Descripción

Introducción

High pressure water cutting is a popular technology used for cutting various materials, such as metal, stone, and glass.

Waterjet cutting is a precise and efficient technology that utilizes high-pressure water to erode various materials, resulting in clean and accurate cuts.

However, to achieve such high pressure, the 90000 psi waterjet pump must have a reliable water pump to ensure that the coolant is circulated effectively throughout the system.

The market offers a variety of water pumps, but the Water Pump 20481206 is recognized as one of the most reliable and durable options available.

Description and Features

The Water Pump 20481206 is specifically designed to endure the demands of high-pressure water cutting applications.

Its construction from high-strength stainless steel ensures that it can withstand harsh environments and resist corrosion.

The pump circulates coolant from the radiator to the engine and back, maintaining optimal temperatures and preventing overheating and potential damage.

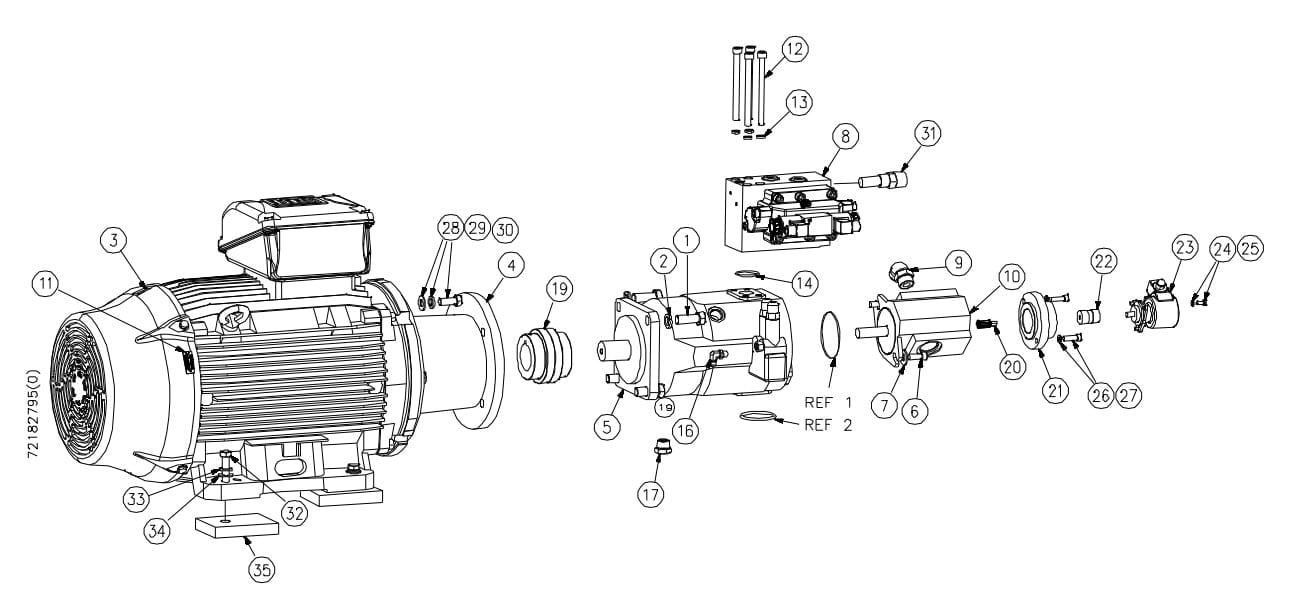

Artículo | Número de pieza | Descripción | Cantidad | Artículo | Número de pieza | Descripción | Cantidad |

1 | 61125453 | Hex Head Screw, 3/4-10 x 2-1/4 | 4 | 20 | 05103429 | Spline Shaft | 1 |

2 | 95688735 | Lock Washer, .75 | 8 | 21 | 05103411 | Adapter, Water Pump | 1 |

3 | 72153521 | Electric Motor, 60 HP | 1 | 22 | 05103395 | Shaft Coupling | 1 |

4 | 10082022 | Flange, Motor/Pump | 1 | 23 | 20481206 | Water Pump | 1 |

5 | 05103239 | Piston Pump | 1 | 24 | 95838314 | Arandela de cerradura, .25 | 3 |

