland to ensure that it is done correctly and safely.

In addition to the signs mentioned above, here are some more details on what to pay attention to:

1. Gland nut or clamp

If the gland nut or clamp is loose or damaged, it can cause leaks and reduce the efficiency of the pump.

Make sure that the gland nut or clamp is tightened to our recommended torque specifications and it is not damaged.

2. Water quality

The quality of the water being used in the pump can also affect the lifespan of the gland.

If the water is dirty or contains abrasive particles, it can cause the gland of 90k psi pump parts to wear down more quickly.

Make sure to use clean, high-quality water and perform routine maintenance and cleaning of the pump.

3. Age of the pump

As the pump ages, it may be more prone to wear and tear, which can cause the gland of 90k psi pump parts to deteriorate more quickly.

If your pump is several years old and has not had the gland replaced recently, it may be time to consider replacing it.

Replacing the gland of 90k psi pump parts in a waterjet intensifier pump can be a hazardous task.

Because the pump operates with high pressure water that can cause serious injuries.

It is important to take the following safety precautions when replacing the gland of 90k psi pump parts:

1. Wear personal protective equipment (PPE)

Before starting any work on the pump,

make sure to wear appropriate PPE, including safety glasses, gloves, and protective clothing.

2. Shut off power

Before starting to work on the pump,

make sure to shut off the power to the pump and lockout/tagout the power source to prevent accidental start-up.

3. Relieve pressure

Before removing the gland of 90k psi pump parts,

make sure to relieve the pressure from the pump by opening the pressure relief valve or disconnecting the water supply.

4. Use lifting equipment

The intensifier block and other 90k psi pump parts of the pump can be heavy and difficult to remove.

Use lifting equipment or ask for help to safely remove and replace these components.

5. Use correct tools

Use the correct tools when removing and installing the gland.

Avoid damaging the gland or other 90k psi pump parts of the pump.

6. Follow manufacturer’s instructions

Always follow our instructions when replacing the gland and use only the recommended replacement parts.

7. Tighten gland nut or clamp

Make sure to properly tighten the gland nut or clamp to our recommended torque specifications.

8. Dispose of old part

Dispose of the old gland safely and properly.

9. Observe safe work practices

Use appropriate tools and techniques when working on the pump to avoid injuries or damage to the pump.

10. Test pump after replacement

After replacing the gland of 90k psi pump parts, test the pump to ensure that it is operating correctly and safely.

Check for any leaks or unusual noises.

Make sure that the pressure and flow rate are within our recommended range.

If you have any other requirements of 90k psi pump parts, please contáctenos.