Descripción

125 HP piezas de bomba 72101570 asiento

Artículo | Número de pieza | Descripción | Cantidad | Artículo | Número de pieza | Descripción | Cantidad |

1 | 05146592 | Junta, soporte de Topworks | 2 | 14 | 72162253 | Desatascador | 2 |

2 | 20476377 | Soporte, Topworks | 2 | 15 | 05130091 | Cartucho de sello hidráulico | 2 |

3 | 10118206 | Junta tórica, 1.31×1.56× .13 | 2 | 16 | 72175989 | Brida de retención de buje | 2 |

4 | 05144514 | Cilindro hidráulico | 1 | 17 | 72158494 | Conjunto de sello UHP | 2 |

5 | 05098991 | Tornillo de cabeza de zócalo, 3/8-16×3-3/4 | 8 | 18 | 72166738 | Cilindro UHP | 2 |

6 | 95688743 | Arandela de cerradura, .38 | 8 | 19 | 72163802 | Liner | 2 |

7 | 72101190 | Conjunto de pistón | 1 | 20 | 20474325 | Stud, 1-1/8-12×18.31 | 8 |

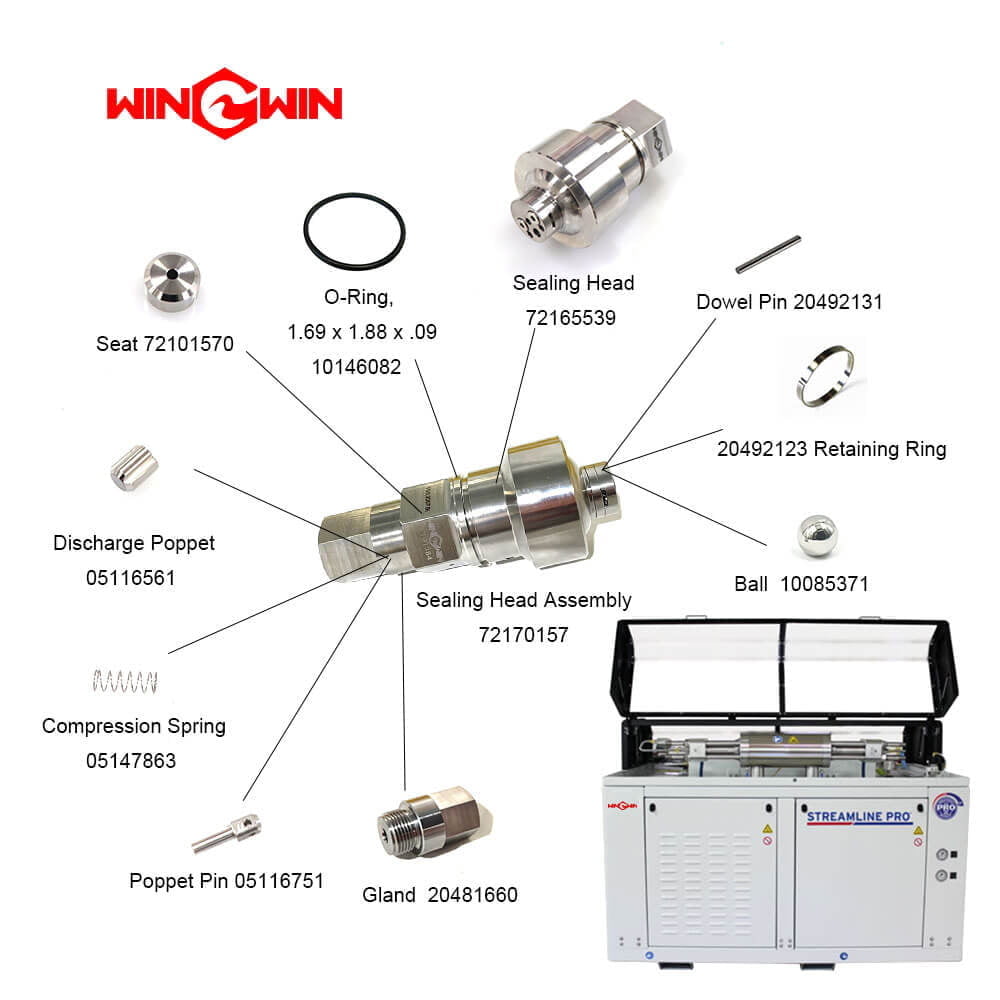

8 | 10074771 | Junta tórica, 5.25×5.50× .13 | 2 | 21 | 72170157 | Conjunto de cabezal de sellado | 2 |

