What is HPP? How does it work?

HPP stands for High Pressure Processing, also known as Pascalization or high hydrostatic pressure processing. It’s an innovative food preservation technique used to extend the shelf life of foods while maintaining their quality, freshness, and nutritional value.

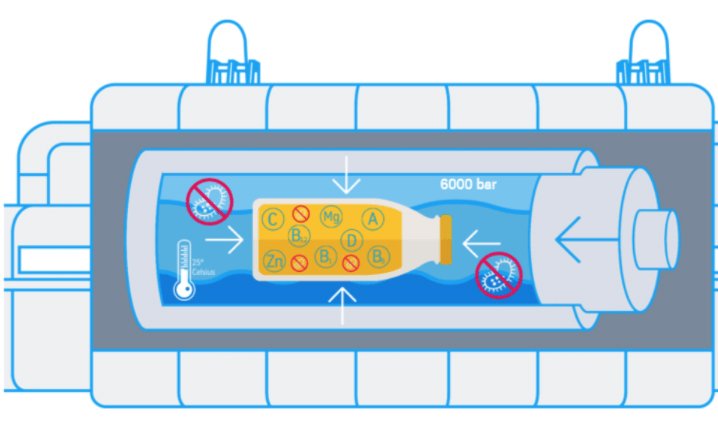

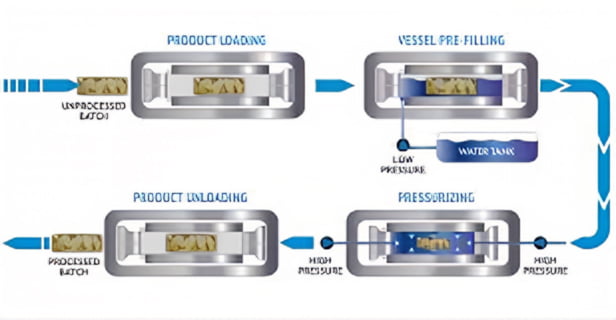

This technique involves subjecting packaged food to exremely high pressure, usually between 87,000 to 130,000 pounds per square inch (psi), for a brief period, ranging from a few seconds to a few minutes. Through this process, the pressure disrupts the cellular structure of harmful bacteria, viruses, yeasts, molds, and otehr pathogens present in the food, rendering them inactive or significantly reducing their presence.

What sets HPP apart is its ability to ensure food safety without relying on high temperatures or chemical additives. Unlike traditional methods, HPP doesn’t involve heat, preserving the food’s natural flavors, colors, and nutritional value. This approach allows food manufacturers to produce safer and higher quality food products while maintaining their sensory attributes.

Commonly applied to various food items such as juices, fruits, vegetables, meats, seafood, and ready-to-eat meals, HPP is favored for its capacity to enhance food safety without compromising the integrity of the product.

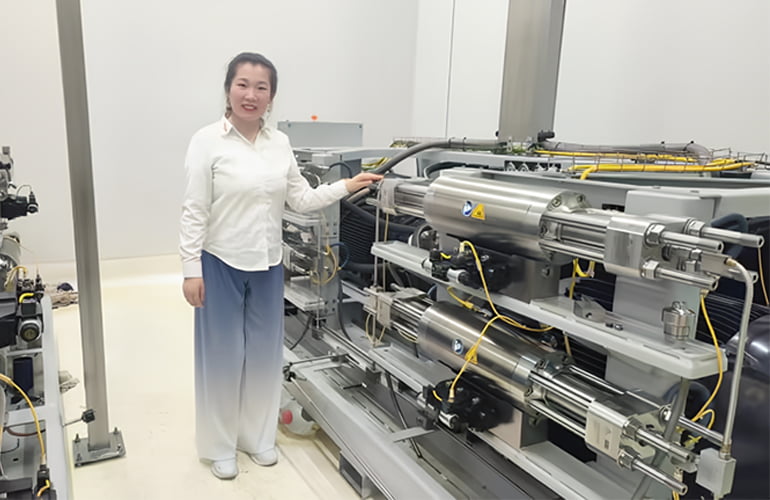

The video shows a pressurizing machine that can achieve this treatment process, also called a Bomba de chorro de agua. This device can also be used to pressurize water for water cutting to achieve the cutting effect:

How does HPP differ from traditional food processing methods?

HPP, or High Pressure Processing, differs significantly from traditional food processing methods in several key ways:

Unlike traditional methods that often involve heat, pasteurization, or chemical additives to preserve food, use this technology relies solely on extremely high pressure to deactivate pathogens. It does not use heat, maintaining the food’s fresh taste, nutrients, and quality.

Traditional methods may involve heat treatments that can sometimes affect the taste, texture, and nutritional content of food. In contrast, it minimizes these alterations, allowing the food to retain its natural characteristics, including flavor and texture.

It ensures food safety by disrupting the cellular structure of bacteria, viruses, yeasts, and molds without compromising the food’s overall quality. Traditional methods might alter the food’s composition or require the use of preservatives, affecting its natural state.

It extends the shelf life of foods by neutralizing harmful microorganisms, thereby reducing the risk of spoilage. Traditional methods might achieve similar results, but they could impact the food’s taste or require the addition of preservatives to maintain freshness.

HPP can be applied to various types of foods, including juices, fruits, vegetables, meats, seafood, and ready-to-eat meals. Traditional methods may have limitations on the types of foods they can effectively process without altering their characteristics.

HPP tends to have a more favorable environmental profile compared to some traditional methods that might involve higher energy consumption or the use of chemicals.

What are the costs associated with HPP? Does it provide economic benefits?

High Pressure Processing (HPP) involves initial costs for specialized equipment and operational expenses like electricity and labor. However, it provides economic benefits by extending product shelf life, reducing food waste, and potentially attracting consumers willing to pay a premium for high-quality, minimally processed items. The technology’s efficiency in processing and the elimination of certain additives contribute to operational savings, offsetting initial investments. Overall, the technology offers a balance between costs and benefits, with long-term advantages in quality, market expansion, and sustainability.

What are the future trends or developments expected in HPP technology?

With the development and progress of science and technology, the lifestyle and rhythm of life in human society have undergone tremendous changes. Time cost accounts for a large part of cost calculation, and the application and popularization of this technology will be more extensive in the future.

Advancements aim to improve the efficiency of High Pressure Processing equipment, reducing processing times while maintaining or improving effectiveness. This could lead to increased throughput and reduced operational costs.

Researchers and food manufacturers are exploring new applications of HPP beyond its current uses in juices, meats, and seafood. This includes exploring its potential in preserving a wider variety of food types, such as dairy products, soups, and sauces.

Innovations in packaging materials and designs compatible with High Pressure Processing are anticipated. This includes developing packaging that can better withstand high pressures while retaining its integrity and ensuring food safety.

There’s a growing interest in adapting High Pressure Processing technology to suit specific food types or production needs. Customized solutions may include adjusting pressure levels, processing times, and parameters to optimize results for different foods.

These trends and developments suggest a promising future for High Pressure Processing technology, with advancements geared towards improving efficiency, expanding applications, and ensuring greater consumer acceptance in the food industry.

Leave us message to get more info about it!