Descripción

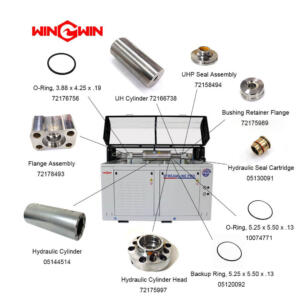

90000 psi Pump Parts: Hydraulic Seal Cartridge 05130091

A hydraulic seal cartridge is one of the 90000 psi pump parts used in some models of waterjet pumps to help prevent leaks and maintain pressure in the hydraulic system.

The seal cartridge is typically located in the hydraulic cylinder of the pump and is designed to fit snugly around the piston or ram.

The hydraulic seal cartridge typically consists of several individual seals that work together to create a tight seal around the piston or ram.

The seals are typically made of high-quality materials that are resistant to wear, corrosion, and other forms of degradation.

Some common materials used in hydraulic seals include nitrile rubber, polyurethane, and PTFE.

The hydraulic seal cartridge is designed to be easily replaceable, which can help to reduce downtime and maintenance costs.

When the seals in the cartridge become worn or damaged, the entire cartridge can be replaced, rather than having to replace each individual seal.

Artículo | Número de pieza | Descripción | Cantidad | Artículo | Número de pieza | Descripción | Cantidad |

1 | 05146592 | Junta, soporte de Topworks | 2 | 14 | 72162253 | Desatascador | 2 |

2 | 20476377 | Soporte, Topworks | 2 | 15 | 05130091 | Cartucho de sello hidráulico | 2 |

3 | 10118206 | Junta tórica, 1.31×1.56× .13 | 2 | 16 | 72175989 | Brida de retención de buje | 2 |

4 | 05144514 | Cilindro hidráulico | 1 | 17 | 72158494 | Conjunto de sello UHP | 2 |

5 | 05098991 | Tornillo de cabeza de zócalo, 3/8-16×3-3/4 | 8 | 18 | 72166738 | Cilindro UHP | 2 |

6 | 95688743 | Arandela de cerradura, .38 | 8 | 19 | 72163802 | Liner | 2 |

7 | 72101190 | Conjunto de pistón | 1 | 20 | 20474325 | Stud, 1-1/8-12×18.31 | 8 |

8 | 10074771 | Junta tórica, 5.25×5.50× .13 | 2 | 21 | 72170157 | Conjunto de cabezal de sellado | 2 |

9 | 05120092 | Anillo de respaldo, 5.25×5.50× .13 | 2 | 22 | 72178493 | Montaje de brida | 2 |

10 | 72175997 | Culata hidráulica | 2 | 23 | 20464590 | Lavadora plana, 1.13 | 8 |

11 | 05097886 | Tornillo de cabeza de zócalo, 3/4-16×2-1/4 | 12 | 24 | 20461761 | Tuerca hexagonal, 1-1/8-12 | 8 |

12 | 05144183 | Conjunto del espaciador, interruptor de proximidad | 2 | 25 | 20489339 | Adaptador, JIC/tubería, 50× .38 | 1 |

05144191 | Junta tórica, .69× .88× .09 | 26 | 72176756 | Junta tórica, 3.88×4.25× .19 | 6 | ||

13 | 72141569 | Kit, interruptor de proximidad | 2 | ||||

| 72134224 | Interruptor de proximidad | ||||||

95119012 | Tornillo de cabeza de zócalo, 1/4-20×1 |

What are some common causes of hydraulic seal cartridge damage?

1. High pressure

90000 psi pump parts of hydraulic systems typically operate at high pressures, which can put a lot of stress on the seal cartridge.

As time passes, this pressure can cause the seal to wear out or fail.

2. Contamination

If the hydraulic fluid becomes contaminated with dirt, debris, or other particles, it can cause damage to the seal cartridge.

Contaminants can get past the seal and cause it to wear out or fail prematurely.

3. Improper installation

If the seal cartridge is not installed correctly, it can cause damage to the seal or housing. This can lead to fluid leaks or decreased performance.

4. Chemical exposure

Some hydraulic systems use fluids that are harsh or corrosive. Exposure to these chemicals can cause damage to the seal cartridge over time.

5. Temperature extremes

Hydraulic systems can be exposed to extreme temperatures, which can cause the seal cartridge to expand or contract. Over time, this can cause the seal to wear out or fail.

6. Age

Like all mechanical components, hydraulic seal cartridges have a limited lifespan. All 90000 psi pump parts will suffer from normal wear and tear after prolonged use.

What are some common causes of improper installation or alignment of the hydraulic seal cartridge?

1. Incorrect seal size

Using the wrong size seal for your 90000 psi pump parts ofhydraulic system can also cause improper installation or alignment.

Make sure to select the correct seal size based on the dimensions of the housing and shaft.

2. Poor seal placement

Improper placement of the seal can cause it to be misaligned, leading to damage or wear.

Make sure to place the seal in the correct location and orientation, and check it for correct fit.

3. Over-tightening or under-tightening

Tightening the seal cartridge too much or too little can cause improper alignment or damage to the seal.

4. Dirt or debris in the housing

Dirt, debris, or other contaminants in the housing can cause improper alignment or damage to the seal.

Make sure to clean the surfaces with a suitable solvent and a lint-free cloth before installation.

5. Worn or damaged housing

Uneven or damaged surfaces on the housing or shaft can cause improper alignment or damage to the seal.

6. Improper assembly or disassembly

Improper assembly or disassembly of the 90000 psi pump parts in hydraulic system can cause improper alignment of the seal cartridge.

Make sure to follow proper procedures when assembling or disassembling the system.

7. Lack of lubrication

Lack of lubrication can cause the seal to become misaligned or damaged.

Make sure to lubricate the seal and housing properly before installation.

8. Improper storage

If the seal cartridge is stored improperly, it can become misshapen or damaged, causing improper alignment.

Make sure to store the seal cartridge in a dry, clean, and temperature-controlled environment.

Some common issues that can arise with hydraulic seal cartridges of 90000 psi pump parts include leaks, reduced pressure, and poor performance.

These issues can be caused by wear or damage to the seals, improper installation, or other issues with 90000 psi pump parts of the hydraulic system.

Proper installation and maintenance of the hydraulic seal cartridge is critical for ensuring the reliable and efficient operation of the waterjet pump.

This can include regular inspection of the cartridge for signs of wear or damage, as well as replacement of any worn or damaged 90000 psi pump parts as needed.

Any other questions, please contáctenos.