Descripción

The Cylinder Head BV601184 is a component used in some high-pressure waterjet pumps, specifically those that are designed to operate at pressures up to 90000 psi.

The cylinder head is a critical component in the 90000 psi waterjet pump, as it is responsible for holding the high-pressure water in the cylinder and directing it to the nozzle.

The cylinder head typically includes inlet and outlet ports, as well as a series of valves and seals that help to control the flow of water and prevent leaks.

The Cylinder Head BV601184 is typically made of a high-strength material, such as stainless steel or titanium, that is capable of withstanding the high pressures and stresses involved in the operation of the waterjet pump.

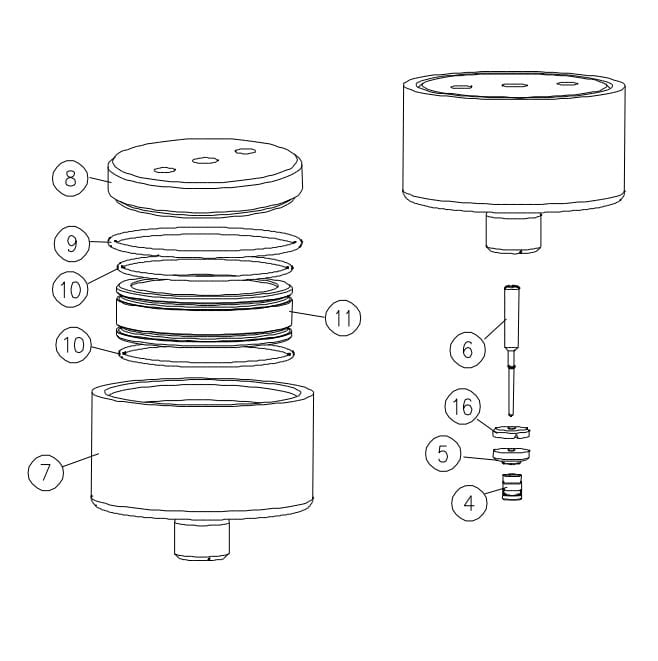

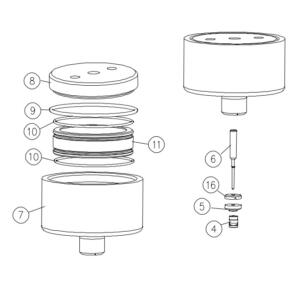

Artículo | Número de pieza | Descripción | Cantidad | Artículo | Número de pieza | Descripción | Cantidad |

1 | 20468617 | Valve Body | 1 | 9 | 10074714 | O-Ring, 2.44 x 2.63 x .09 | 1 |

2 | 10178697 | Valve Seat | 1 | 10 | 10074565 | O-Ring, 2.25 x 2.38 x .06 | 2 |

3 | 20451557 | UHP Adapter | 1 | 11 | BV501184 | Pistón | 1 |

4 | 72112069 | Montaje del sello | 1 | 12 | 20452965 | Collar UHP, .38 | 1 |

5 | 20475874 | Backup Ring, Bronze | 1 | 13 | 20452956 | Glándula UHP, .38 | 1 |

6 | 20475878 | Valve Stem | 1 | 14 | 20452959 | UHP Collar, .25 | 1 |

7 | 20468601 | Pneumatic Cylinder | 1 | 15 | 20452962 | UHP Gland, .25 | 1 |

8 | BV601184 | Cylinder Head | 1 | 16 | 20475882 | Backup Ring, SST | 1 |

| 20477518 | Kit de piezas de repuesto | ||||||

| Includes items 2, 4, 5, 6, 9, 10 and 16 |

What are the signs and reasons that the cylinder head in 90000 psi pump is overheating?

1. Causes of overheating

There are several factors that can contribute to cylinder head overheating in 90000 psi waterjet pumps.

These may include low water flow rates, high ambient temperatures, issues with the pump’s cooling system, or problems with the water supply.

2. Performance issues

One of the most common signs of cylinder head overheating is a decrease in the performance of the waterjet pump.

This may manifest as a reduction in the pressure or flow rate of the water being delivered by the pump.

If you notice that the pump is not performing as well as it usually does, it may be a sign that the cylinder head is overheating.

3. Aumento del ruido

Overheating can cause the pump to operate at a higher noise level than usual.

This can be due to increased friction and stress on the pump’s components.

If you notice that the pump is louder than usual, it may be a sign that the cylinder head is overheating.

4. Leaks

Overheating can cause damage to the seals and valves in the cylinder head, which can lead to leaks.

