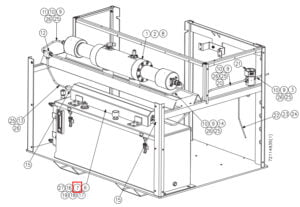

Description

Water Jet Part: Intensifier Assembly

Item number: 72109524

Details: it’s the most important part of the water jet pump, including the water jet part hp cylinder, water jet part hydraulic cylinder, water jet part hp seals, sealing head, piston, plunger etc.

Other water jet part:

| Item number | Description |

| 05059712 | HP Cylinder |

| 20417081 | Sealing Head Assembly |

| 20422243 | HP Seal Assembly |

| 10110393 | Seal Assembly |

| 80086622 | Hydraulic Cartridge Seal Assembly |

| 05007786 | Bushing Retainer Flange |

| 05127584 | Proximity Switch |

FAQ of waterjet cutting machine & water jet part:

How many gallons per minute does a water jet use?

The water as one of the consumption of waterjet cutting machine, which is necessary one. Most waterjet cutting machine will need about 1-2 gpm(3.79-7.57lpm) for cutting. And there will be additional water for the cooling system, due to the waterjet intensifier pump will generate heat after the piston squeeze the hydraulic oil, so the cooling system is necessary, to keep the temperature of the pump keep 20-30 degree, and keep the machine normal work.

Can a waterjet cut Kevlar?

Yes, a waterjet can cut Kevlar. Kevlar is a tough and durable material that is often used in applications where high strength and resistance to abrasion are required, such as in body armor, bulletproof vests, and racing sails.

Waterjet cutting is a popular method for cutting Kevlar because it is a non-thermal cutting process, meaning that no heat is generated during the cutting process, which can help to preserve the properties of the Kevlar material. Additionally, waterjet cutting can produce accurate and precise cuts in Kevlar without fraying or tearing the material.

To cut Kevlar with a waterjet, an abrasive waterjet cutting process is typically used. This involves mixing a high-pressure stream of water with abrasive particles, such as garnet, which helps to increase the cutting power of the waterjet and produce clean, accurate cuts in the Kevlar material.

However, it’s important to note that Kevlar is a very tough and durable material, so the cutting process can be slow and may require multiple passes to achieve the desired cut. Additionally, the thickness of the Kevlar being cut, as well as the complexity of the shape being cut, can also affect the cutting speed and accuracy of the waterjet cutting process. Therefore, it’s always recommended to consult with a professional waterjet cutting service provider to determine the best cutting method for your specific Kevlar cutting needs.