Descripción

90K psi Parts: Poppet Pin 05116751

Artículo | Número de pieza | Descripción | Cantidad | Artículo | Número de pieza | Descripción | Cantidad |

1 | 05146592 | Junta, soporte de Topworks | 2 | 14 | 72162253 | Desatascador | 2 |

2 | 20476377 | Soporte, Topworks | 2 | 15 | 05130091 | Cartucho de sello hidráulico | 2 |

3 | 10118206 | Junta tórica, 1.31×1.56× .13 | 2 | 16 | 72175989 | Brida de retención de buje | 2 |

4 | 05144514 | Cilindro hidráulico | 1 | 17 | 72158494 | Conjunto de sello UHP | 2 |

5 | 05098991 | Tornillo de cabeza de zócalo, 3/8-16×3-3/4 | 8 | 18 | 72166738 | Cilindro UHP | 2 |

6 | 95688743 | Arandela de cerradura, .38 | 8 | 19 | 72163802 | Liner | 2 |

7 | 72101190 | Conjunto de pistón | 1 | 20 | 20474325 | Stud, 1-1/8-12×18.31 | 8 |

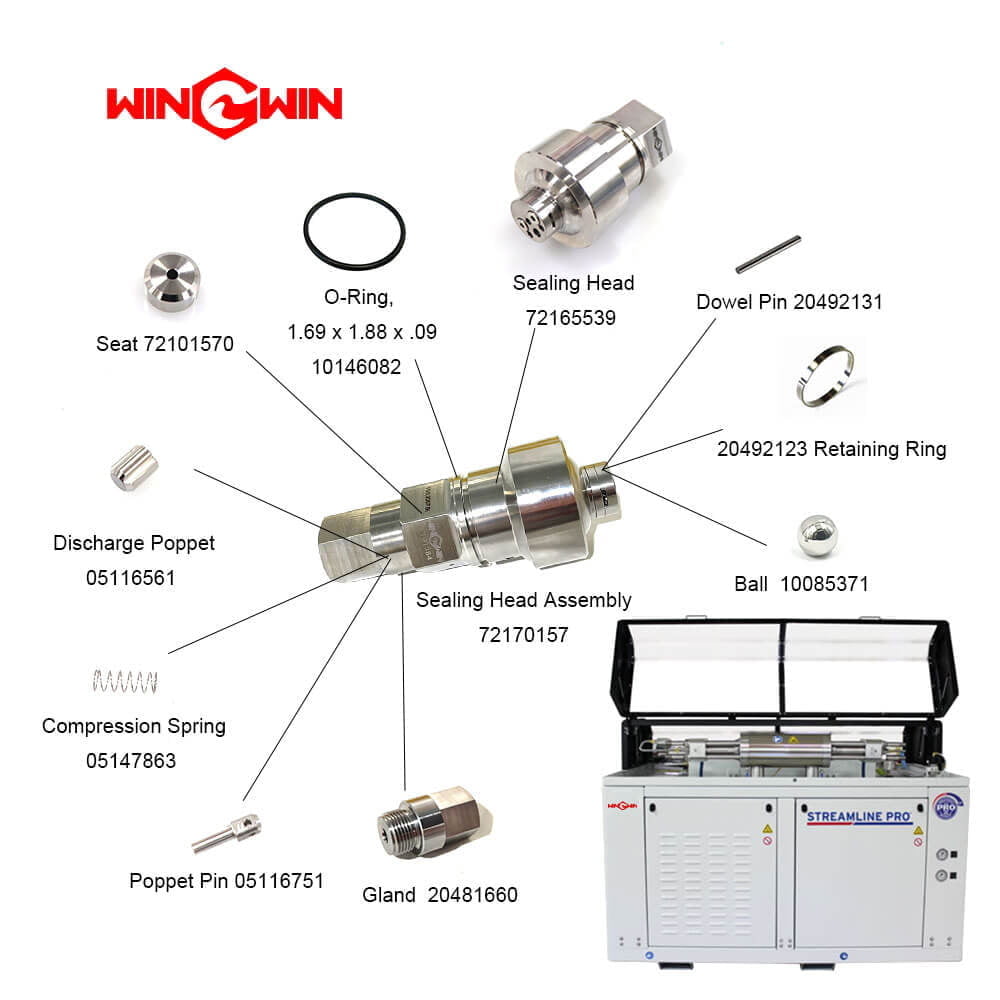

8 | 10074771 | Junta tórica, 5.25×5.50× .13 | 2 | 21 | 72170157 | Conjunto de cabezal de sellado | 2 |

9 | 05120092 | Anillo de respaldo, 5.25×5.50× .13 | 2 | 22 | 72178493 | Montaje de brida | 2 |

10 | 72175997 | Culata hidráulica | 2 | 23 | 20464590 | Lavadora plana, 1.13 | 8 |

11 | 05097886 | Tornillo de cabeza de zócalo, 3/4-16×2-1/4 | 12 | 24 | 20461761 | Tuerca hexagonal, 1-1/8-12 | 8 |

12 | 05144183 | Conjunto del espaciador, interruptor de proximidad | 2 | 25 | 20489339 | Adaptador, JIC/tubería, 50× .38 | 1 |

05144191 | Junta tórica, .69× .88× .09 | 26 | 72176756 | Junta tórica, 3.88×4.25× .19 | 6 | ||

13 | 72141569 | Kit, interruptor de proximidad | 2 | ||||

| 72134224 | Interruptor de proximidad | ||||||

95119012 | Tornillo de cabeza de zócalo, 1/4-20×1 |

A poppet pin, one of 90k psi parts, is a crucial component in the high-pressure hydraulic system of a waterjet intensifier pump.

In the 90k psi parts of a waterjet pump, the poppet pin is typically located within the hydraulic valve assembly. When the pump is in operation, the poppet pin moves back and forth within the valve assembly, opening and closing ports to allow water to flow through the pump and to the cutting head.

1. Design

The poppet pin is a small, cylindrical rod that is used to control the flow of high-pressure water in the pump. The poppet pin is designed to withstand extreme pressures and hydraulic forces, and it is typically made from a high-strength material, such as hardened steel or tungsten carbide. The poppet pin is also precision-machined to ensure that it fits within the hydraulic valve assembly with a high degree of accuracy and minimal clearance. The pin may be coated or treated with a special surface finish to enhance its resistance to wear, corrosion, or other forms of damage.

2. Maintenance and inspection

Over time, the poppet pin may wear or become damaged, which can lead to leaks, reduced flow rates, or other problems. Signs of wear or damage to the poppet pin may include visible wear or deformation, irregular movement within the valve assembly, or a decrease in the flow rate of the waterjet pump.

Regular maintenance and inspection of the poppet pin and other 90k psi parts is essential for ensuring that the waterjet pump operates safely and efficiently. This may include cleaning, lubrication, and replacement of worn or damaged components.

3. Replacement

When replacing the poppet pin, it is important to choose the 90k psi parts that are designed to meet the specific requirements of the waterjet pump. Using an incorrect or inferior replacement part can lead to leaks, reduced flow rates, or other problems.

4. Safety considerations

Working with high-pressure hydraulic systems, such as those used in 90k psi waterjet pumps, can be dangerous. It is important to follow proper safety procedures when working with the poppet pin or any other component of the waterjet pump to avoid injury or equipment damage.