If you notice water leaking from the cylinder head or other components of the pump, it may be a sign that the cylinder head is overheating.

5. High temperature readings

Monitoring the temperature of the cylinder head can help to identify overheating issues before they cause more serious problems.

If you notice that the temperature of the cylinder head is higher than normal, it may be a sign that the cylinder head is overheating.

It’s important to monitor the temperature of the cylinder head regularly to ensure that it is operating within safe temperature limits.

6. Burning smells

Overheating can also cause a burning or metallic smell to emanate from the waterjet pump.

This can be due to the overheating of metal components in the pump or the burning of seals or other materials.

7. Cooling system issues

In some cases, the cause of cylinder head overheating may be due to issues with the pump’s cooling system.

This can include problems with the water supply, such as low water flow rates or contaminants in the water that can clog the cooling system.

It’s important to ensure that the cooling system is functioning properly and that the water supply is clean and free of contaminants.

8. Ambient temperature

High ambient temperatures can also contribute to cylinder head overheating, particularly if the waterjet pump is operating in a hot environment.

Ensuring that the pump is properly ventilated and that the ambient temperature is within acceptable limits can help to prevent overheating.

What are some common contaminants that can damage the cylinder head in 90000 psi waterjet pump?

There are several types of contaminants that can potentially enter the water supply and cause damage to the cylinder head in the 90000 psi waterjet pump.

Here are some of the most common contaminants that can damage the cylinder head:

1. Dirt and debris

Dirt and debris can cause damage to the seals and valves in the cylinder head, leading to leaks or reduced performance.

These contaminants can enter the water supply from a variety of sources, such as groundwater or surface water.

Installing a sediment filter or other type of filter can remove particles from the water supply.

2. Abrasive particles

If the water supply contains abrasive particles, such as sand or sediment, they can cause damage to the seals and valves in the cylinder head over time.

This can lead to leaks or reduced performance of the 90000 psi waterjet pump.

To prevent damage from abrasive particles, it’s important to ensure that the water supply is properly filtered.

In addition, it may be necessary to periodically flush the system to remove any buildup of abrasive particles.

3. Chemicals

Certain chemicals in the water supply can cause damage to the seals and valves in the cylinder head.

This may include chemicals such as chlorine or other disinfectants that are added to the water supply for treatment purposes.

4. Algae and bacteria

Algae and bacteria can grow in the water supply and cause damage to the cylinder head if they are not properly treated.

Algae and bacteria can cause clogs in the cooling system and may also contribute to corrosion of the cylinder head.

5. Scale buildup

Scale buildup can occur if the water supply contains high levels of minerals such as calcium and magnesium.

To prevent damage from scale buildup, it’s important to periodically clean the system and remove any buildup of minerals.

Installing a water softener or other type of treatment system can also help to prevent scale buildup.

6. Oil and grease

If oil or grease enters thewater supply, it can cause damage to the cylinder head and other components of the 90000 psi waterjet pump.

Oil and grease can cause clogs in the cooling system and may also lead to decreased performance of the 90000 psi waterjet pump.

7. Rust and corrosion

Rust and corrosion can occur in the cylinder head if it is made of materials that are not resistant to corrosion or if the water supply contains corrosive materials.

This can lead to leaks or reduced performance of the 90000 psi waterjet pump over time.

What is the expected lifespan of the cylinder head used in 90000 psi waterjet pump?

The expected lifespan of a cylinder head in the 90000 psi waterjet pump can vary depending on several factors, including the quality of the materials used, the operating conditions of the pump, and the level of maintenance that is performed.

In general, a well-maintained cylinder head can last for several years, typically around 5 to 10 years.

Factors that can impact the lifespan of the cylinder head include the type of materials that it is made from, the level of corrosion resistance of those materials, and the operating conditions of the waterjet pump.

If the cylinder head is made from high-quality materials that are resistant to corrosion and wear, and if it is properly maintained and operated within its recommended operating range, it can last for many years.

However, if the waterjet pump is not properly maintained or if maintenance tasks are not performed on a regular basis, this can also reduce the lifespan of the cylinder head.

To maximize the lifespan of the cylinder head, it’s important to follow the manufacturer’s recommended maintenance schedule and procedures, use high-quality materials in the construction of the cylinder head, and operate the waterjet pump within its recommended operating range.

By taking these steps, you can help to ensure that the cylinder head and other components of the waterjet pump last for many years and provide reliable and efficient operation.

Any other questions about 90000 psi waterjet pumps or other components, please contáctenos.