6 | 10192961 | Socket Head Screw, M12 x 1.75 x 30MM | 2 | 25 | 95572897 | Socket Head Screw, 1/4-20 x 5/8 | 3 |

7 | 10069763 | Flat Washer, .50 | 2 | 26 | 95750394 | Arandela de cerradura, .38 | 2 |

8 | 72159791 | Manifold Assembly, D08 | 1 | 27 | 05041033 | Socket Head Screw, 3/8-16 x 1-1/4 | 2 |

9 | 80086150 | Adapter, ORB/JIC, 1.0 x 1.0 | 1 | 28 | 95897294 | Hex Head Screw, 5/8-11 x 1-1/2 | 4 |

10 | 05091301 | Bomba hidráulica | 1 | 29 | 95688719 | Lock Washer, .63 | 4 |

11 | 10091510 | Arrow Decal | 1 | 30 | 80087513 | Flat Washer, .63 | 4 |

12 | 05103247 | Socket Head Screw, 1/2-13 x 6 | 4 | 31 | 20469936 | Relief Valve Assembly, 180 Bar | 1 |

13 | 95688750 | Arandela de cerradura, .50 | 4 | 32 | 95897286 | Hex Head Screw, 5/8-11 x 3 | 4 |

14 | 49882087 | O-Ring, 1.88 x 2.13 x .13 | 1 | 33 | 95688719 | Lock Washer, .63 | 4 |

16 | 05085758 | Adapter, ORB/JIC, .38 x .25 | 1 | 34 | 80087513 | Flat Washer, .63 | 4 |

17 | 10118057 | Plug, ORB, .75 | 1 | 35 | 20484771 | Motor Mount | 4 |

19 | 72158528 | Coupling, Flexible Drive | 1 | Ref 1 | 05112727 | O-Ring, 104MM x 3MM | — |

| Ref 2 | 49891195 | O-Ring, 2.75 x 3.0 x .13 | — |

Function of Water Pump in 90000 psi Waterjet Pump

The Water Pump 20481206 is a crucial component of the 90000 psi waterjet pump.

It ensures that the coolant is circulated effectively throughout the system, which is essential for maintaining optimal operating temperatures and preventing damage from overheating.

A water pump that is not functioning correctly can potentially cause the system to overheat and lead to costly repairs and downtime.

In addition to preventing overheating, the Water Pump 20481206 helps to minimize the risk of downtime and costly repairs by ensuring that the pump operates smoothly and efficiently.

Water pumps that are not functioning correctly can develop leaks or other issues that can lead to the pump’s failure.

PSI for Waterjet Cutting

The pressure of the water used in waterjet cutting can vary based on several factors, including the thickness and type of abrasive material used, as well as the type of steel being cut.

Typically, water pressure ranging between 20,000 psi and 55,000 psi is required for cutting metal with waterjet.

However, with the Water Pump 20481206, the 90000 psi waterjet pump can generate significantly higher pressure water output, enabling it to cut through materials with greater ease and precision.

The higher the water pressure, the faster the cutting speed, and the greater the material thickness that can be cut.

The distance between the nozzle and the material’s surface is a critical factor that affects the pressure applied to the material during waterjet cutting.

The closer the nozzle is to the surface, the higher the pressure applied, and the faster the cutting speed.

Metal Suitable for High-Pressure Applications

Choosing the right metal for high-pressure applications is critical, as it can affect the durability, efficiency, and safety of the system.

Titanium is an ideal metal for high-pressure applications due to its impressive strength, ease of maintenance, and resistance to corrosion.

Titanium has a good tensile strength, ranging from 30,000 to 200,000 psi, making it suitable for use in high-pressure water cutting applications.

It is also lightweight, which makes it easier to handle and transport.

The corrosion-resistant properties of titanium make it an ideal metal for waterjet cutting applications.

