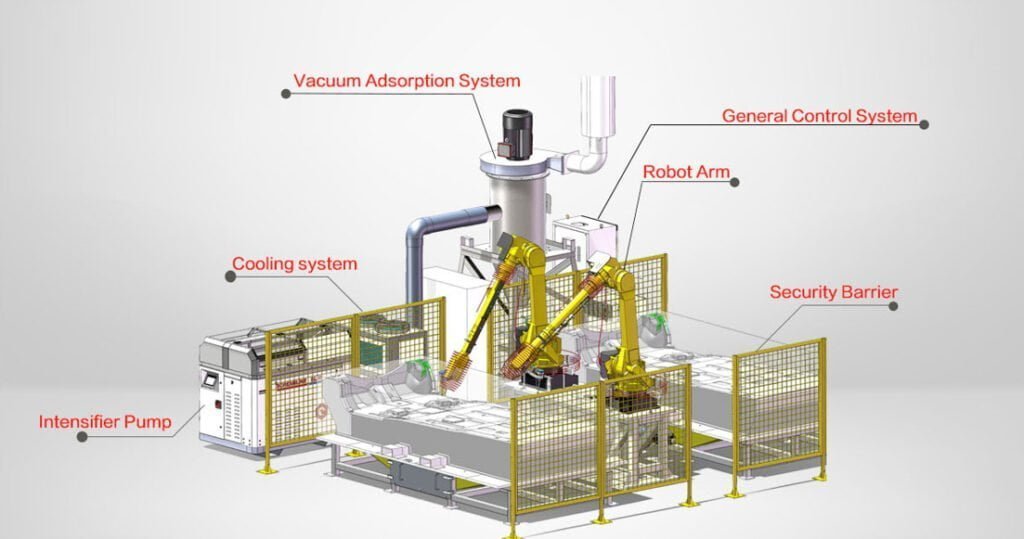

Fanuc M-710iC Robot Waterjet Cutting Machine

| 1 | Brand of robot arm: | Fanuc |

| 2 | Model: | M-710ic |

| 3 | Style: | Pedastal |

| 4 | Quantity of robot arm: | Double |

| 5 | Application: | Automotive interior cutting |

| 6 | Pump type: | Scremline Pro 90k psi |

| 7 | Oprator required: | 2sets |

| 8 | Customize avialable: | Yes |

| 9 | Including devices: | Robot arm, cutting table, high-pressure pump, chiller, control system, etc.. |

Win-Win specializes in providing robot waterjet cutting solutions for automotive interiors, exteriors, aerospace, shipbuilding and other industries, and will customize rationalized and efficient solutions according to customers’ cutting workpieces and requirements.

First of all, we will understand the user’s cutting application, work situation, user needs, etc., so as to design and issue the corresponding scheme rendering. And after discussing with each other, run-in and come up with the final robot waterjet solution, and then put it into practice.

It was like a magic trick, from scratch, the pictures above show us from the design finalized renderings, to the final shape of the actual robot waterjet workstation, which has been assembled and tested, and is about to be shipped to the user’s country.

We can see that this robot waterjet cutting solution matches Win-Win’s SCREAMLINE PRO waterjet high pressure intensifier pump, which is also one of the highlights of this equipment, because it is 90k psi developed and produced by ourselves Intensifier pump, its cutting efficiency is very high, 40%-50% higher than that of 60k psi.

Of course, Win-Win can also provide different brands of robots for water jet cutting solutions, which can be selected according to customer preferences and requirements, or we can recommend them for you. Regarding the model selection of the robot, this requires us to make a rational choice based on the customer’s production needs, such as the robot’s load, arm span, etc., or the robot’s fixing method, such as pedal type, ceiling type or others, or house type, fully enclosed Type, fence type, or two-story design, these all require professional planning and design.

And how to choose a suitable robot waterjet workstation?

This is a more professional issue, which requires the help of very experienced suppliers, of course, it also requires a high degree of cooperation from users and a very clear and understanding of their own production needs.

If you want to design and place a more compact robot waterjet workstion, this may be a factory layout requirement, or the geographical space is limited, please rest assured that we have the type you need, it is the two-story design robot waterjet cutting solution, It not only saves space, but also is a very high-end layout robot waterjet.

If you are more concerned about the noise problem and the sanitation and tidiness of the working environment, then we can choose a fully enclosed house type, which can isolate most of the noise, and can effectively isolate the water splashes that pop up during the robot waterjet cutting work.

Of course, Win-Win can also customize different robot waterjet cutting solutions for various industries, whether you need to cut protective helmets, sports helmets, motorcycle helmets, military helmets, ship hulls, speedboat hulls, or various interiors, Carpet, ceiling, or exterior metal parts, single or multi-layer composite materials, sandwich composite materials, etc., we can cut.

We can make a video call or visit the factory on site to understand our company’s culture, technology, personnel, equipment, strength, etc.

If you have any doubts about our equipment or technology, you are very welcome to study our robot waterjet cutting system. There is a famous saying “Practice is the only criterion for testing truth”, so you are very welcome to send us samples. We will try to see the effect for you, and then we will continue Discuss cooperation matters.

If you are interested in robot waterjet cutting, contact me please.