9 | 05120092 | Anillo de respaldo, 5.25×5.50× .13 | 2 | 22 | 72178493 | Montaje de brida | 2 |

10 | 72175997 | Culata hidráulica | 2 | 23 | 20464590 | Lavadora plana, 1.13 | 8 |

11 | 05097886 | Tornillo de cabeza de zócalo, 3/4-16×2-1/4 | 12 | 24 | 20461761 | Tuerca hexagonal, 1-1/8-12 | 8 |

12 | 05144183 | Conjunto del espaciador, interruptor de proximidad | 2 | 25 | 20489339 | Adaptador, JIC/tubería, 50× .38 | 1 |

05144191 | Junta tórica, .69× .88× .09 | 26 | 72176756 | Junta tórica, 3.88×4.25× .19 | 6 | ||

13 | 72141569 | Kit, interruptor de proximidad | 2 | ||||

| 72134224 | Interruptor de proximidad | ||||||

95119012 | Tornillo de cabeza de zócalo, 1/4-20×1 |

Operating Principle of Seat 72101570 in 125 HP Pump Parts:

The seat in 125 HP pump parts is a critical component located in the poppet assembly, and is used to provide a tight seal when the poppet is closed, preventing water from leaking out of the pump and maintaining pressure in the system.

To accomplish this, the seat is typically machined or lapped to a precise tolerance, ensuring a tight fit with the poppet.

When the pump is activated, water is forced into the poppet, which is held closed by a spring or other mechanism. As the pressure builds, the poppet begins to open, allowing water to flow through and into the high-pressure hose.

The seat is typically made from a hard, durable material, such as tungsten carbide, that can withstand the high pressures and abrasive nature of the waterjet stream.

Over time, the high-pressure water stream can cause wear on the seat, particularly on the sealing surfaces. This can result in leaks or reduced efficiency of the pump.

To address this, the seat may need to be replaced or refurbished. Seat refurbishment typically involves machining or lapping the sealing surfaces to restore them to their original condition.

In some cases, the seat may need to be replaced entirely if the wear is too severe.

It is important to regularly inspect the seat and poppet assembly for signs of wear or damage. This can include visible signs of wear or damage on the seat or poppet, as well as leaks or reduced pressure in the 125 HP pump parts system.

Regular maintenance and cleaning can help prevent debris or other contaminants from causing damage to the 125 HP pump parts.

What are the signs of wear on the seat of 125 HP pump parts?

1. Visible wear

The most common sign of wear on the seat is visible wear on the sealing surfaces. This can include scratches, grooves, or other signs of damage that can compromise the seal between the seat and the poppet.

The extent and severity of the wear can vary depending on factors such as usage, maintenance, and the type of material used.

2. Rough or uneven surface

Over time, the surface of the seat can become rough or uneven due to wear or damage. This can prevent the seat from providing a tight seal with the poppet, resulting in leaks or reduced efficiency.

If you run your finger along the surface of the seat and feel roughness or unevenness, this may indicate that the seat needs to be replaced or refurbished.

3. Chipping or cracking

In severe cases, the seat may chip or crack due to wear or damage. This can compromise the integrity of the seat and may require replacement of the entire poppet assembly.

If you notice chipping or cracking on the seat, this is a clear indication that the seat needs to be replaced.

4. Reduced lifespan

The lifespan of a seat can vary depending on factors such as usage, maintenance, and the type of material used.

If you notice that the seat is wearing out faster than expected or needs to be replaced more frequently than usual, this may indicate a problem with the material or other issues that should be addressed.

5. Leaks

If you notice water leaking from the poppet assembly, this may indicate that the seat is worn or damaged. Leaks can be caused by wear on the sealing surfaces of the seat or other damage to the poppet assembly.

6. Reduced pressure or flow

If you notice a decrease in the pressure or flow rate of the waterjet stream, this may indicate a problem with the seat.

Reduced pressure or flow can be caused by wear on the seat or other issues that prevent the seat from providing a tight seal.

Any other questions about 125 HP pump parts, please contáctenos.