Descripción

El bushing retainer flange 72175989 is a component used in the 90000 psi waterjet pump.

This flange is used to secure the bushing retainer in place, which helps to prevent the bushing from rotating during operation.

The bushing itself is a critical component of the 90000 psi waterjet pump, as it helps to support the high-pressure seals and prevent leaks.

The bushing retainer flange 72175989 is typically made of high-strength steel and is designed to withstand the extreme pressures and forces generated by the 90000 psi waterjet pump.

It is often precision-machined to ensure a tight fit with the bushing retainer and to prevent any movement or rotation during operation.

The bushing retainer is typically a cylindrical component that is located on the high-pressure side of the 90000 psi waterjet pump, and it is designed to fit snugly into the pump housing.

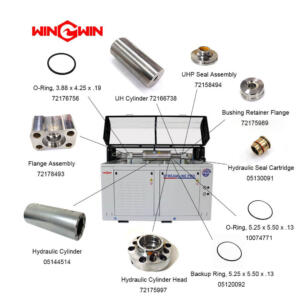

Artículo | Número de pieza | Descripción | Cantidad | Artículo | Número de pieza | Descripción | Cantidad |

1 | 05146592 | Junta, soporte de Topworks | 2 | 14 | 72162253 | Desatascador | 2 |

2 | 20476377 | Soporte, Topworks | 2 | 15 | 05130091 | Cartucho de sello hidráulico | 2 |

3 | 10118206 | Junta tórica, 1.31×1.56× .13 | 2 | 16 | 72175989 | Brida de retención de buje | 2 |

4 | 05144514 | Cilindro hidráulico | 1 | 17 | 72158494 | Conjunto de sello UHP | 2 |

5 | 05098991 | Tornillo de cabeza de zócalo, 3/8-16×3-3/4 | 8 | 18 | 72166738 | Cilindro UHP | 2 |

6 | 95688743 | Arandela de cerradura, .38 | 8 | 19 | 72163802 | Liner | 2 |

7 | 72101190 | Conjunto de pistón | 1 | 20 | 20474325 | Stud, 1-1/8-12×18.31 | 8 |

8 | 10074771 | Junta tórica, 5.25×5.50× .13 | 2 | 21 | 72170157 | Conjunto de cabezal de sellado | 2 |

9 | 05120092 | Anillo de respaldo, 5.25×5.50× .13 | 2 | 22 | 72178493 | Montaje de brida | 2 |

10 | 72175997 | Culata hidráulica | 2 | 23 | 20464590 | Lavadora plana, 1.13 | 8 |

11 | 05097886 | Tornillo de cabeza de zócalo, 3/4-16×2-1/4 | 12 | 24 | 20461761 | Tuerca hexagonal, 1-1/8-12 | 8 |

12 | 05144183 | Conjunto del espaciador, interruptor de proximidad | 2 | 25 | 20489339 | Adaptador, JIC/tubería, 50× .38 | 1 |

05144191 | Junta tórica, .69× .88× .09 | 26 | 72176756 | Junta tórica, 3.88×4.25× .19 | 6 | ||

13 | 72141569 | Kit, interruptor de proximidad | 2 | ||||

| 72134224 | Interruptor de proximidad | ||||||

95119012 | Tornillo de cabeza de zócalo, 1/4-20×1 |

What are some common issues that can arise with the bushing retainer flange in the 90000 psi waterjet pump?

1. Wear and tear

The bushing retainer flange is a high-stress component that is subjected to significant forces and pressures during operation.

Over time, this can cause the flange to experience wear and tear, which can lead to degradation or failure.

Wear and tear can be caused by friction, corrosion, or other factors that can cause the flange to degrade over time.

2. Improper installation

Proper installation of the bushing retainer flange is critical for ensuring that it functions properly.

If the flange is not installed correctly or is not tightened to our specifications, it can cause issues with the operation of the 90000 psi waterjet pump.

This can include leaks, reduced performance, or even damage to other components of the 90000 psi waterjet pump.

3. Misalignment

The bushing retainer flange must be properly aligned with other components of the 90000 psi waterjet pump in order to function correctly.

If there is misalignment, it can cause excessive wear and tear on the flange and other components, leading to poor performance or even damage to the pump.

Misalignment can be caused by improper installation or other issues with the 90000 psi waterjet pump.

4. Overheating

Overheating of the waterjet pump can cause damage to the bushing retainer flange and other components of the 90000 psi waterjet pump.

Overheating can be caused by a variety of factors, including blockages, misalignment, or other issues that are preventing the 90000 psi waterjet pump from functioning properly.

Overheating can cause the flange to warp or otherwise fail, leading to leaks or reduced performance.

5. Fatigue

The bushing retainer flange is subjected to high cyclic loading during operation, which can lead to fatigue failure over time.

This can be addressed through proper design and material selection, as well as regular inspection and maintenance.

Fatigue failure can cause the flange to crack, deform, or otherwise fail, leading to leaks or reduced performance

What are some signs of wear or damage to look for in the bushing retainer flange?

1. Corrosion

Corrosion can cause the bushing retainer flange to become weakened or compromised, which can lead to leaks or other issues with the 90000 psi waterjet pump.

Signs of corrosion can include discoloration, pitting, or other visible damage to the surface of the flange.

2. Cracks or fractures

The bushing retainer flange may develop cracks or fractures over time, especially if it is subjected to significant stress or fatigue.

Signs of cracks or fractures can include visible damage or deformations in the flange, or leaks around the flange.

3. Warping

The bushing retainer flange may warp or deform if it is exposed to excessive heat or stress.

Warping can cause the flange to become misaligned or otherwise compromised, leading to issues with the operation of the 90000 psi waterjet pump.

4. Wear or scoring

The bushing retainer flange may experience wear or scoring over time, especially if it is exposed to abrasive particles or other contaminants.

This wear or scoring can cause the flange to become rough or uneven, leading to leaks or other issues with the 90000 psi waterjet pump.

5. Loose or damaged fasteners

The bushing retainer flange is typically secured to other components of the 90000 psi waterjet pump using fasteners.

If these fasteners become loose or damaged, it can cause the flange to become misaligned or compromised, leading to issues with the 90000 psi waterjet pump.

6. Leaks

If there are leaks around the bushing retainer flange, it could be a sign that there is wear or damage to the flange or other components of the 90000 psi waterjet pump.

Regular inspection and maintenance of the bushing retainer flange and other components of the 90000 psi waterjet pump is critical for ensuring reliable and efficient operation.

This can include checking for signs of wear or damage to the flange or bushing retainer, as well as ensuring that they are properly installed and tightened to our specifications.

The specific components and specifications of a 90000 psi waterjet pump can vary depending on the manufacturer and model of the pump.

If you have specific questions or concerns about the bushing retainer flange or other components of a waterjet pump, it is recommended to consult our documentation or contáctenos para obtener asistencia.