Water Intensifier Pump

The Water Intensifier Pump is another critical component of the 90000 psi waterjet pump.

It is responsible for increasing the pressure of the hydraulic oil in the system, enabling the waterjet pump to generate higher pressure water output, which is essential for effective cutting.

The Water Intensifier Pump works by boosting the pressure of the hydraulic oil, which in turn increases the pressure of the water in the system.

This helps to ensure that the waterjet pump operates at optimal pressures, enabling it to achieve precise cutting results.

Importance of Choosing the Right Water Pump for 90000 psi Waterjet Pump

Choosing the right water pump for the 90000 psi waterjet pump is essential for ensuring optimal performance and minimizing the risk of downtime and costly repairs.

The Water Pump 20481206 is an ideal choice for high-pressure water cutting applications, thanks to its robust construction and reliable performance.

In addition, the Water Intensifier Pump plays a critical role in ensuring that the waterjet pump operates at optimal pressures, enabling it to achieve precise cutting results.

By choosing the right water pump and water intensifier pump, you can help to ensure that your waterjet pump operates smoothly and efficiently, delivering precise and clean cuts every time.

Maintenance of Water Pump 20481206

To ensure the Water Pump 20481206 functions correctly, it is essential to perform regular maintenance.

Regular maintenance can help to prolong the life of the pump and minimize the risk of downtime and costly repairs.

Some of the maintenance tasks that should be performed include checking the coolant level, inspecting the hoses for leaks or damage, checking the radiator for debris or blockages, and inspecting the water pump for damage or leaks.

To ensure proper functioning, it is crucial to periodically replace the coolant in the water pump.

Factors to Consider When Choosing a Water Pump for 90000 PSI Waterjet Cutting

1. The pump capacity is an important consideration as it determines how much coolant the pump can circulate and how quickly it can do so.

A pump with a higher capacity will be able to circulate more coolant, which can help to prevent overheating and ensure optimal performance.

2. The pressure rating of a water pump is a significant consideration since it determines the amount of pressure that the pump can generate.

For waterjet cutting applications, a pump with a high-pressure rating is essential for achieving precise and clean cuts.

3. Durability is another crucial factor to consider when selecting a water pump.

High-quality materials that can resist corrosion, wear, and tear are essential for ensuring longevity and proper functioning.

This will help to ensure that the pump lasts longer and performs better, minimizing the risk of downtime and costly repairs.

4. When selecting a water pump, it is vital to ensure that it is compatible with the cutting system and its components.

The water pump should be compatible with the waterjet cutting system and its components, including the Water Intensifier Pump and other accessories.

5. Cost is an essential consideration when selecting a water pump that meets specific requirements while remaining within budget.

It is important to choose a pump that is within your budget while still meeting your requirements for capacity, pressure rating, durability, and compatibility.

Conclusión

The Water Pump 20481206 is a vital component of the 90000 psi waterjet pump, responsible for circulating coolant throughout the engine’s cooling system and maintaining optimal temperatures, preventing damage and downtime.

Choosing the right water pump for the 90000 psi waterjet pump, such as the Water Pump 20481206, can help to ensure that your waterjet pump operates smoothly and efficiently, minimizing the risk of downtime and costly repairs.

With the addition of a Water Intensifier Pump, the 90000 psi waterjet pump can generate significantly higher pressure water output, enabling it to cut through materials with greater ease and precision.

By choosing the right water pump and water intensifier pump, you can help to ensure that your waterjet pump operates at optimal pressures, delivering precise and clean cuts every time.

To ensure the Water Pump 20481206 functions correctly, regular maintenance is essential.

It is important to check the coolant level, inspect the hoses and radiator for damage or debris, and periodically replace the coolant.

When selecting a water pump for a waterjet cutting application, it is important to consider factors such as pump capacity, pressure rating, durability, compatibility, and cost.

By taking these factors into consideration, you can select the right water pump for your specific needs, ensuring optimal performance and minimizing the risk of downtime and costly repairs.

Any other requirements for 90000 psi waterjet intensifier pump or high pressure water cuttingPor favor contáctenos.